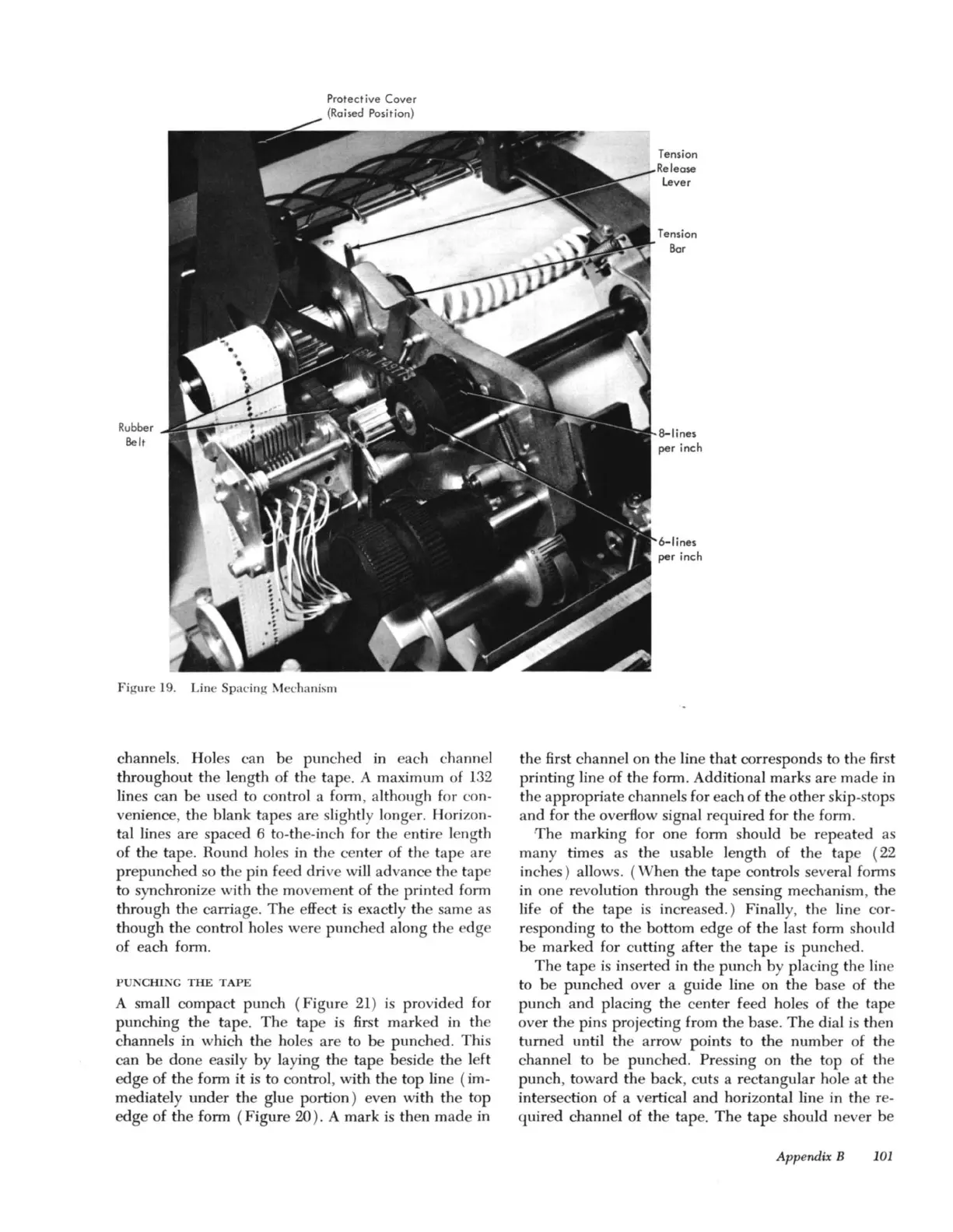

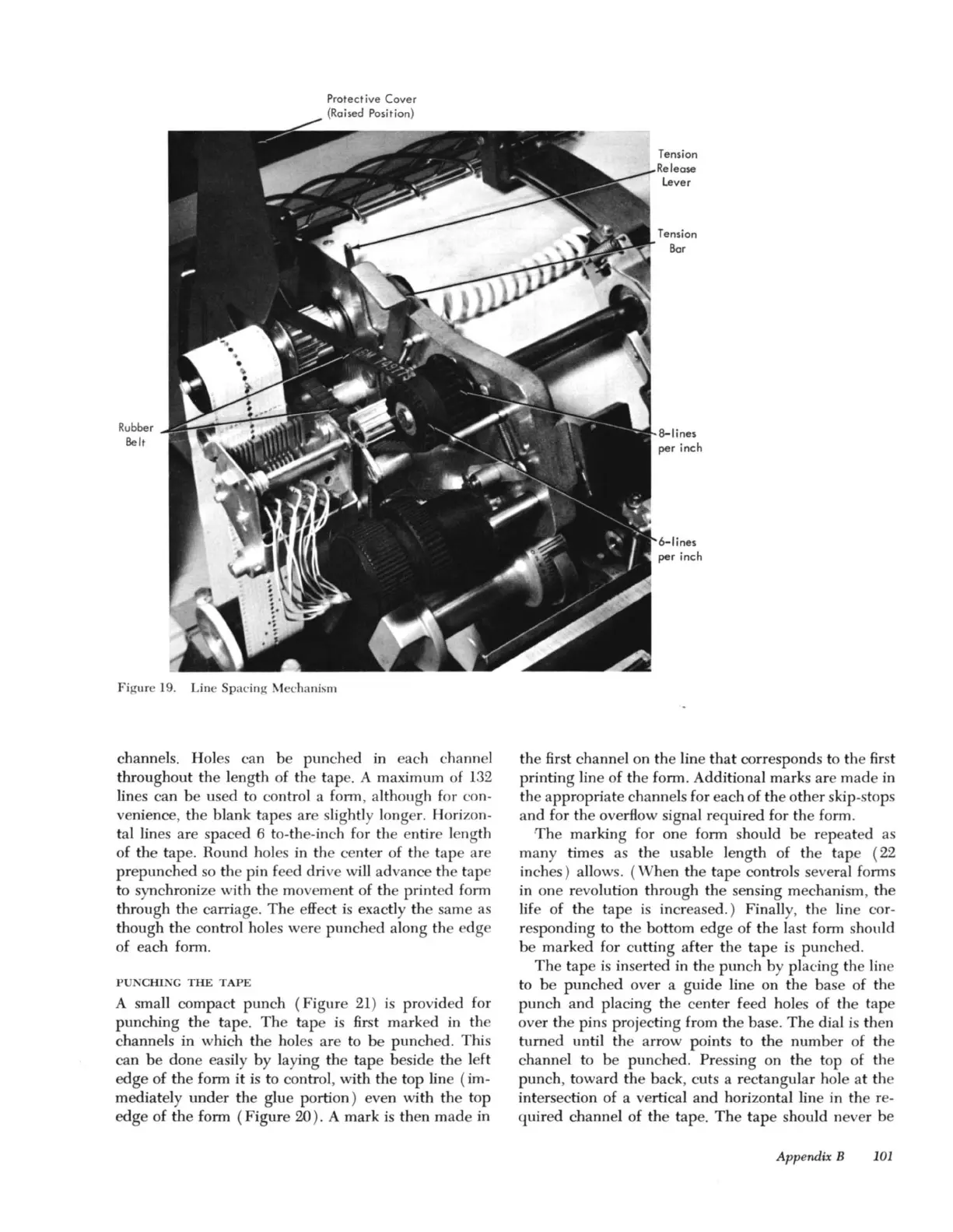

Rubber

Belt

Pro

tec

tive

Cover

(R

oised P

osition)

Figur

e 19. Line Spacing Mechanism

channel

s.

Hol

es

can be punched in each cha

nn

el

throughout the length of the tape. A maxjmum of 132

lines can be used to

co

ntrol a fo

rm

, although for

co

n-

venience, the blank tap

es

are s

li

ghtly longer. Ho

ri

zon-

tal lin

es

are spaced 6 t

o-

the-

in

ch for the entire length

of the tape. Round hol

es

in

the center of the tape are

pr

epunched

so

the pin feed dri

ve

will advance the tape

to synchronize with the movement of the printed form

through the carriage. The

eHect is exactly the same as

though

th

e control hol

es

were punched along the edge

of each form .

PU

CH

IN

G

THE

TA

PE

A small compact punch

(F

igure

21

) js

pr

ovided for

punching the tap

e.

The tape is

fir

st marked

in

the

channe

ls

in wruch the hol

es

are to be punched. Thjs

can be done ea

sil

y by laying the tape beside the left

edge of

the

form it

is

to control, with

the

top line (

im

-

mediately under the glue portion) even with the top

edge of the form

(Figur

e

20

). A mark

is

then made in

the

first channel

on

the line

that

corresponds to the

fir

st

printing line of the form. Additional marks

ar

e made in

the appropriate channels for each of the other skip

-s

tops

and for the ove

rfl

ow Signal required for the fo

rm

.

Th

e marking for one form should be repeated as

many times as the usable length of the tape (

22

in

ches) a

ll

ows. (

Wh

en the tape controls several forms

in one r

ev

olution through the sensing mecha

ni

sm, the

life of the tape is increased.) Finally, the line cor-

r

es

ponding to the bottom edge of the last fo

rm

should

be marked for cutting after the tape is punched.

Th

e tape is in

se

rted

in

the punch by placing the

li

ne

to be punched over a guide line on the base of the

punch and placing the ce

nt

er feed holes of the tape

over the pins

pr

ojecting from the bas

e.

The

di

al

is

then

turned until the arrow points to the number of the

channel to be punched.

Pr

es

sing on the top of the

punch, toward the back, cuts a rectang

ul

ar hole at the

intersection of a vertical and horizontal line in the r

e-

qUired channel of the tap

e.

The tape should never be

Appe

ndi

x B

101

Loading...

Loading...