15

OPERATING INSTRUCTIONS

V-10 TOUCH SCREEN BOILER CONTROLLER

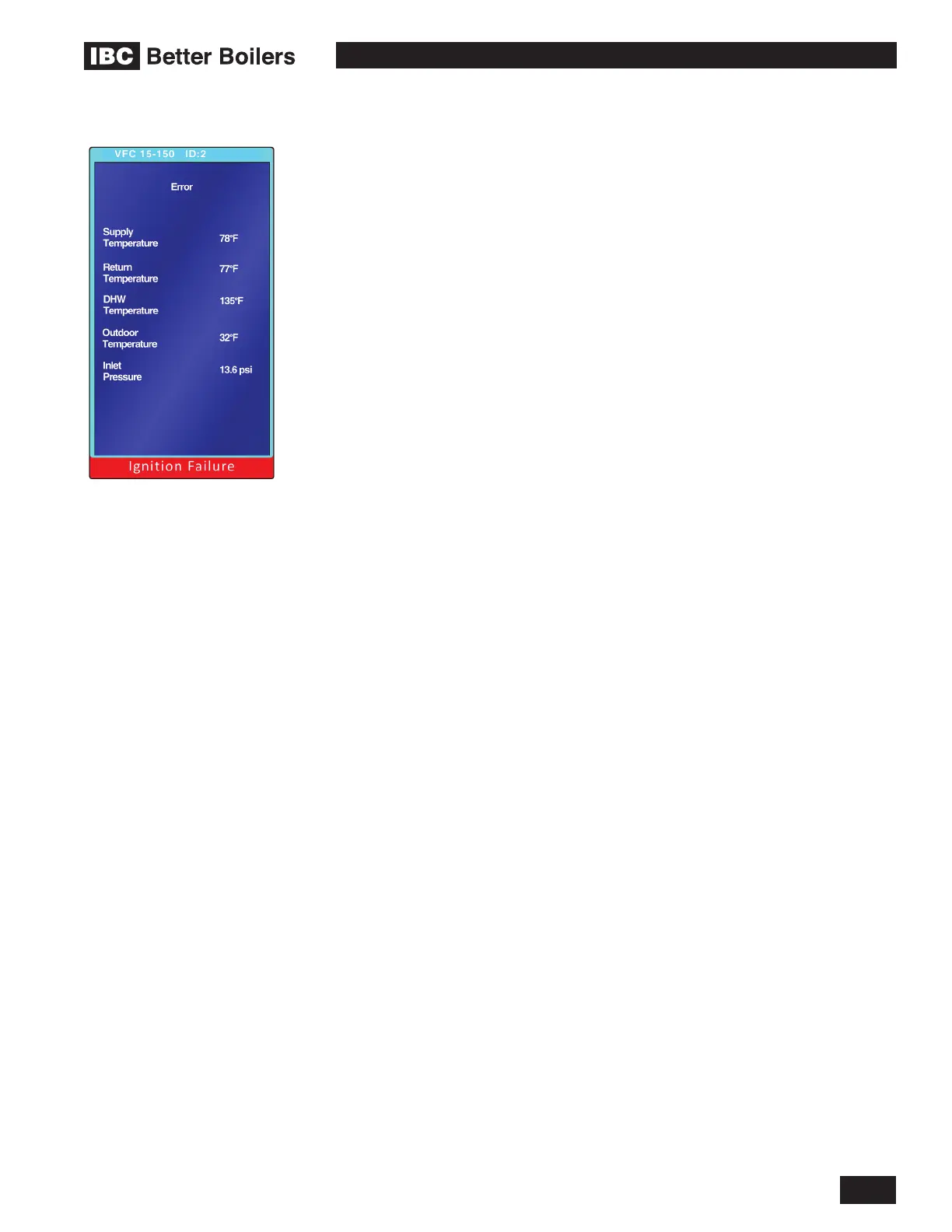

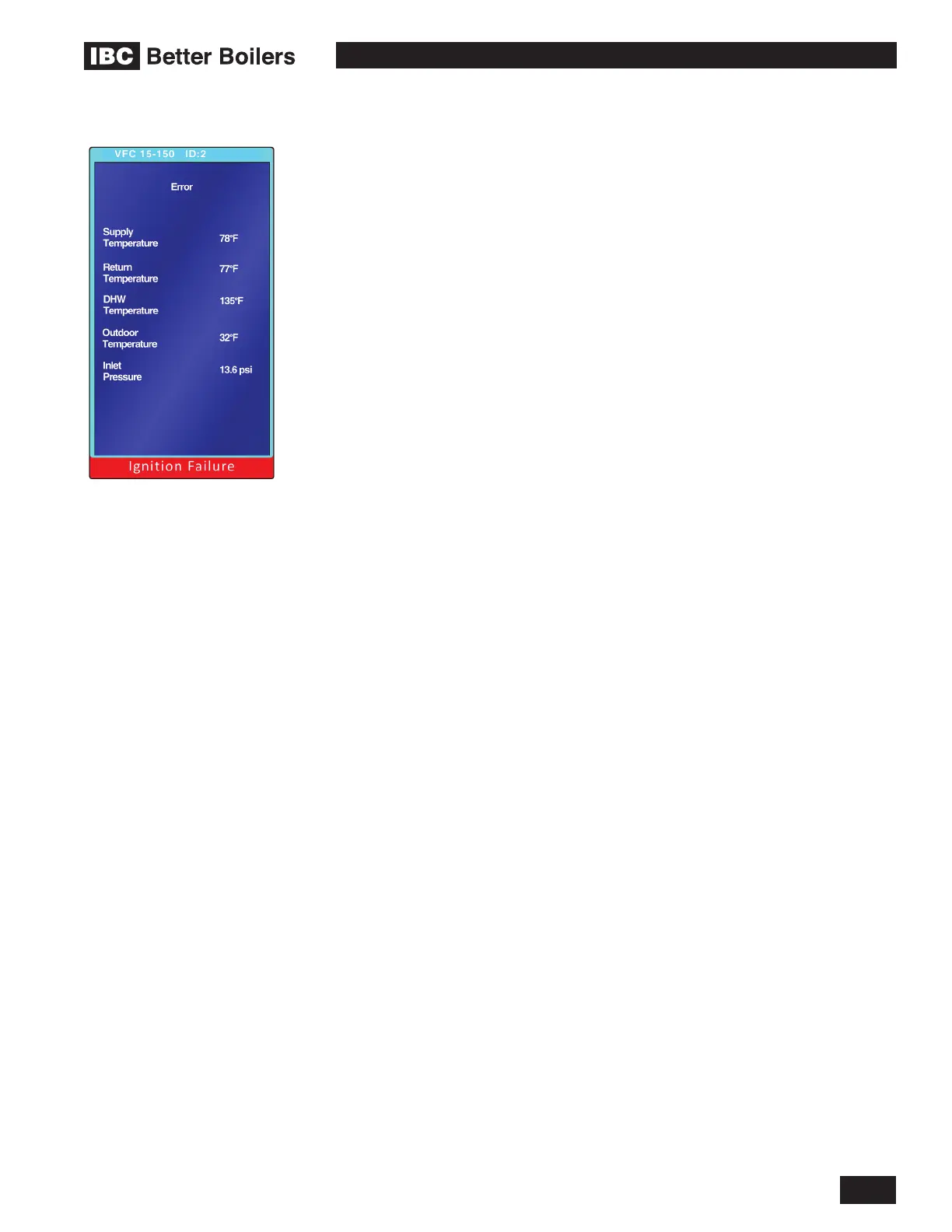

1.6.6 Error Code

The controller continually checks sensors to see that they are operating within

normal parameters. If sensors indicate the boiler is operating outside it limits, it

will declare an error condition.

Two types of error conditions can occur:

• Minor Errors: result when an abnormal condition exists which does not

present an immediate safety hazard. The boiler shuts off the fuel and enters

an extended purge, followed by the error cycle of 5 minutes for all conditions

other than maximum ignition trials (a modied Major error which locks out for

1 hour after 3 unsuccessful ignition attempts). Following the purge, the fan

and pump are stopped until the end of the error cycle. Normal operation then

resumes.

• Major Errors: result when a condition exists that may be a safety hazard.

The boiler enters an extended purge then the fan and pump are stopped.

The boiler is in a lockout, and must be checked and restarted by a service

technician.

See the Troubleshooting section 5.3.1 of the boiler’s Installation and Operating

Instructions for a list of errors and their likely causes. Note that other problems

such as disconnected wires or defective sensors may be the cause of the error.

Always check connections and wiring rst.

OTHER OPERATING FEATURES

1.7.1 Priority

The control module hosts a scheduling routine to manage the boiler’s operation

when more than one load has been dened. Typically, loads declared as DHW

receive signicant - but not absolute - priority. Multiple heating loads - with varying

temperature targets - are run sequentially as opposed to simultaneously (with

a mixing valve). The objective is to serve each load at the minimum possible

temperature, as opposed to running hot then mixing down – with hardware, saving

the related hardware and fuel cost. The approach optimizes the low temperature

combustion benets of direct cool running of a radiant oor. The large throttle

turndown range coupled with outdoor reset means that several loads can receive

heat in-turn, with less on/ off duty cycling than would occur with other heat sources.

The boiler is shipped with default values for each type of declarable load (e.g.

DHW, radiant oor). The preset variables for DHW (a value of 85-87 on a 20-

90 scale) give it substantial priority, which declines over time if another load is

calling. Spacing heating loads (with Outdoor Reset) are given default values

starting at a low of 28, while other Set Point loads start with 62. Over time, such

points are transferred between the loads in accordance with the system rules.

The boiler will automatically shift between loads once the points totals reach an

upset value. Upon a load transfer, the burner will modulate down to its base level

and will then throttle up as required for the new load. If competing loads have not

been satised at the load switch stage, the control will register the ring rate and

will return rapidly to such rate on the next rotation.

1.7

Loading...

Loading...