Do you have a question about the Hyster T5ZAC and is the answer not in the manual?

Covers truck orientation, general safety warnings, and operational guidelines.

Instructions for accessing the drive unit compartment by removing and reinstalling covers.

Guidelines for towing disabled trucks and safely positioning them on blocks.

Essential safety steps for electrical maintenance, including capacitor discharge.

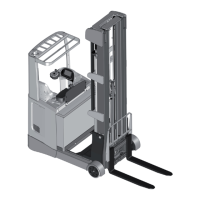

Visual guide and explanation of maintenance points for periodic checks.

Daily checks performed with the key switch in the OFF position, including cleaning compartments.

Procedure for checking the condition and placement of safety labels on the lift truck.

Daily checks for battery electrolyte level, connections, case, and general condition.

Inspection of the truck frame for damage and precautions for welding repairs.

Inspection of drive tires, casters, trail wheels, load wheels, and lift linkage for wear or damage.

Checks for proper operation of the truck's coupler and steering system.

Verification of gauge readings, fuse integrity, and switch functionality.

Daily checks of the hydraulic system for leaks and oil level.

Testing the operation of the two-stage hand brake system.

Lubricating standard and heavy-duty casters according to specified intervals.

Detailed checks and maintenance for the hydraulic system, including oil and breather.

Checking hydraulic oil level, changing oil, and cleaning/replacing the breather cap.

Lubricating the steering column pivot pin, adjusting pin, and lift linkage.

Procedure to check caster alignment and shim requirements due to tire wear.

Instructions for adjusting caster shims to ensure proper wheel contact with the floor.

Procedures for draining, filling, and checking the gear oil level in the master drive unit.

Inspecting the drive tire for damage and verifying wheel bolt torque.

Procedures for removing, inspecting, and installing trail wheel bearings.

Step-by-step guide for changing the hydraulic oil in the C60-80ZAC model.

Safety warnings and required approvals before performing welding on the truck.

Proper procedures and precautions for charging lift truck batteries.

Adjusting battery compartment spacers for secure fit and preventing movement.

Procedures for safely removing and installing batteries using a roller system.

Safety guidelines and steps for using an overhead crane to change batteries.

Instructions for correctly fitting and securing a new replacement battery.

Detailed specifications for battery compartment and battery models for C60ZAC.

Detailed specifications for battery compartment and battery models for C80ZAC.

Detailed specifications for battery compartment and battery models for T5ZAC.

Detailed specifications for battery compartment and battery models for T7ZAC.

| Model | T5ZAC |

|---|---|

| Category | Forklifts |

| Load Capacity | 5000 lbs |

| Power Source | Electric |

| Tire Type | Pneumatic |

| Travel Speed (loaded) | 8.5 mph |