MAINTENANCE 9VX3

WHEN REQUIRED MAINTENANCE AND CHECKS

TRACKS CHECK I ADJUST

AWARNING

1.

2.

* Grease is under high pressure.

* NEVER remove the grease fitting.

* Grease coming out of the check valve under pressure can

penetrate the body causing injury or death.

* DO NOT watch the check valve to see if grease is escaping.

Watch the track or track adjustment cylinder to see if the

track is being loosened.

* Loosen the check valve one turn only.

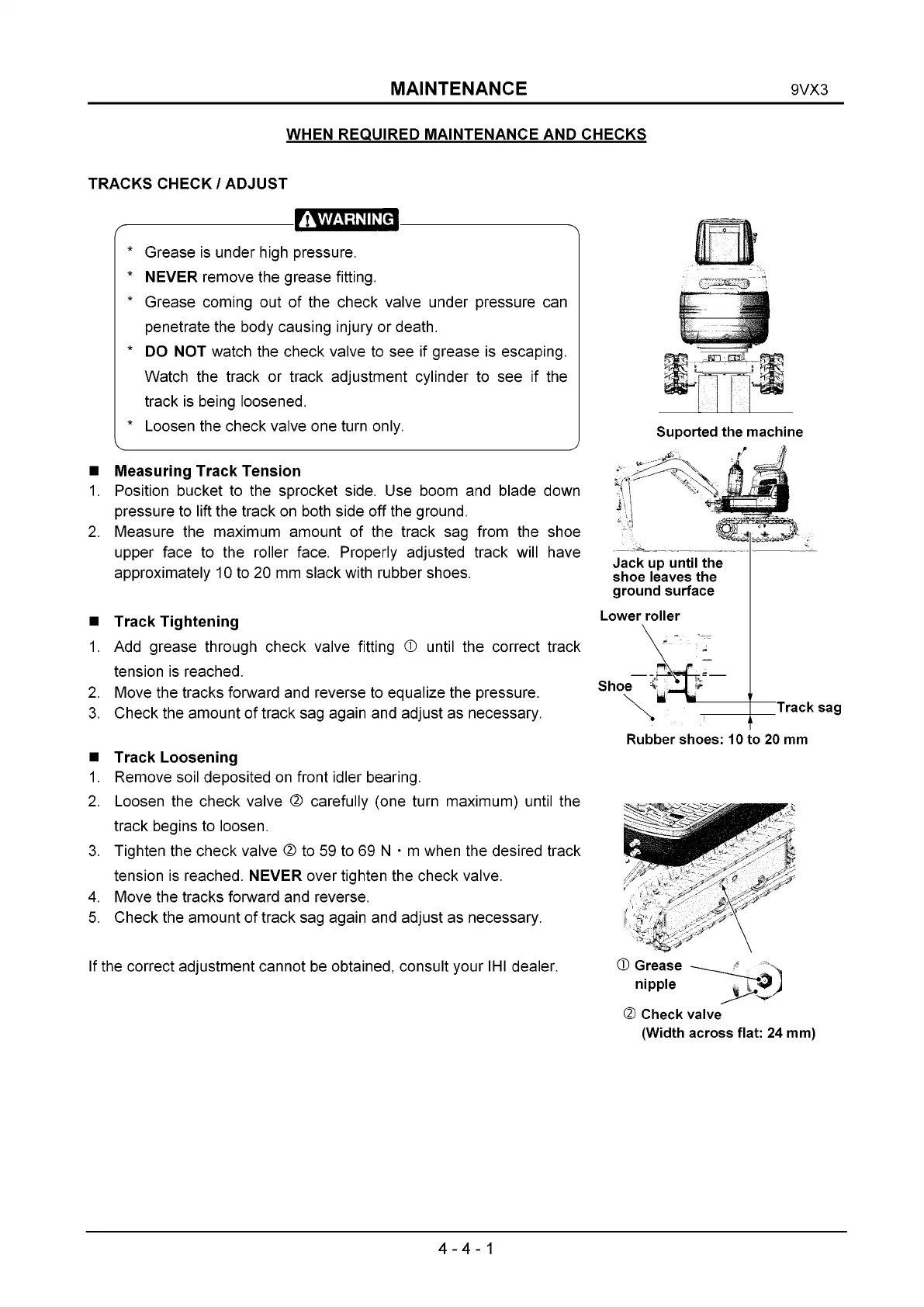

Measuring Track Tension

Position bucket to the sprocket side. Use boom and blade down

pressure to lift the track on both side off the ground.

Measure the maximum amount of the track sag from the shoe

upper face to the roller face. Properly adjusted track will have

approximately 10 to 2 0 mm slack with rubber shoes.

Suported the machine

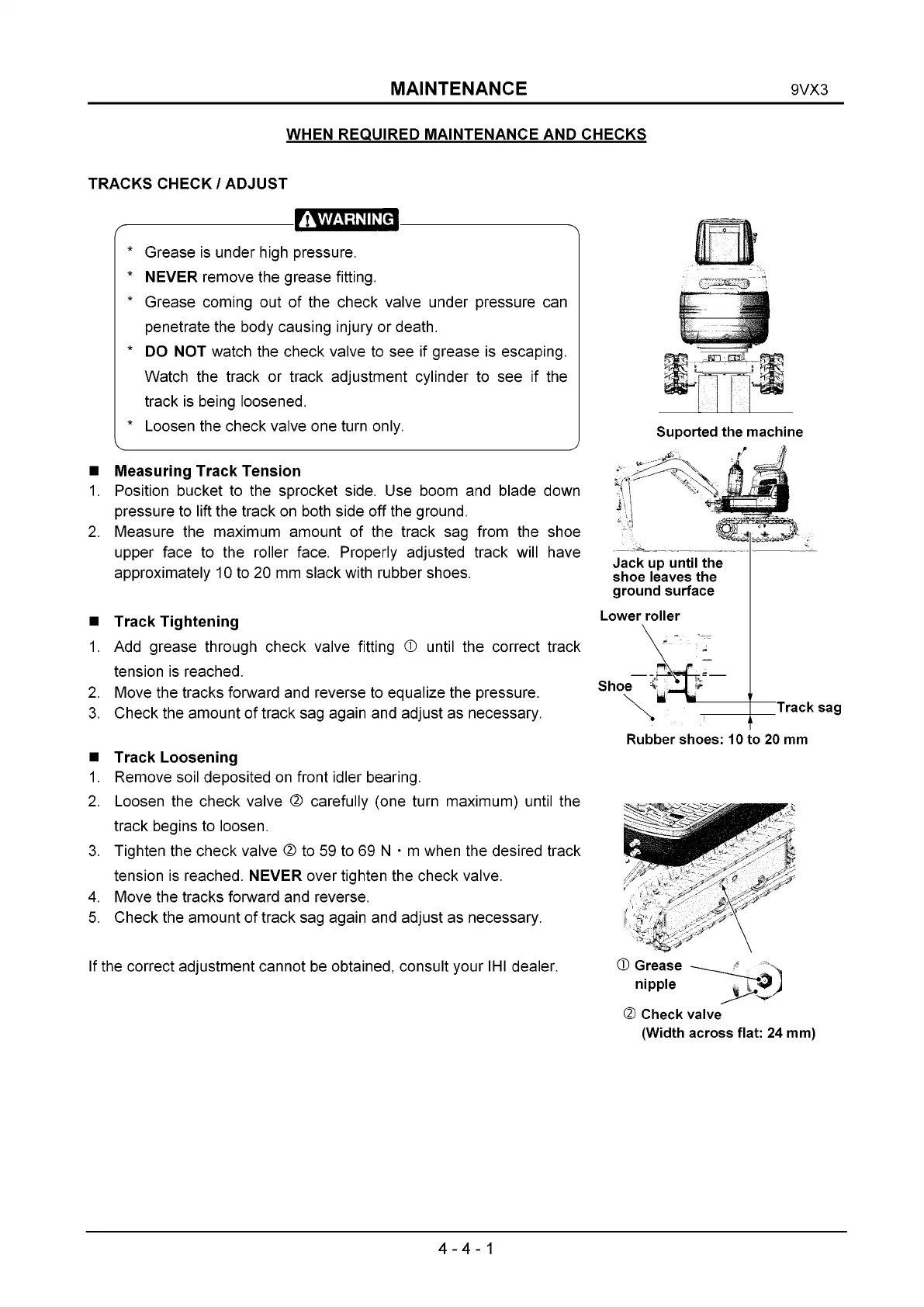

■ Track Tightening

1. Add grease through check valve fitting ® until the correct track

tension is reached.

2. Move the tracks forward and reverse to equalize the pressure.

3. Check the amount of track sag again and adjust as necessary.

■ Track Loosening

1. Remove soil deposited on front idler bearing.

2. Loosen the check valve © carefully (one turn maximum) until the

track begins to loosen.

3. Tighten the check valve © to 59 to 69 N • m when the desired track

tension is reached. NEVER over tighten the check valve.

4. Move the tracks forward and reverse.

5. Check the amount of track sag again and adjust as necessary.

If the correct adjustment cannot be obtained, consult your IHI dealer.

Jack up until the

shoe leaves the

ground surface

Lower roller

Shoe

Track sag

Rubber shoes: 10 to 20 mm

\

\

© Grease

nipple

Check valve

(Width across flat: 24 mm)

4-4-1

Loading...

Loading...