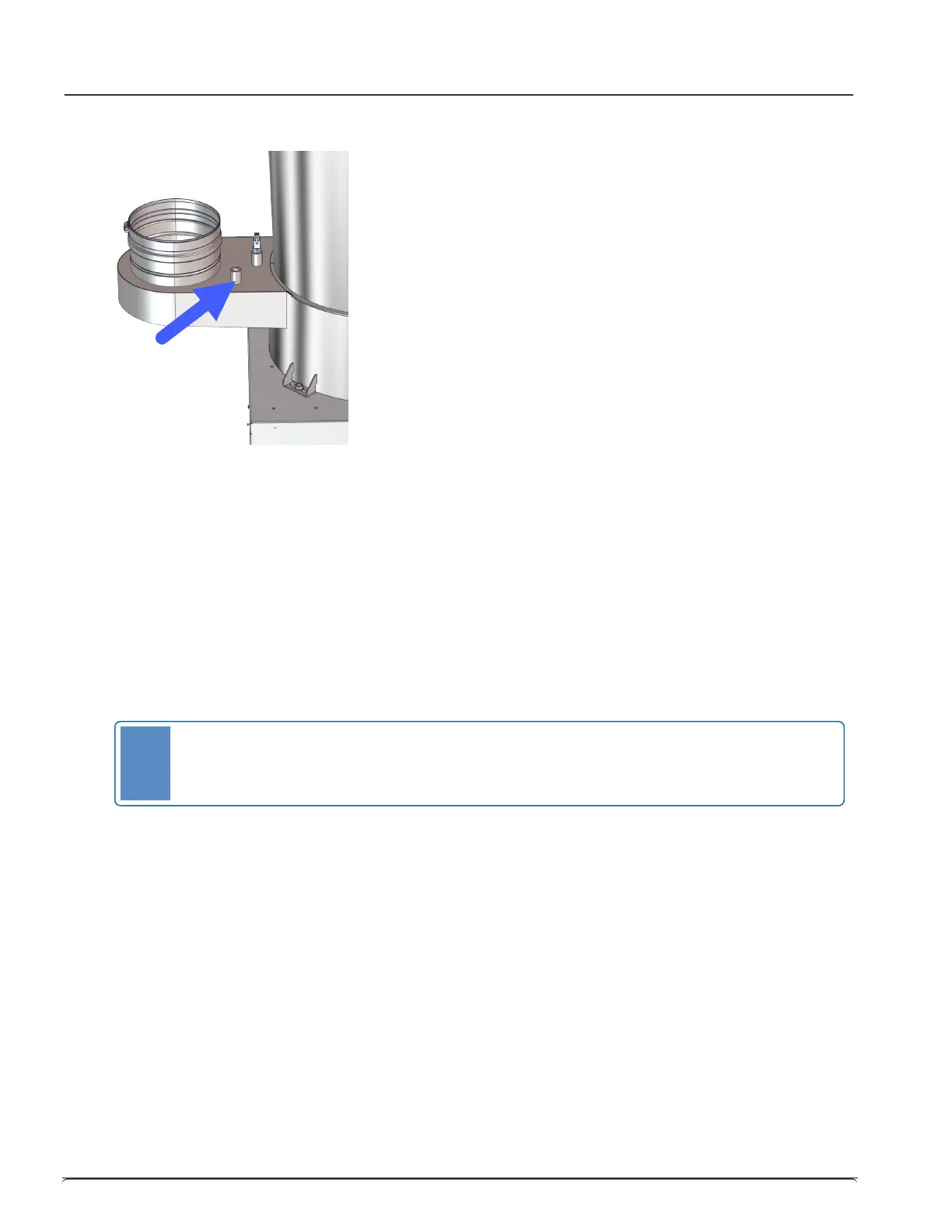

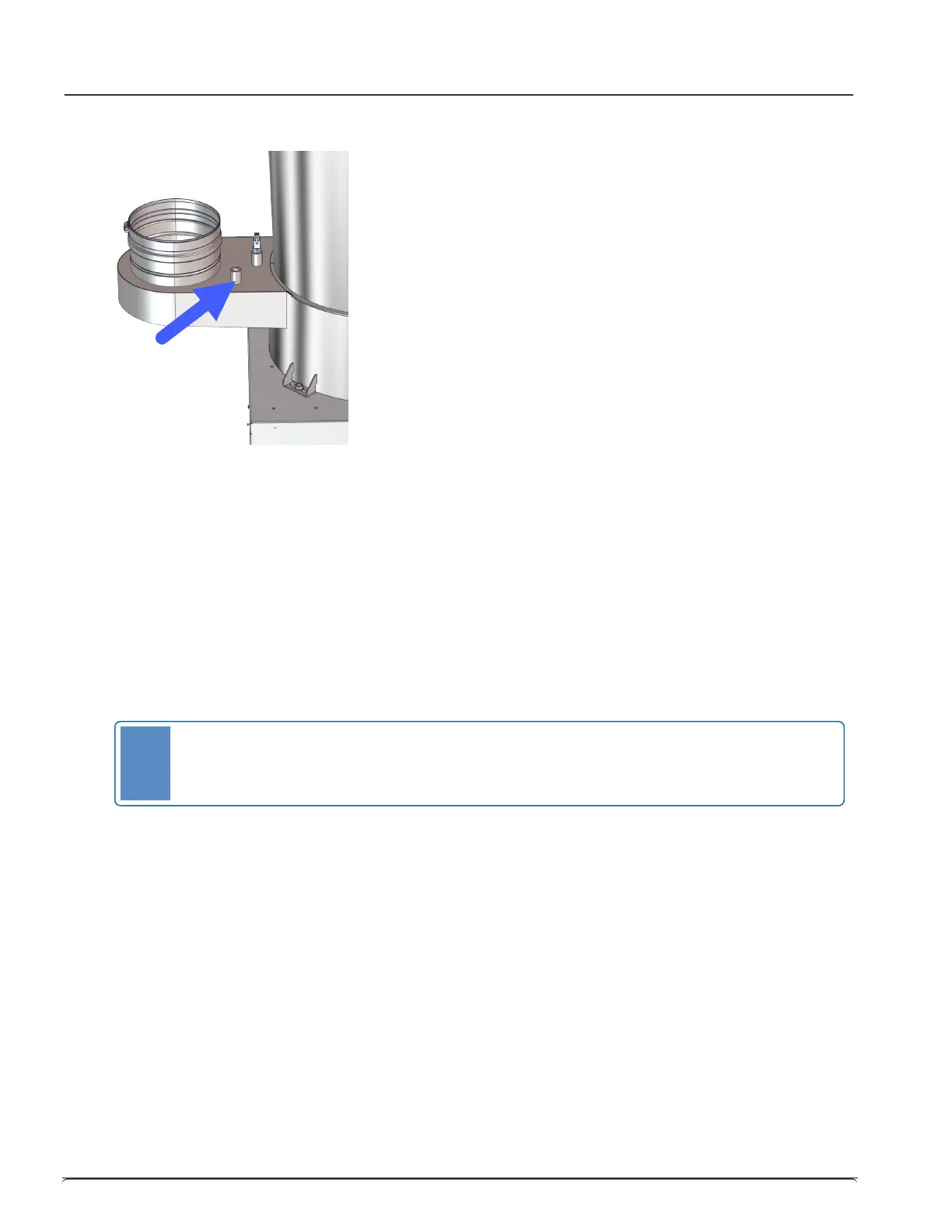

Figure2Flue gas test port

2. Settheheat-outvalueinmanualmodetotheminimumMBHfortheboiler(seeTable 1 ).

3. Lowfireadjustment-adjustthelowfireaccordingtoTable 2 .Usea2.5mmAllenkey.Turncounter-clockwise(in

thedirectionofthe'+'sign)toraisetoraisetheCO

2

%(torichen).TurnclockwisetolowerCO

2

%.Startwith1/8ofa

turnuntilyouseetheanalyzermeasureachangethenonlymake1/16adjustments.Ifchangingdirectiononthis

adjustmentyouwillnoticeasignificantbacklash(requirementfor1/8turnsuntilyouseetheanalyzermeasurea

change.

4.

Runtheboilertohighfire,andchecktheresultstoconfirmcorrectsettings.

Note

Clockthegasmetertoconfirmfullmaximumratingplateinput.CheckthemeasuredresultswithTable 1

.

5. Runtheboilertolowfire,andchecktheresultstoconfirmcorrectsettings.

6. Restoretheloadtothepreviousloadtype.Unlessyouchangedtheloadhighlimit,alltheprogrammedsettingswill

berestoredandtheloadwilloperateasbefore.Confirmasmoothignitionsequence.

7. Turnoffthegassupplyattheexternalgasshut-offvalve.

8. Disconnectthepowertotheboiler.

9. Removetheanalyzerprobeandinstallthetestportplug.

10. Disconnectthemanometer.

11. Removetheadapterfittingandreinstallthetestportplug.Keep the fitting with the boiler for future use.

12. Turnonthegassupplyshutoffvalveandtestforgasleaks.

13. Restorepowertotheboileraftertheconversioniscompleted.

Loading...

Loading...