Fan Coils

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

5

SECTIONONE—Receipt&InitialInstallation,Cont’d.

SalesRepresentativeshouldbenotiedimmediatelyso

thatproperactionmaybetaken.

NOTE: Shouldanyquestionsariseconcerningwarrantyrepairs,the

factorymustbenotiedBEFOREanycorrectiveactionistaken.

Wherelocalrepairsoralterationscanbeaccomplished,

thefactorymustbefullyinformedoftheextentand

expectedcostofthoserepairsbeforeworkisbegun.

Wherefactoryoperationsarerequired,thefactorymust

becontactedforauthorizationtoreturnequipmentanda

ReturnAuthorizationNumberwillbeissued.Unauthorized

returnshipmentsofequipmentandshipmentsnotmarked

withanauthorizationnumberwillberefused.Inaddition,

anyclaimsforunauthorizedexpenseswillnotbeaccepted

bythemanufacturer.

Handling and Installation

Whileallequipmentisdesignedandfabricatedwith

sturdymaterials,andmaypresentaruggedappearance,

greatcaremustbetakentoassurethatnoforceor

pressurebeappliedtothecoil,pipingordrainstub-

outsduringhandling.Also,dependingontheoptions

andaccessories,someunitscouldcontaindelicate

componentsthatmaybedamagedbyimproperhandling.

Whereverpossible,allunitsshouldbemaintainedinan

uprightposition,andhandledbythechassis,plenum

sections,orascloseaspossibletothemounting-point

locations.Inthecaseofafullcabinetunit,theunitmust

obviouslybehandledbytheexteriorcasing.Thisis

acceptableprovidingtheunitisagainmaintainedinan

uprightposition,andnoforceisappliedthatmaydamage

internalcomponentsorpaintedsurfaces.

TheequipmentcoveredinthismanualIS NOTsuitable

foroutdoorinstallations.Theequipmentshouldneverbe

storedorinstalledwhereitmaybesubjectedtoahostile

environmentsuchasrain,snow,orextremetemperatures.

Before,during,andafterinstallation,specialcaremustbe

takentopreventforeignmaterialsuchaspaint,plaster,

anddrywalldustfrombeingdepositedinthedrainpanor

onthemotororblowerwheels.Failuretodosomayhave

seriousadverseeffectsonunitoperation,andinthecaseof

themotorandblowerassembly,mayresultinimmediateor

prematurefailure.Allmanufacturer’swarrantiesarevoidif

foreignmaterialisallowedtobedepositedinthedrainpan

oronthemotororblowerwheelsofanyunit.Someunits

and/orjobconditionsmayrequiresomeformoftemporary

coveringduringconstruction.

Installation Instruction for Ceiling Hung Units

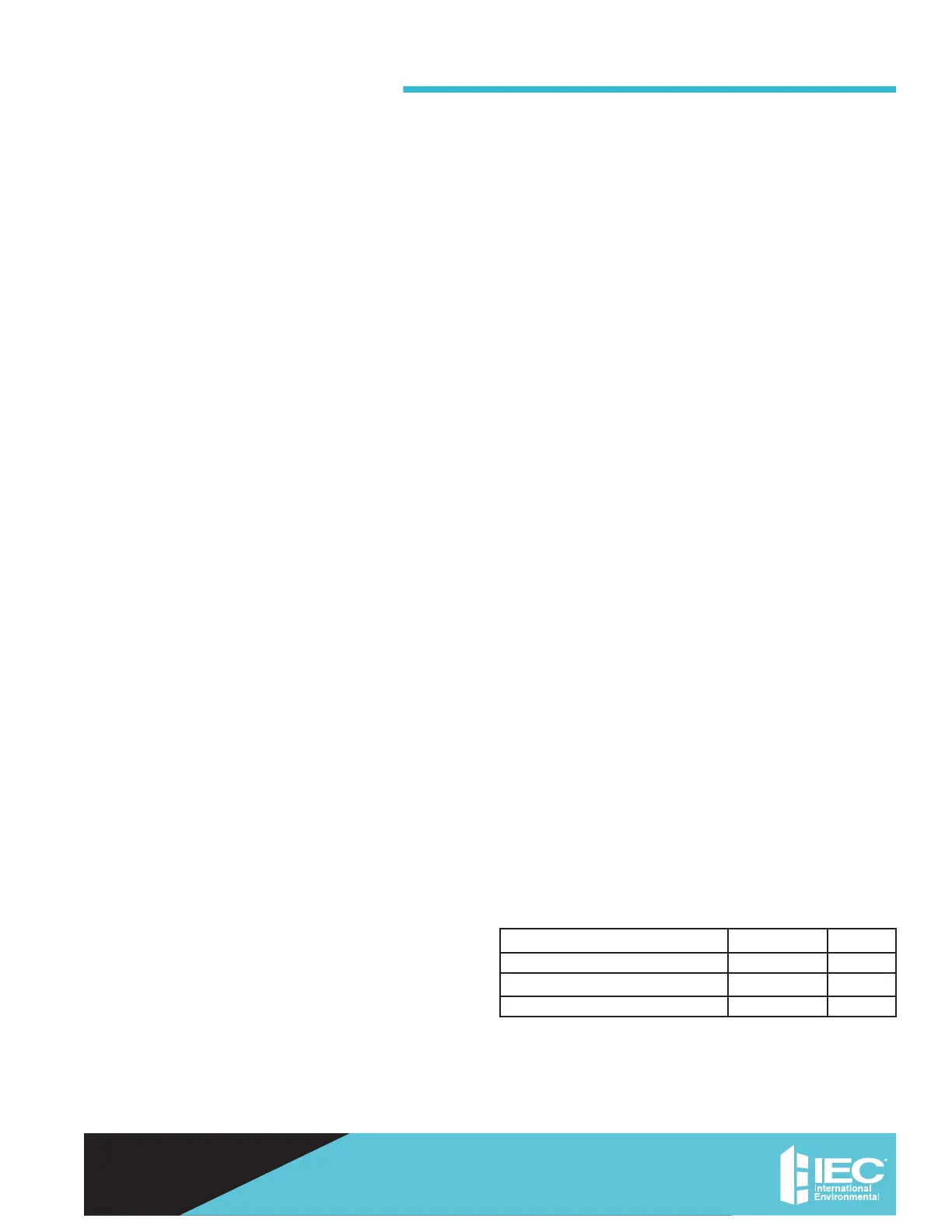

Anchoringtheequipmentinplaceisaccomplishedby

usingthemountingpointsprovidedwith3/8”or1/2”

allthread(notsuppliedwithunit).See Figure 1 for

recommended all-thread diameter.Theunitmustbe

positionedsothatthedrainpanisonaLEVELPLANE.

Caremustbetakentoinsurethatthedrainpandoesnot

slopawayfromtheoutletconnection.Horizontalopen

coilunitmodelsHHYorFHYmaybemountedusingthe

neoprenegrommetsprovided.Plenum-typeunitmodels

HPYorCPYmaybemountedusingthefourgrommetsin

thecoilsection,ortherearcoilsectiongrommetsmaybe

removedtotheplenumhangerbrackets.Hi-performance

cabinetunitmodelsHLYorHXYmustbemountedusing

theslottedhangerrailsprovided.(Grommetsarenot

furnishedfromthefactory).

Othereld-furnishedmountingdevicessuchasrubber-

in-shearorspring-typevibrationisolatorsselectedbythe

contractororengineermaybesubstitutedforthefactory

grommets,andshouldbeusedwherefactorygrommets

arenotprovided.

Itshouldbenotedthatunacceptablesystemoperating

characteristicsand/orperformancemayresultfrom

improperorinadequateunitstructuralsupport.Inaddition

adequateclearancemustbeprovidedforserviceand

removaloftheequipmentanditsaccessorycomponents.

Figure 1. Threaded Rod Recommendations

Model Rod Diameter Rod Qty

C*Y02,03,04,06,08,10,12 3/8” 4

H*Y06,08,10,12,14,16,18,20 3/8” 4

H*D06,08,10,12,16,20,30,40 1/2” 4

Loading...

Loading...