13

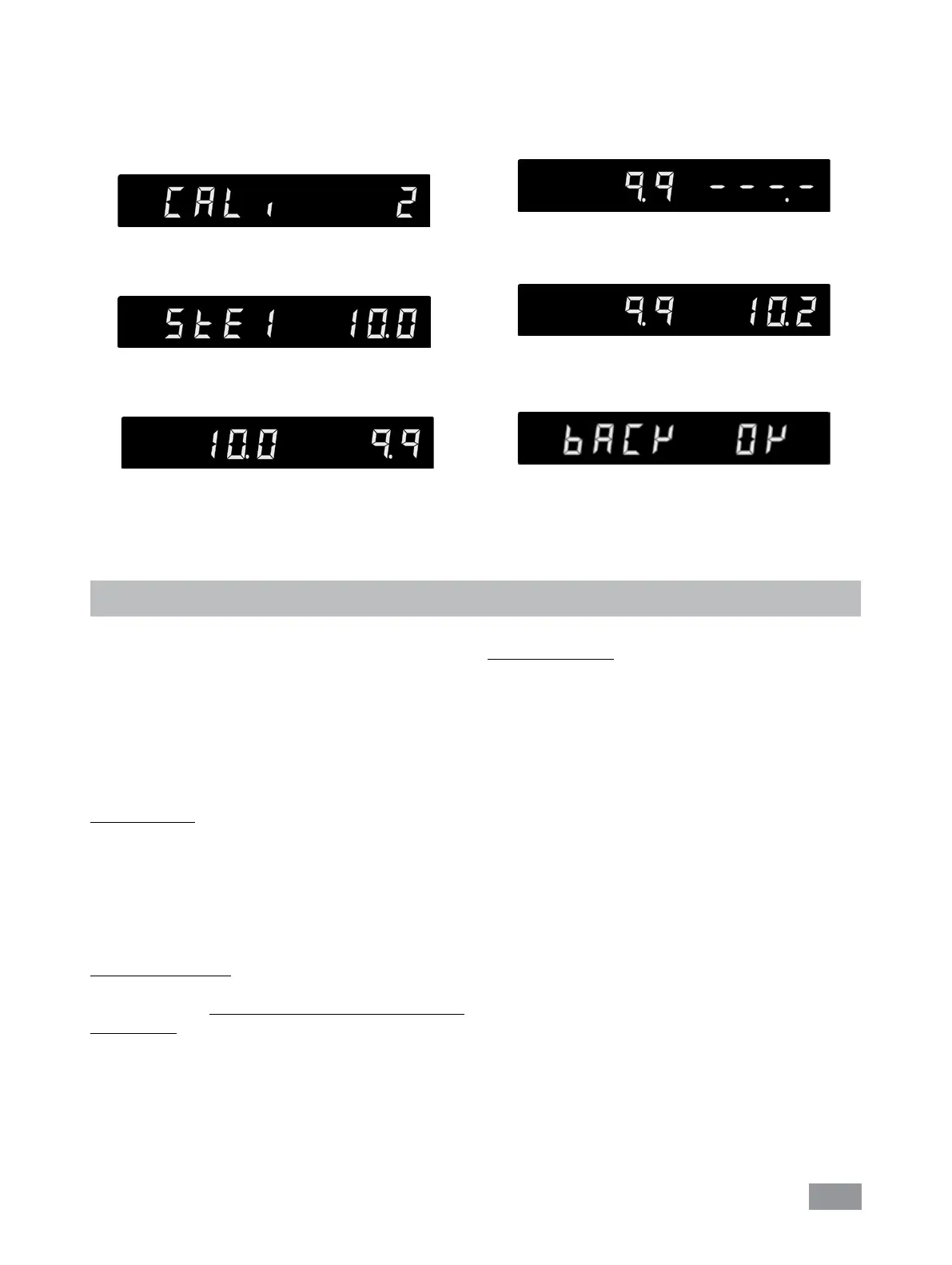

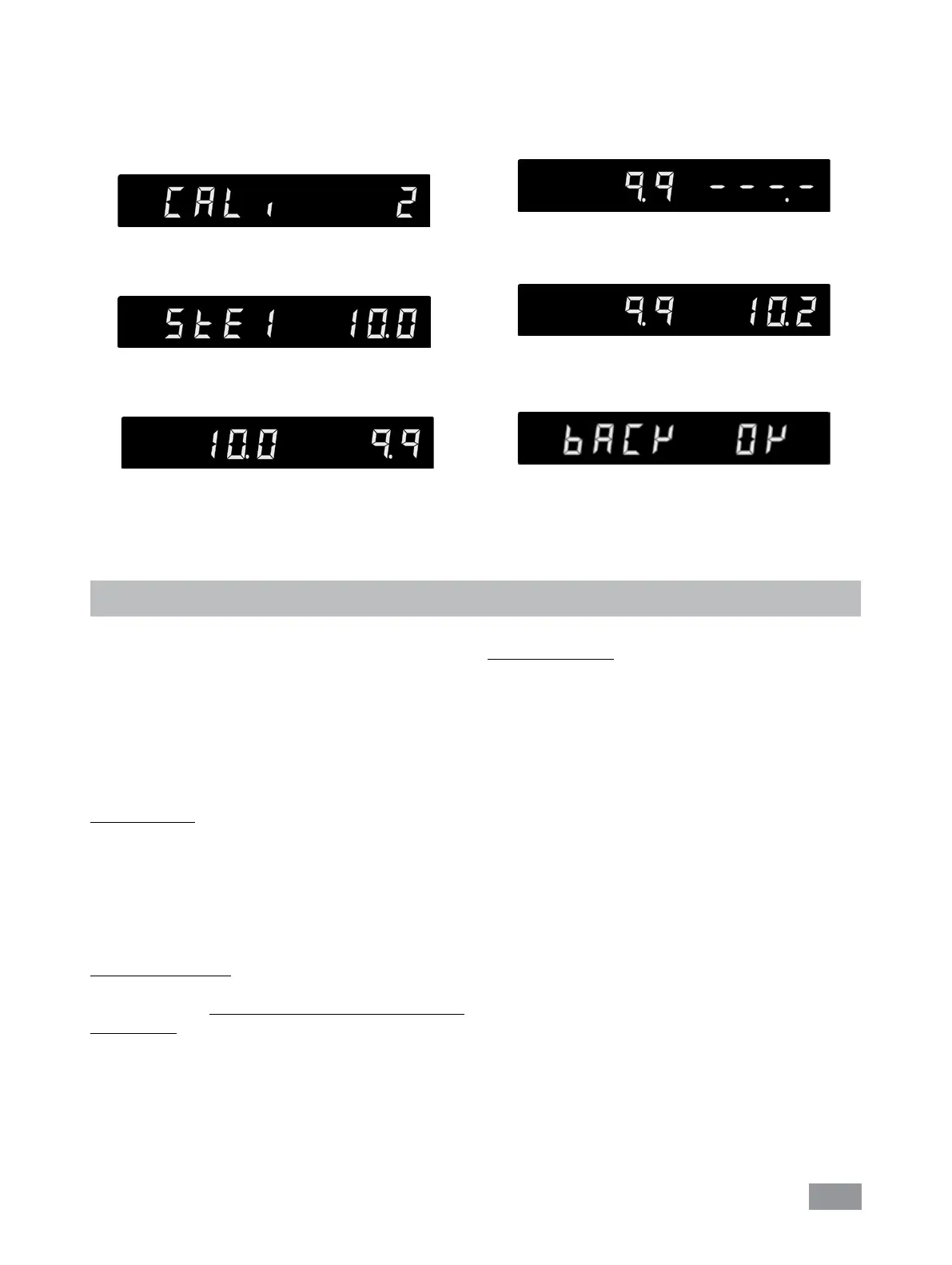

Set the rst point temperature (step 1, e.g. 10 °C) with

“Pump (+)” button (F) or “Pump (-)” button (G). Con-

rm the setting by pressing “OK/Pump“ button (E).

Left area of the display appears the set value (10 °C) and

the right area of the display appears the actual tempera-

ture value measured. The “Set” LED (O) flashes briefly.

The unit now starts and controls to the set value. When

the temperature has reached the set value and has be-

come constant, the “Set” LED (O) no longer flashes and

the following display appears. The temperature mea-

sured by the unit appears on the left hand side.

Input the calibration value from the reference measuring

instrument (e.g. 10.2 °C) with “Pump (+)” button (F) or

“Pump (-)” button (G).

Conrm the value by pressing the “OK/Pump“ button (E).

Back to previous screen for input a new value by press-

ing “Temp” button (B).

Back OK

The rst point calibration is nished now.

Calibration of the other points is performed in the same

way.

Example: 2-point calibration:

Dip the temperature sensor of the reference measuring

instrument into the bath fluid.

Select 2-point calibration in the menu. Press the “OK/

Pump“ button (E) to start the 2-point calibration.

Interface and output

The device can be operated in “Remote” mode via the RS

232 interface (10, see

Fig. 1

) or the USB interface (11, see

Fig. 1

) connected to a PC and with the laboratory soft-

ware Labworldsoft

®

.

Note: Please comply with the system requirements to-

gether with the operating instructions and help section

included with the software.

USB interface:

The Universal Serial Bus (USB) is a serial bus for connect-

ing the device to the PC. Equipped with USB devices can

be connected to a PC during operation (hot plugging).

Connected devices and their properties are automatically

recognized. The USB interface can also be used to update

rmware.

USB device drivers:

First, download the latest driver for IKA

®

devices with USB

interface from http://www.ika.com/ika/lws/download/

usb-driver.zip and install the driver by running the setup

le. Then connect the IKA

®

device through the USB data

cable to the PC.

The data communication is via a virtual COM port. Con-

guration, command syntax and commands of the virtual

COM ports are as described in RS 232 interface.

RS 232 interface:

Conguration

- The functions of the interface connections between the

stirrer machine and the automation system are chosen

from the signals specied in EIA standard RS 232 in ac-

cordance with DIN 66 020 Part 1.

-

For the electrical characteristics of the interface and the

allocation of signal status, standard RS 232 applies in ac-

cordance with DIN 66 259 Part 1.

- Transmission procedure: asynchronous character trans-

mission in start-stop mode.

- Type of transmission: full duplex.

-

Character format: character representation in accordance

with data format in DIN 66 022 for start-stop mode. 1

start bit; 7 character bits; 1 parity bit (even); 1 stop bit.

- Transmission speed: 9600 bit/s.

- Data ow control: none

- Access procedure: data transfer from the stirrer machine to

the computer takes place only at the computer’s request.

Loading...

Loading...