(

c c

S T

1 1

4 4

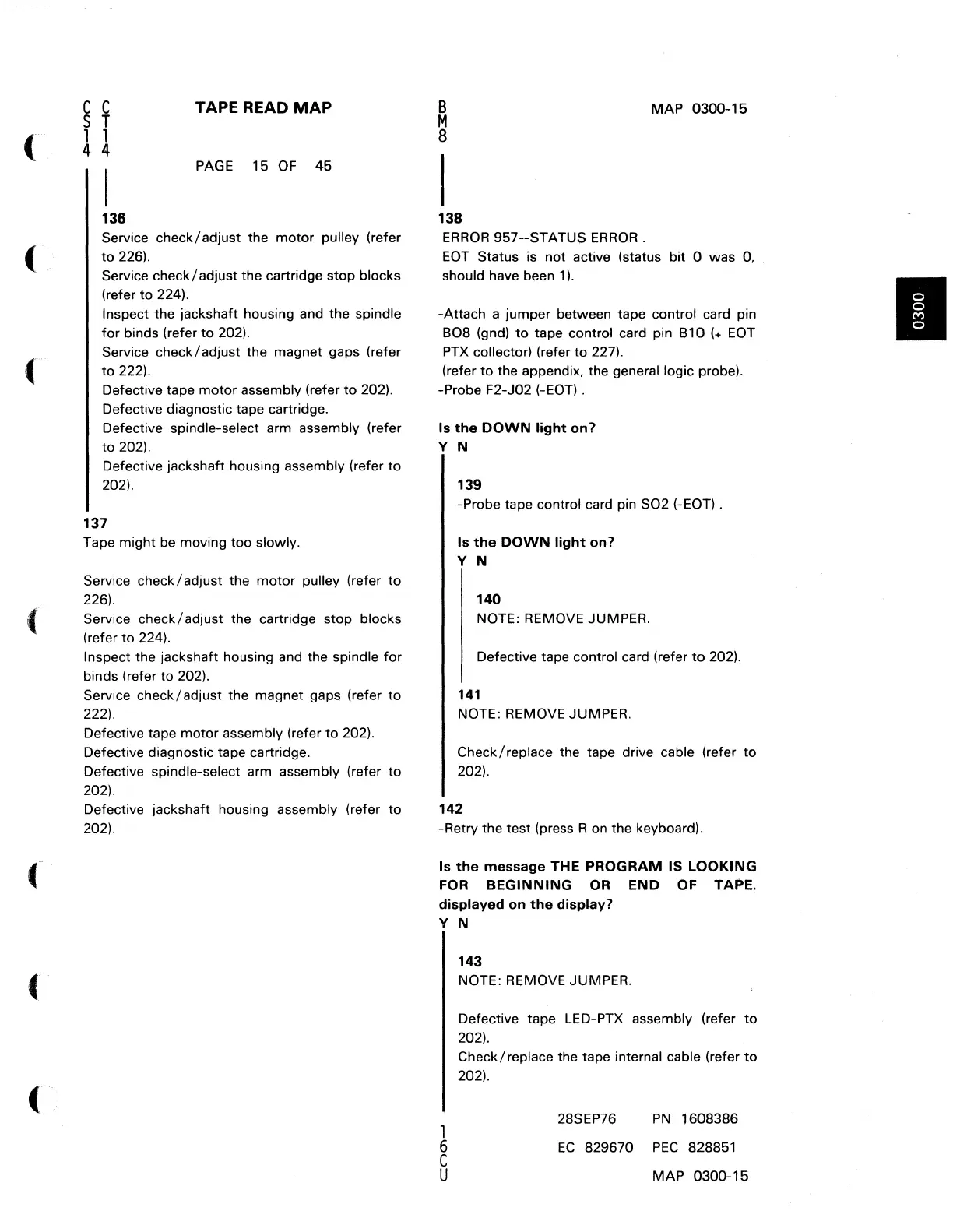

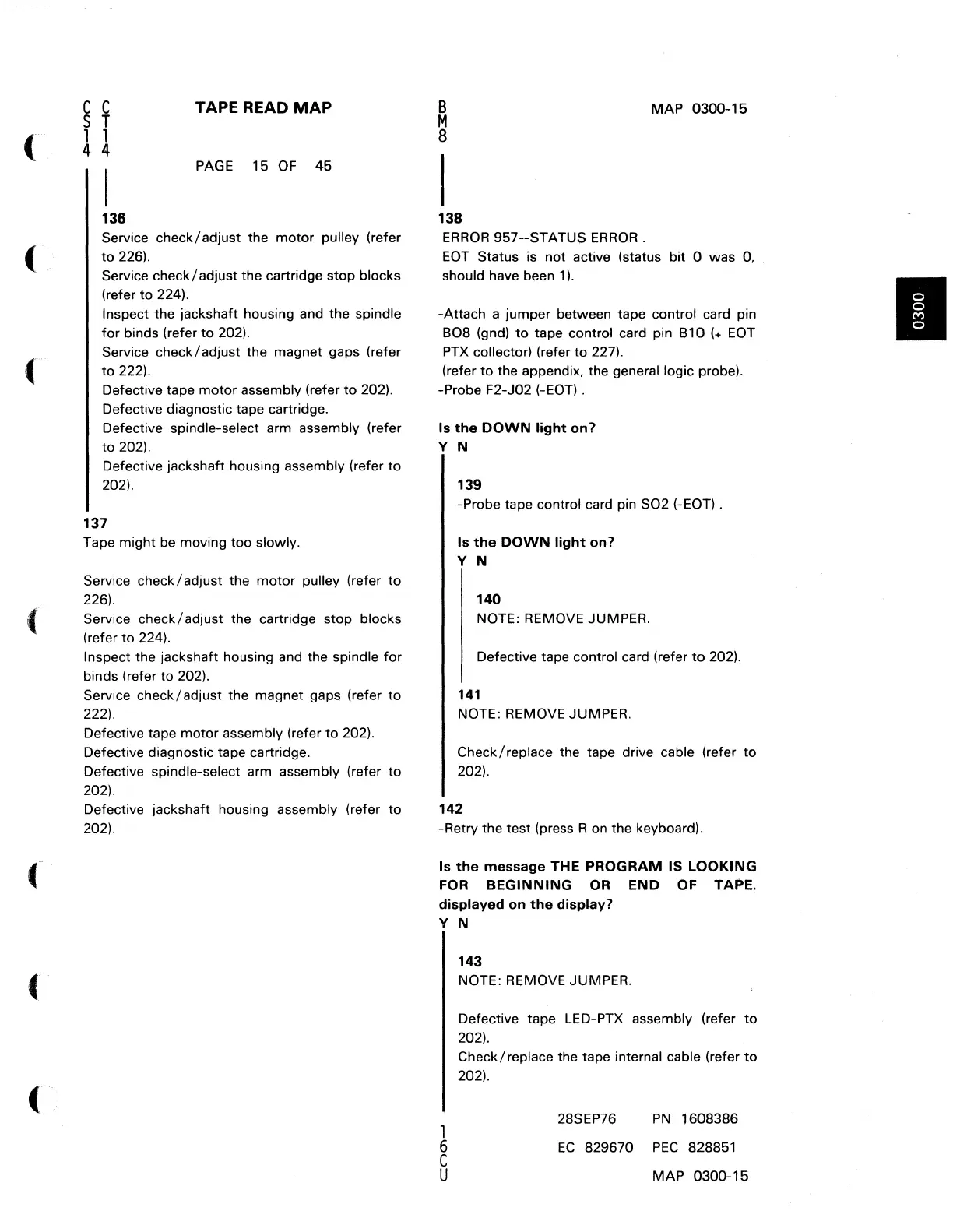

136

TAPE READ

MAP

PAGE

15

OF

45

Service

check/adjust

the

motor

pulley (refer

to

226).

Service

check/adjust

the cartridge

stop

blocks

(refer

to

224).

Inspect the jackshaft housing and the spindle

for

binds (refer

to

202).

Service

check/adjust

the magnet gaps (refer

to

222).

Defective tape

motor

assembly (refer

to

202).

Defective diagnostic tape cartridge.

Defective spindle-select arm assembly (refer

to

202).

Defective jackshaft housing assembly (refer

to

202).

137

Tape

might

be moving

too

slowly.

Service

check/adjust

the

motor

pulley (refer

to

226).

Service

check/adjust

the cartridge stop blocks

(refer

to

224).

Inspect the jackshaft housing and the spindle

for

binds (refer

to

202).

Service

check/adjust

the magnet gaps (refer

to

222).

Defective tape

motor

assembly (refer

to

202).

Defective diagnostic tape cartridge.

Defective spindle-select arm assembly (refer

to

202).

Defective jackshaft housing assembly (refer

to

202).

B

M

8

MAP

0300-15

138

ERROR

957--STATUS

ERROR.

EOT Status is

not

active (status

bit

0

was

0,

should have been

1).

-Attach

a

jumper

between tape control card pin

B08

(gnd)

to

tape control card pin

B10

(+

EOT

PTX collector) (refer

to

227).

(refer

to

the appendix, the general logic probe).

-Probe F2-J02 (-EOT) .

Is

the

DOWN

light

on?

Y N

139

-Probe tape control card pin

S02

(-EOT) .

Is

the

DOWN

light

on?

Y N

140

NOTE: REMOVE JUMPER.

Defective tape control card (refer

to

202).

141

NOTE: REMOVE JUMPER.

Check/replace

the tape drive cable (refer

to

202).

142

-Retry the

test

(press R on the keyboard).

Is

the

message

THE

PROGRAM

IS

LOOKING

FOR

BEGINNING

OR

END

OF TAPE.

displayed

on

the

display?

Y N

1

6

C

U

143

NOTE: REMOVE JUMPER.

Defective

tape

LED-PTX assembly (refer

to

202).

Check/replace

the tape internal cable (refer

to

202).

28SEP76

PN

1608386

EC

829670

PEC

828851

MAP

0300-15

Loading...

Loading...