INSTALLATION AND OPERATION INSTRUCTIONS

1-6

VFC 15-150, VFC 45-225 MODULATING GAS BOILERS

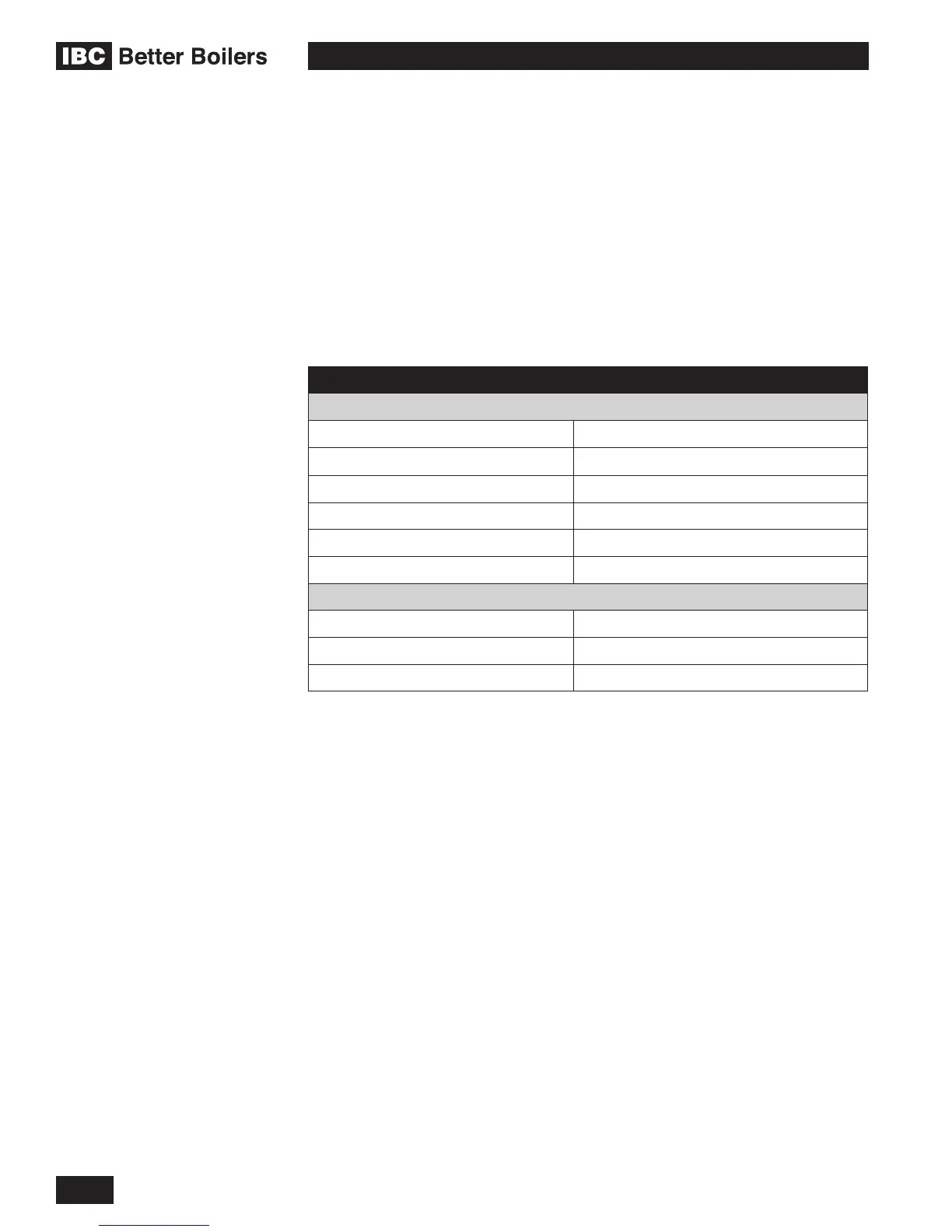

1.4.3 Vent Travel

CPVC or PPs (Rigid Single Wall) piping is the standard venting option; with

this, the VFC 15-150 boiler, for example, can be sited up to 50 equivalent feet

from the vent termination using 2” or up to 120’ using 3”. The actual vent travel

allowance is reduced for ttings in accordance with Table 4. – e.g. for an VFC

15-150 using 6 x 90º CPVC elbows, the maximum lineal measure of pipe allowed

using 3” pipe is 72 feet (120’ – (6 x 8’ = 48) = 72’).

For 3” exible PPs, up to 60 actual lineal feet are allowed in a nominally vertical

orientation (>45°). The equivalent length of 3” ex PPs shall be computed using

a multiple of 3:1, eg. 45’ x 3 = 135’ equivalent (for the VFC 45-225). With 45’ of 3”

ex, up to 105’ equivalent of 3” rigid PPs would still be allowed. 2” exible PPs is

not allowed.

EXHAUST PIPE SIZE MAXIMUM EQUIVALENT LENGTH

Sched.40; Rigid PPs

2" (15-150 only) 50' (each side)

3" (15-150) 120'

3" (45-225) 240'

90° vent elbow allow 8' equivalent

45° elbow allow 3’ equivalent

PPs 87-90° elbow allow 8’ equivalent

Flexible PPs

2” Flexible N/A

3” Flexible (VFC 15-150) 60’ (max) actual lineal x 1.5 = equivalent

3” Flexible (VFC 45-225) 60’ (max) actual lineal x 3 = equivalent

Table 4: Maximum exhaust venting length

Note: Unused intake travel cannot be added to the exhaust. Unequal intake

and exhaust piping is allowed (see Section 1.4.8).

Exhaust venting must slope down towards the boiler with a pitch of at least 1/4”

per foot (PPs vent: follow PPs manufacturer requirements) so condensate runs

back towards the trap. Support should be provided for intake and vent piping,

particularly so for horizontal runs (follow local code). Insulate exhaust piping

where it passes through unheated spaces or underground, with appropriate pipe

insulation to prevent freezing of condensates.

Certain installations of the VFC 15-150 model can employ the 2” vent options. We

caution installers when using horizontal runs of 2” pipe. Reason: air friction from the

fast moving exhaust during long burner runs at high-re in a 2” pipe can overcome

gravity on 1/4” / foot vent slope – leaving a pool of condensate at the next upturned

elbow. Pooling can impair the achievement of full high-re rating plate performance

.

If the site requires a horizontal exit immediately below the boiler – bush out to

3" pipe in the downward vertical run immediately below the 2" threaded adaptor,

and elbow to horizontal before splicing in a eld sourced 3" reducing tee for

mounting of the condensate trap; this will slow the exhaust velocity sufciently for

good drainage and reduce “spitting” at the vent termination. In this case, the 3" x

3/4" reducing tee would replace the 2" tee and 2" x 3/4" bushing supplied with the

VFC 15-150 boiler.

Loading...

Loading...