MAINTENANCE 9VX3

500 HOURS MAINTENANCE AND CHECKS

First perform previous service hour items

■ Check the Fixed Bolt Torque

When loosened bolt or nut is found at daily check, tighten it with

torque specifications table.

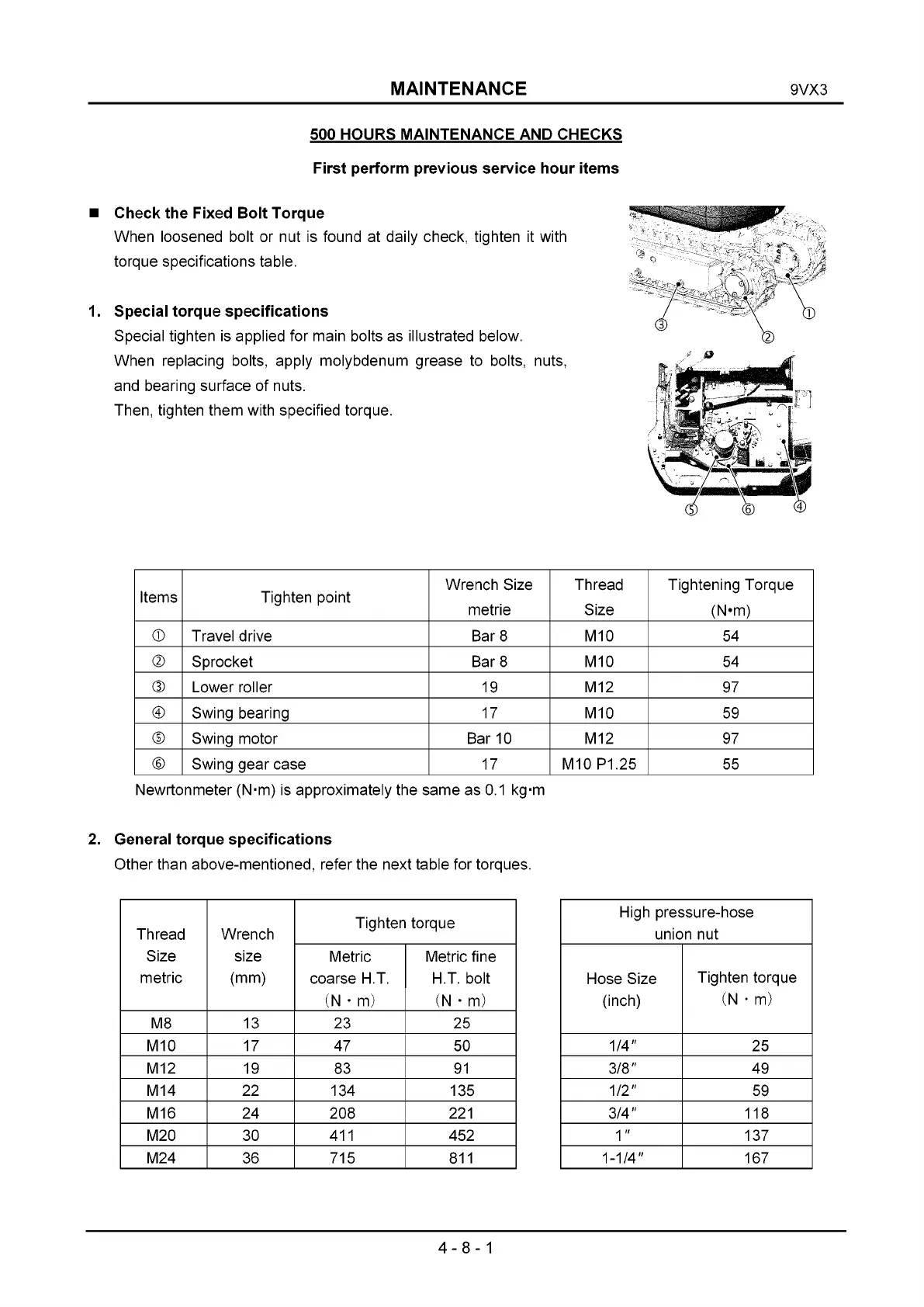

1. Special torque specifications

Special tighten is applied for main bolts as illustrated below.

When replacing bolts, apply molybdenum grease to bolts, nuts,

and bearing surface of nuts.

Then, tighten them with specified torque.

Items Tighten point

Wrench Size

metrie

Thread

Size

Tightening Torque

(N*m)

© Travel drive Bar 8 M10 54

© Sprocket Bar 8 M10 54

Lower roller

19

M12 97

©

Swing bearing 17

M10 59

© Swing motor Bar 10 M12 97

© Swing gear case 17 M10 P1.25 55

Newrtonmeter (N-m) is approximately the same as 0.1 kg-m

2. General torque specifications

Other than above-mentioned, refer the next table for torques.

Thread

Size

metric

Wrench

size

(mm)

Tighten torque

Metric

coarse H.T.

(N • m)

Metric fine

H.T. bolt

(N • m)

M8 13 23 25

M10 17 47 50

M12

19 83 91

M14 2 2 134

135

M16 24 208 221

M20 30 411 452

M24

36 715 811

High pressure-hose

union nut

Hose Size

Tighten torque

(inch)

(N • m)

1/4" 25

3/8" 49

1/2 "

59

3/4" 118

1 " 137

1-1/4" 167

4-8-1

Loading...

Loading...