16 17

Maintenance / RemovalTechnical specications

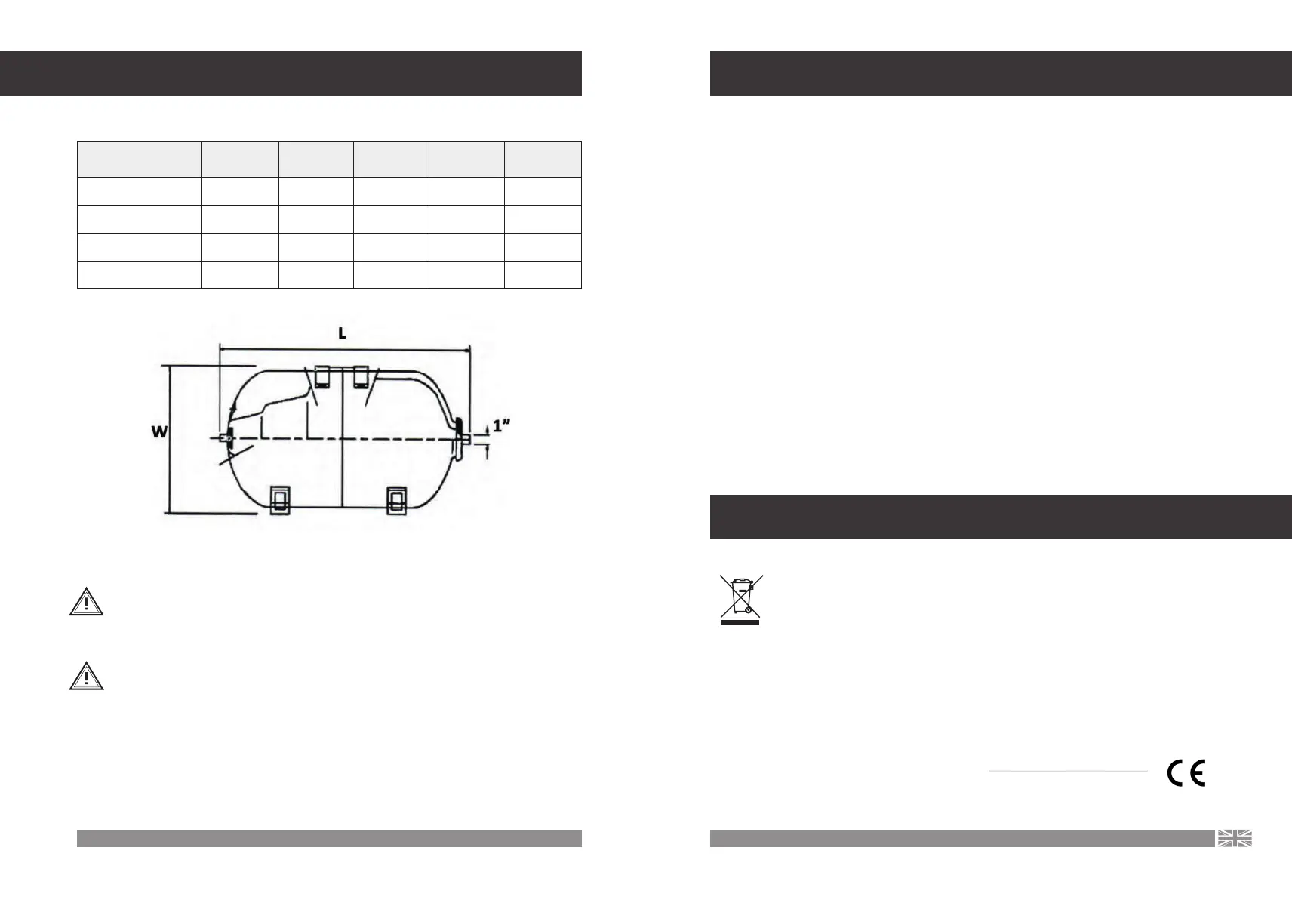

Table No. 1

Maintenance activities may only be carried out by qualied and licensed personnel after

reading the operating instructions. Maintenance activities should be carried out at least once

every three months. First of all, check the pre-pressure if it is within the range given by the

manufacturer if not, adjust the pressure. Before carrying out any maintenance, shut down

the installation and wait until the temperature of the refrigerant guaranteeing safe operation

is lowered. It is necessary to remember that before controlling the air pressure, shut o the

ow of the heating medium to the vessel and after reducing the pressure of the heating

agent in the vessel, you can check the air pressure level. Without reducing the pressure of

the heating medium in the vessel, the air pressure will either indicate the pressure of the

heating medium in the system or if the airbag runs out, it will indicate zero.lf any damage to

the outer coating is visible: cracks, corrosion, deformation or if the diaphragm rupture has

been suspected, replace the vessel with new ones. The water quality in the system should

be checked, the quality of the water aects pot life.

REMOVAL

Before starting the disassembly work, turn o the installation and wait until the temperature

of the factor guaranteeing safe service is lowered. Then, safely reduce the system pressure

and the container to zero.

The DAMBAT company is not responsible for damage to the device, property or personal in-

jury as a result of not following the instructions contained in the manual, including incorrect

selection of the device, assembly not compliant with the instructions, applicable standards

and national regulations, improper maintenance of the device and the entire system.

Disposing of the device

The used product is subject to disposal as wastes only in selective waste

collection systems organised by the Network of Communal Electric and Elec-

tronic Waste Collection Centres. The customer is entitled to return the used

equipment to the network of the electric equipment distributor, at least for

free and directly, if the returned device is of proper type and fulls the same

function as a newly purchased device.

It is prohibited to dispose of electric equipment together with other household waste.

The year the device was marked with the CE mark

(entered by the seller on the basis of the nameplate)

Model

Working

temperature

Max. tested

pressure PT

Working

volume

Precharge

pressure

Dimension

W/L

PRESSURE VESSEL

TYP 24

0-70°C

8 bar 19,1 dm 1,7bar +/- 10% 28,7

×

42,5 cm

PRESSURE VESSEL

TYP 50

0-70°C

8 bar 40,5 dm 1,7bar +/- 10% 3 8

×

52 cm

PRESSURE VESSEL

TYP 80

0-70°C

8 bar 76,0 dm 1,7bar +/- 10% 48

×

61 cm

PRESSURE VESSEL

TYP 100

0-70°C

8 bar 82,5 dm 1,7bar +/- 10% 64

×

48 cm

COMMENTS:

If the air pressure is lower or higher than the one given above, bring it to the correct

one (for example using a car pump or a compressor). The valve is used to inate or

drain the air from the tank - the valve is identical to the wheels of the car located in

the rear part of the tank.

The air pressure in the tank should be checked at least once every 3 months. If the

tank works as a hydrophore with a pump, the pressure check should be carried out

after switching o the hydrophore from the electrical network and draining the water

from the installation (unscrewing the tap).

The tanks of the INOX series are made of stainless steel AISI 304. The dimensions of the

tanks correspond to the tanks of the BLUE series. In connection with making both the

tank and the ange made of stainless steel, the tanks can be mounted in wet places

such as a well, keeping in mind the access to checking the pressure in the tank.

Loading...

Loading...