6. Removefourscrewsholdingtoppaneltocasing.Remove

toppanel.Discardtoppanel.Setscrewsaside.

7. Installdrafthoodassy.tocasingusingfourscrewspreviously

setaside.

8. Attachfieldconnectboxtodrafthoodassy.usingtwoscrews

previouslysetaside.

9. NTC5,NTN5&GNJSeriesfurnaces- Attachpressure

switchtodrafthoodassy.usingtwoscrewspreviouslyset

aside.

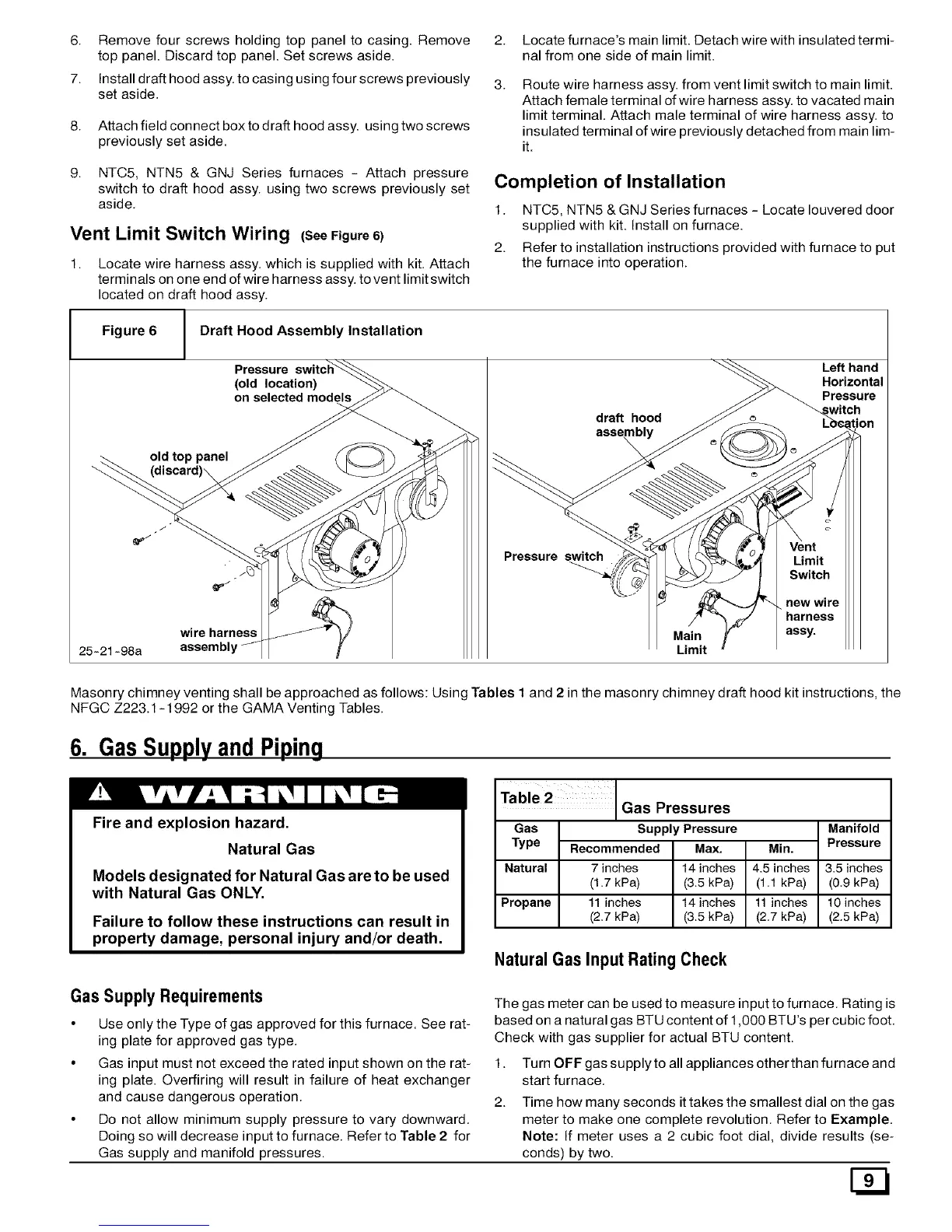

Vent Limit Switch Wiring (seeFigure6)

1. Locate wire harness assy. which is supplied with kit. Attach

terminals on one end of wire harness assy. to vent limit switch

located on draft hood assy.

2. Locate furnace's main limit. Detach wire with insulated termi-

nal from one side of main limit.

Route wire harness assy. from vent limit switch to main limit.

Attach female terminal of wire harness assy. to vacated main

limit terminal. Attach male terminal of wire harness assy. to

insulated terminal of wire previously detached from main lim-

it.

Completion of Installation

1. NTC5, NTN5 & GNJ Series furnaces - Locate Iouvered door

supplied with kit. Install on furnace.

2. Refer to installation instructions provided with furnace to put

the furnace into operation.

Figure 6 Draft Hood Assembly Installation

old top panel

(discard)\

Pressure

(old location)

on selected models

draft hood

assembl

Left hand

Horizontal

Pressure

J

Vent

Pressure switch Limit

Switch

new wire

harness

wire harness Main assy.

25-21-98a assembly Limit

Masonry chimney venting shall be approached as follows: Using Tables I and 2 in the masonry chimney draft hood kit instructions, the

NFGC Z223.1-1992 or the GAMA Venting Tables.

6. GasSupplyand Piping

Fire and explosion hazard.

Natural Gas

Models designated for Natural Gas are to be used

with Natural Gas ONLY.

Failure to follow these instructions can result in

property damage, personal injury and/or death.

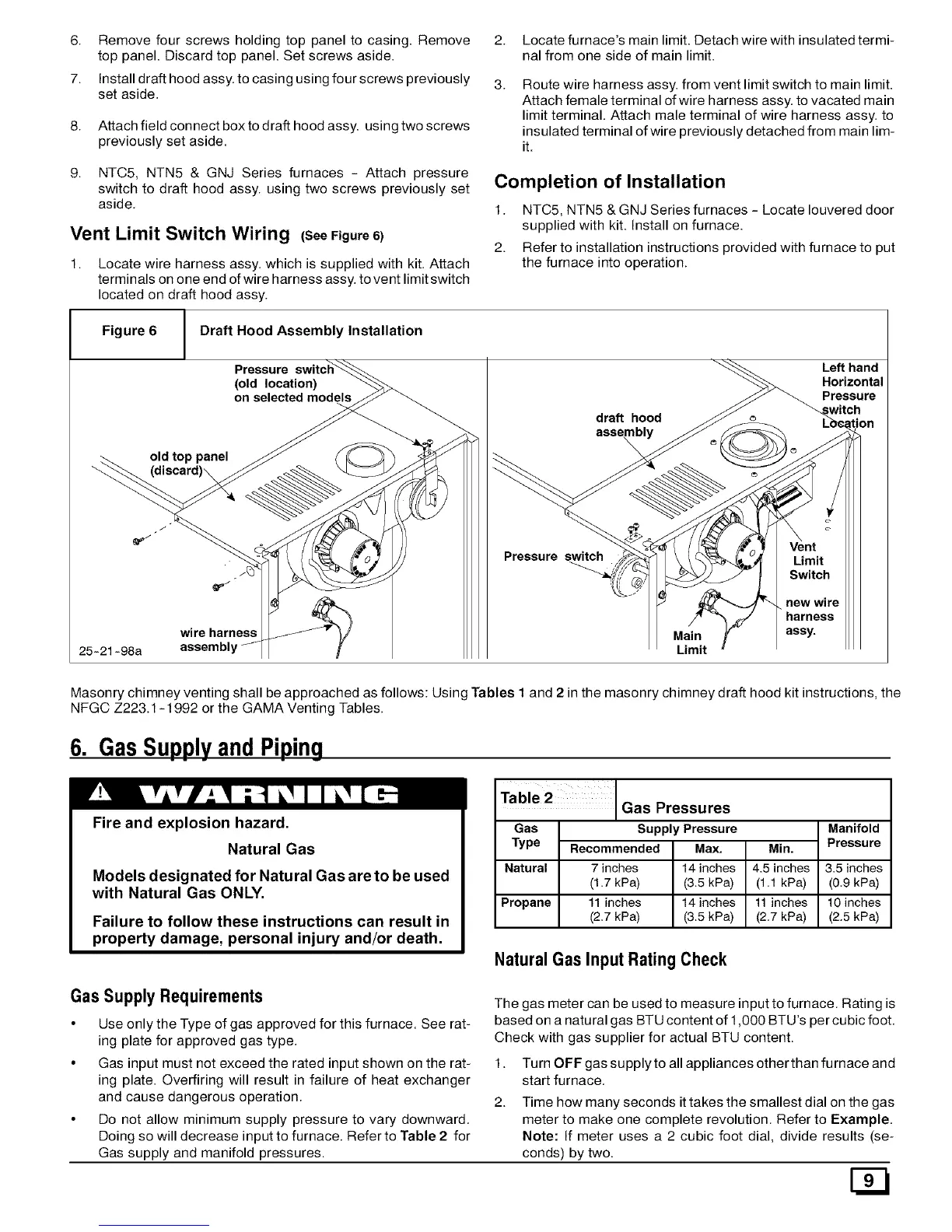

Table 2

Gas

Type

Manifold

Pressure

Gas Pressures

supply Pressure

Recommended Max.

7 inches 14 inches

(1.7 kPa) (3.5kPa)

11 inches 14 inches

(2.7 kPa) (3.5kPa)

Min.

Natural 4.5 inches 3.5 inches

(1.1 kPa) (0.9 kPa)

Propane 11 inches 10 inches

(2.7 kPa) (2.5 kPa)

Natural Gas InputRating Check

Gas Supply Requirements

• Use only the Type of gas approved for this furnace. See rat-

ing plate for approved gas type.

• Gas input must not exceed the rated input shown on the rat-

ing plate. Overfiring will result in failure of heat exchanger

and cause dangerous operation.

• Do not allow minimum supply pressure to vary downward.

Doing so will decrease input to furnace. Refer to Table 2 for

Gas supply and manifold pressures.

The gas meter can be used to measure input to furnace. Rating is

based on a natural gas BTU content of 1,000 BTU's per cubic foot.

Check with gas supplier for actual BTU content.

1. Turn OFF gas supply to all appliances otherthan furnace and

start furnace.

2. Time how many seconds it takes the smallest dial on the gas

meter to make one complete revolution. Refer to Example.

Note: If meter uses a 2 cubic foot dial, divide results (se-

conds) by two.

Loading...

Loading...