© 2019, Gast Manufacturing

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

6

Change output shaft direction of worm gear reducers

1. Remove drain plug and drain oil from unit.

2. Remove end cover and seal cage cap screws. While supporting

output shaft, remove end cover and shims from unit. Keep

shims with cover.

3. Remove output shaft and seal cage together from extension

side. Keep shims with seal cage.

4. Insert seal cage, shims and sub-assembly into housing from

the side opposite from which they were removed.

5. Insert seal cage cap screws and tighten with light pressure.

6. Assemble end cover with shims. Insert end cover cap screws

and tighten with light pressure.

7. Turn high speed shaft in both directions to check that gear train

is running freely.

8. Cross-tighten seal cage and end cover cap screws.

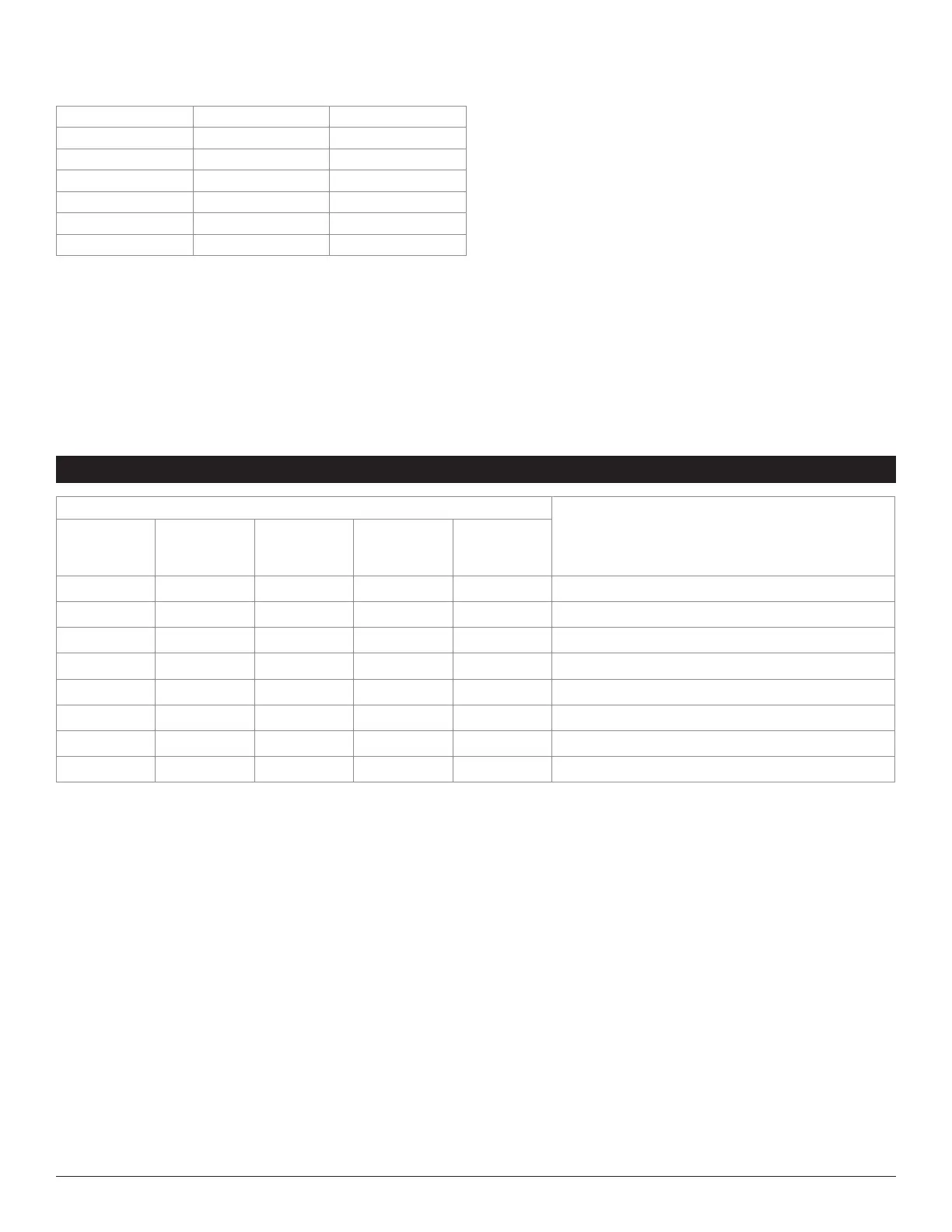

Worm Gear Reducer Series A-F

Gear Reducer Specifications

All output shafts are in the standard location.

Model Air Motor Ratio

AG803 4AM 20:1

AG805 4AM 40:1

AG807 4AM 60:1

AG809 6AM 10:1

AG811 6AM 20:1

AG816 8AM 20:1

Service, Parts, or Repair

For service, parts or repair of the worm gear reducer, contact the

manufacturer listed on the nameplate.

Part No. 45-200 D170PL (Rev. S)

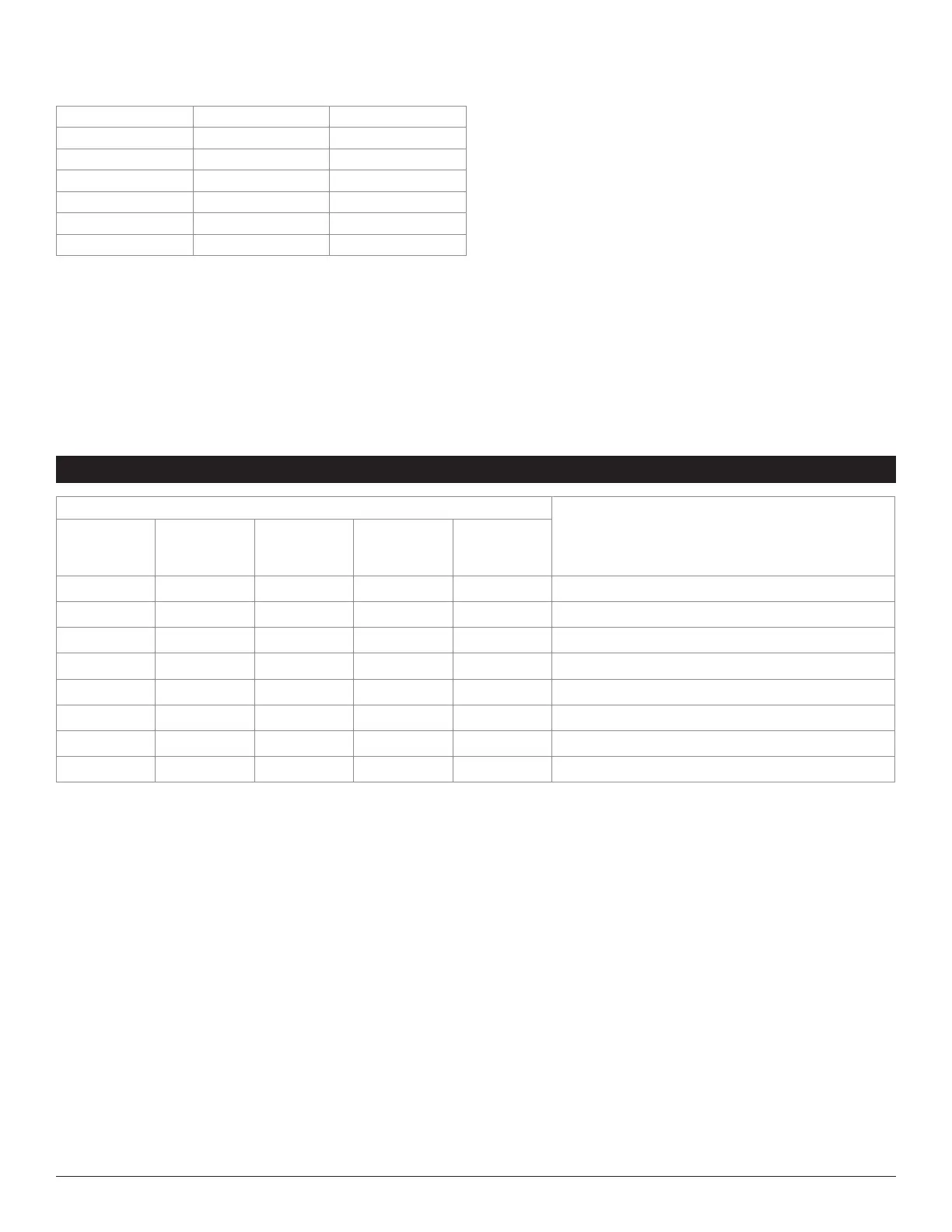

TROUBLESHOOTING GUIDE

Problem

Reason and Remedy for Problem

Low Torque Low Speed Won’t Run Runs Hot

Runs Well

Then Slows

Down

• • •

Dirt or foreign material present. Inspect and ush.

• • •

Internal rust. Inspect and ush.

• •

Low air pressure. Increase pressure.

•

Air line too small. Install larger line(s).

• •

Restricted exhaust. Inspect and repair.

• • • •

Motor is jammed. Have motor serviced.

• •

Air source inadequate. Inspect and repair.

• •

Air source too far from motor. Recongure setup.

Loading...

Loading...