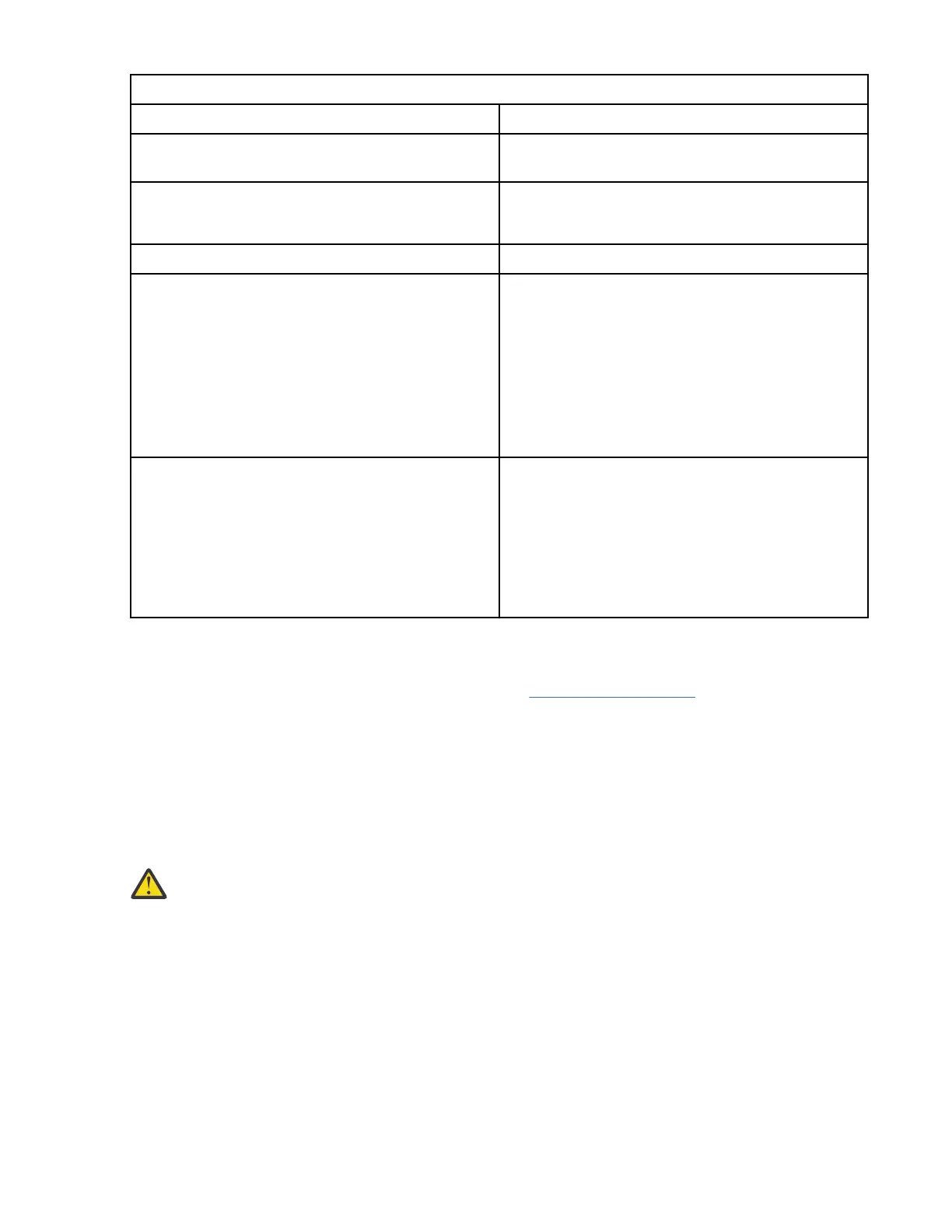

Table 4. Heat exchanger water specications

Water Specications

Source User-supplied, compliant with specications in this

document

Pressure Normal operation: <137.93 kPa (20 psi)

Maximum: 455 kPa (66 psi)

Volume Approximately 9 liters (2.4 gallons)

Temperature Above dew point

18°C ±1°C (64.4°F ±1.8°F) for ASHRAE Class 1

Environment

22°C ±1°C (71.6°F ±1.8°F) for ASHRAE Class 2

Environment

Note: See “Heat exchanger performance” for more

information.

Required water flow rate (as measured at the

supply entrance to the heat exchanger)

The flow rate of the water in the system must be in

the range of 23 - 57 liters (6 - 15 gallons) per

minute.

Pressure drop versus flow rate for heat exchangers

(including quick-connect couplings) is dened as

approximately 34 kPa ( 5 psi) at 57 liters (15

gallons) per minute.

Heat exchanger performance

Select the correct water inlet temperature and water flow rate to achieve the necessary heat removal.

Expected performance of the heat exchanger is shown in Figure 102 on page 145 for a typical inlet air

temperature of 27°C (80.6°F), with a fully populated rack, near uniform power dissipation, and a 30 kW

heat load.

A heat removal of 100% indicates that an amount of heat equivalent to that generated by the devices has

been removed by the heat exchanger and the average air temperature leaving the heat exchanger is

identical to that entering the rack (27°C [80.6°F] in this example). Heat removal in excess of 100%

indicates that the heat exchanger not only removed all of the heat generated by the devices but further

cooled the air so that the average air temperature leaving the rack is actually lower than that entering the

rack.

Attention:

To help maintain optimum performance of the rear door heat exchanger and provide proper

cooling for all rack components, you must always take the following precautions:

1. Install ller panels over all unoccupied bays.

2. Route signal cables at the rear of the rack so that they enter or exit the cabinet through the top

and bottom air baffles.

3. Bundle signal cables together in a rectangle so that the upper and lower air-baffle sliders are

closed as far as possible. Do not bundle signal cables together in a circular formation.

The following illustration shows the typical performance of the heat exchanger, 30kW heat load.

144

Power Systems: Racks and rack features

Loading...

Loading...