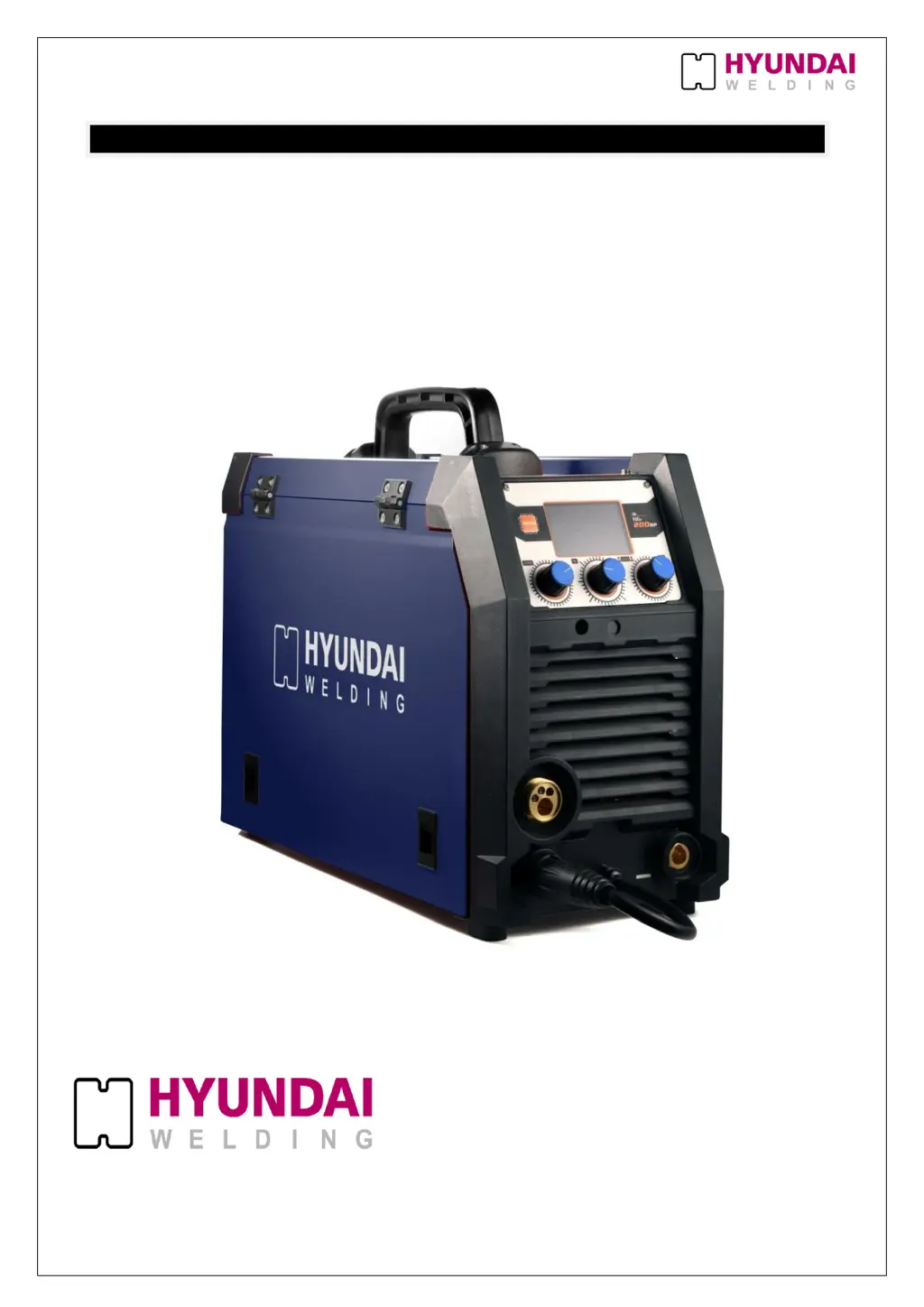

Why is my Hyundai HG200DP Welding System display overheating?

- JJames RhodesAug 5, 2025

Your Hyundai Welding System display might be overheating due to several reasons: the voltage is too high (more than 15%), in which case you should switch off the power source, check the main supply, and restart the welder when the power recovers to a normal state; bad power ventilation leading to overheat protection, so improve the ventilation condition; the circumstance temperature is too high or using over the rated duty-cycle, in these cases it will automatically recover when the temperature cools down.