2 3

IMER INTERNATIONAL S.p.A.

IMER MORTAR MIXERS

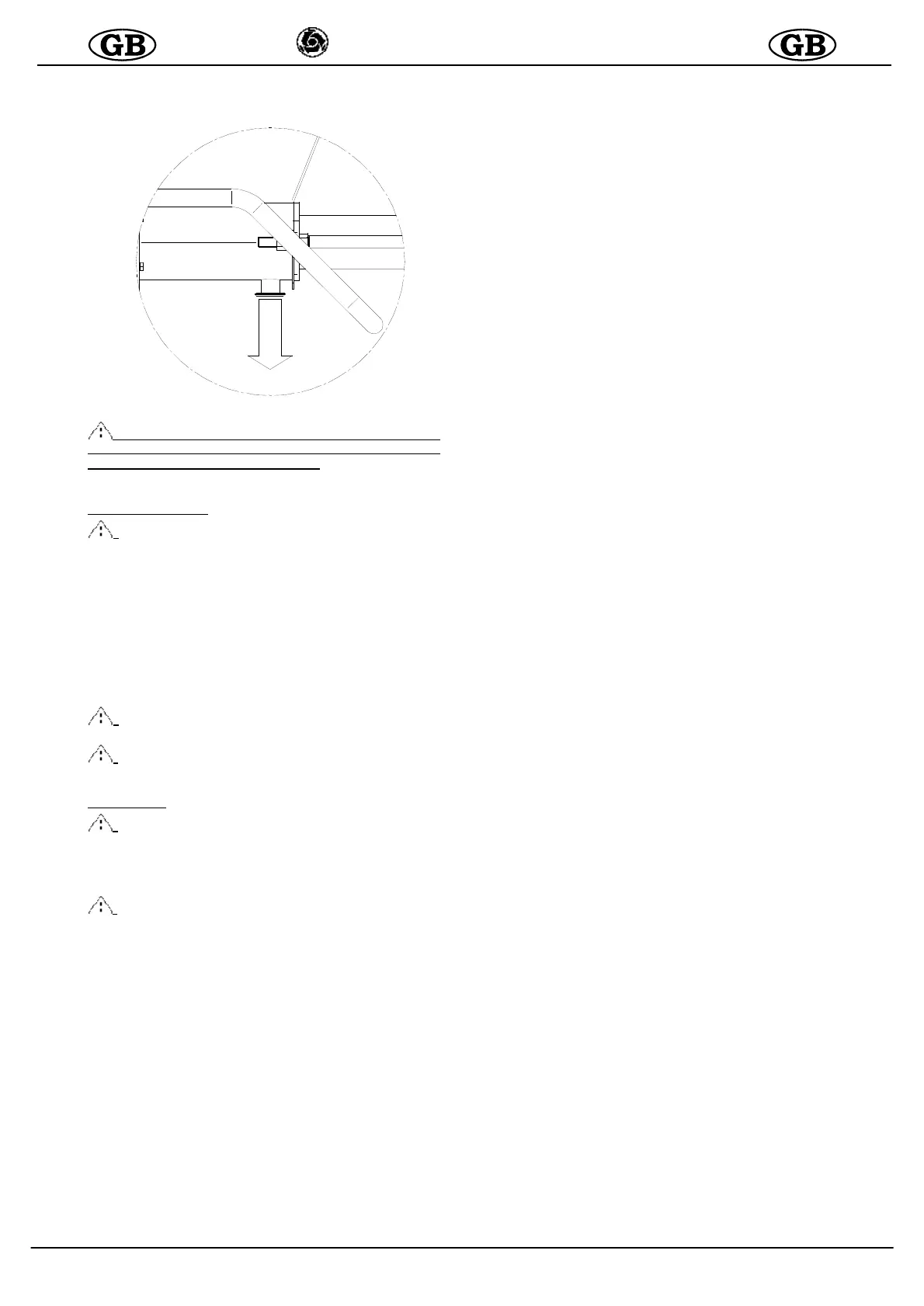

If there is any risk of freezing, open the hopper plug, disconnect

the pipelines and drain all water from the circuit (fig.9).

- Before opening the drain plug or the grid, ensure

that the main switch is turned to 0 and the plug is

disconnected from the power supply.

14. MAINTENANCE

- Maintenance must be performed by adequately

trained personnel, after switching off the machine,

disconnecting it from the power supply and emptying

the hopper.

Check weekly that the compressor air filter is clean. If

deteriorated, replace.

Check weekly that the electric motors are free of dust and dirt

and if necessary clean using compressed air.

Check weekly that the plug and socket contacts are clean, dry

and rust free.

Every six months arrange for an inspection of the machine by

an authorised IMER service centre.

-

Spent oil is a special waste. Therefore it must be

disposed of according to current legislation.

-

Always keep notices and symbols on the machine

legible.

15. REPAIRS

- Never start up the mortar mixer during repairs.

Repairs to the electrical installation must be performed

exclusively by specialised personnel.

Use exclusively original IMER spare parts; modifications

to parts are strictly prohibited.

- If any guards are removed for repairs, ensure they

are refitted correctly at the end of work.

FIG.9

PDF compression, OCR, web-optimization with CVISION's PdfCompressor

Loading...

Loading...