38

IMER INTERNATIONAL S.p.A.

STEP 120

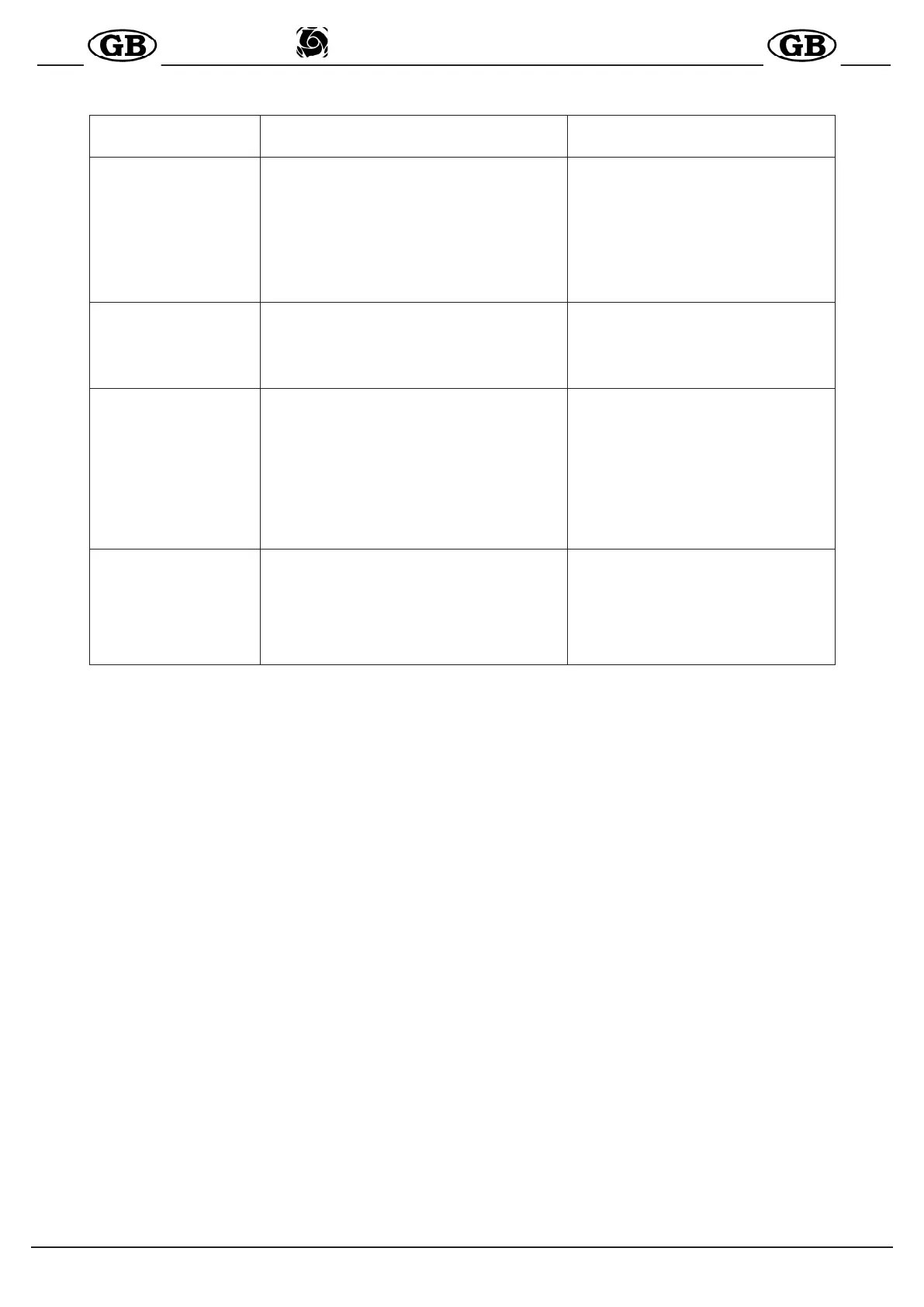

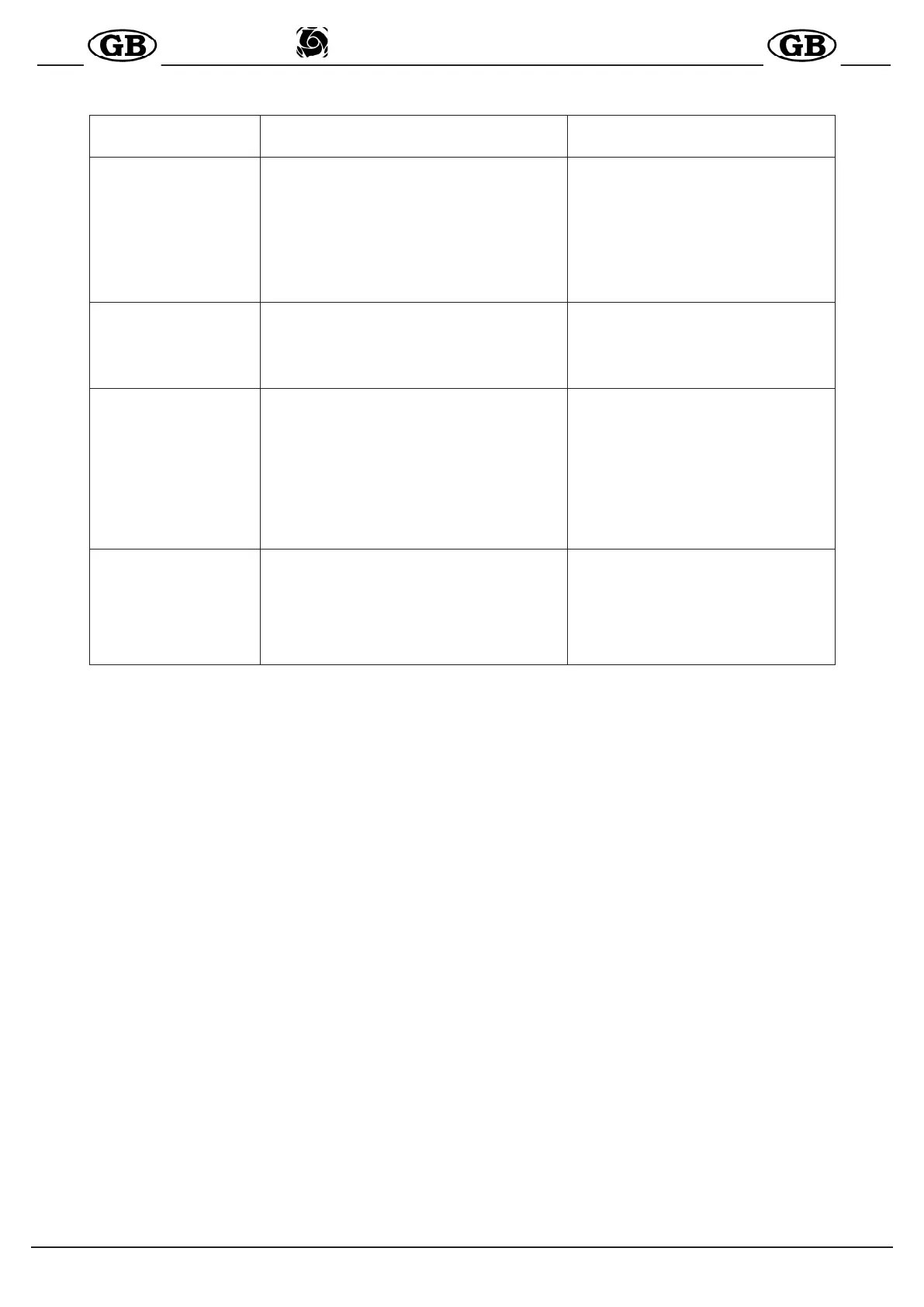

FAULT CAUSE CORRECTIVE ACTION

Machine does not start,

compressor does not

start and the blue light

is OFF

Electric current

- No current delivered to connector of site panel

(fuses)?

- No power delivered to machine

(defective connector connection? loose cable?)

- Main swiitch not turned on

- The supply voltage is too high

- Check the fuses site

- Repair or replace

Insert

- To check that the supply voltage does not

exceed 260V

Machine does not start,

compressor does not

start, On the display is

visualized ---------------------

- The supply voltage is too high - To check that the supply voltage does not

exceed 260V

The machine starts but

stops immediately

BLOCC

ERR00

ERR04

Material

- Material binding properties low

(mortar pump seized?)

- Material too dry

- The supply of voltage during work is too high

-Empty the hopper, ensure that the screw

is not blocked. when the machine is clean,

restart with liquid cement taking care to mix

the solution with at least 400/500 kg of binder

per cubic metre:

- Bring the density of the material equal to

that of a plastering mortar by adding water

- Work with lower ow rates

- To reduce the speed and restart

Material ow to the gun

stops.

A red light illuminates on

the electrical panel

ERR03

ERR04

Clogging

- Material hose clogged

- Spray jet clogged

- Low level of binder in mix

- Sand not suitable for mix

(1*)

- Remove obstruction

- Connection to compressor detached

- Bodies in mix with too large section

- Use sand with constantly optimal particle

size curve.

CAUSE AND CORRECTIVE ACTION MONOPHASE

Loading...

Loading...