39

IMER INTERNATIONAL S.p.A.

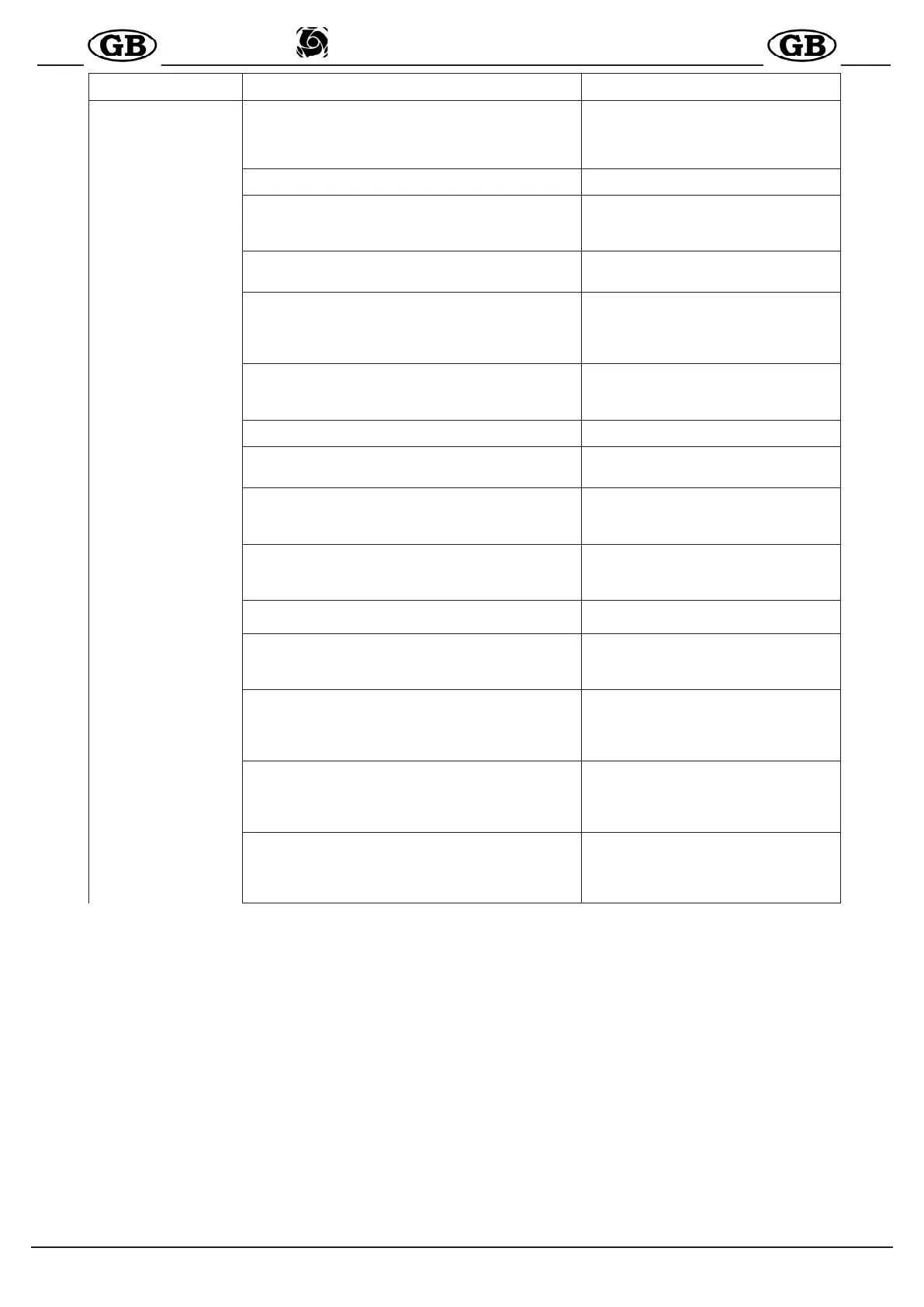

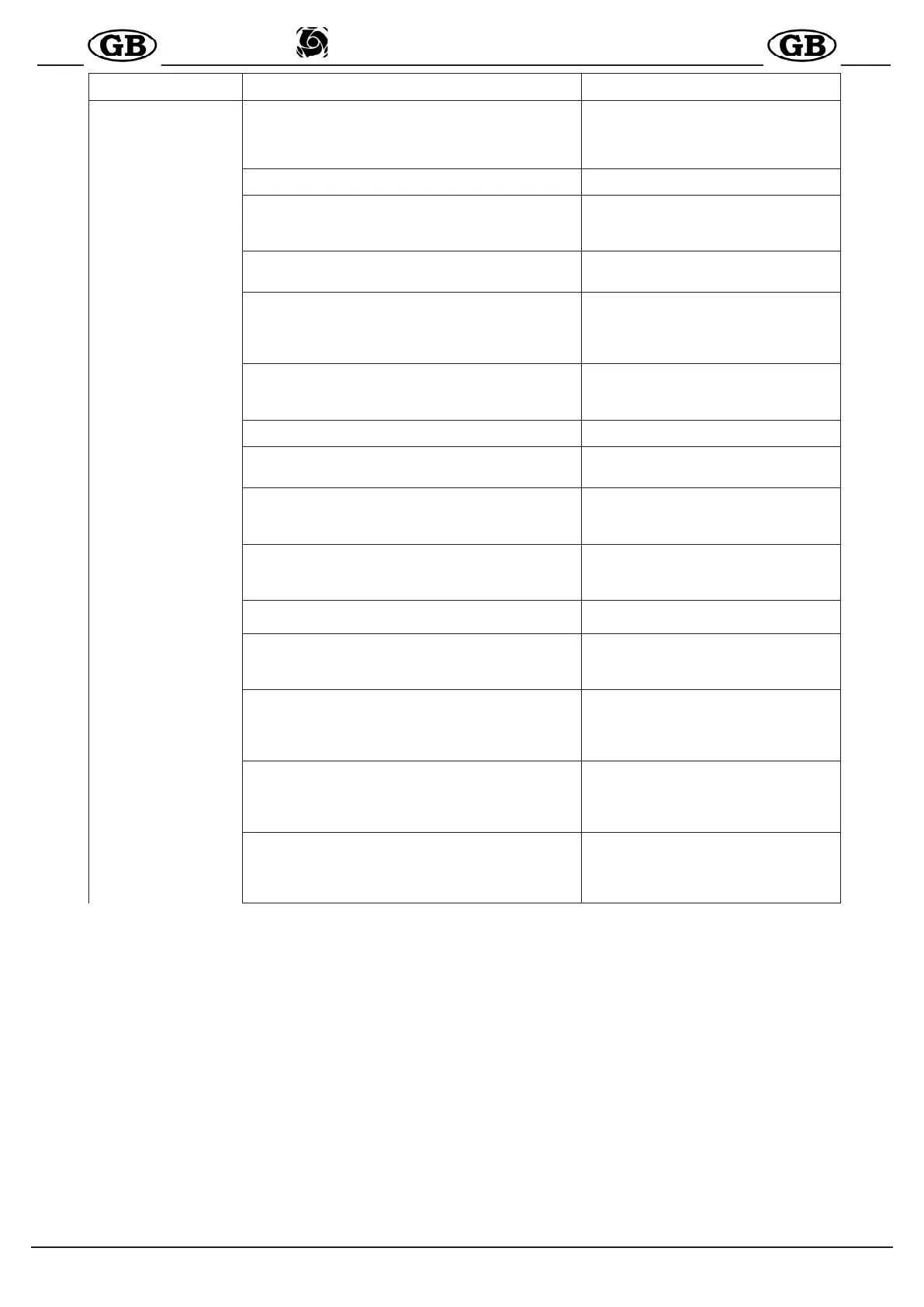

STEP 120

FAULT CAUSE CORRECTIVE ACTION

The machine stops

during operation

- ERR00 : Hopper grille open or incorrectly located.

- Connection plug not inserted

- System malfunction.

- Ensure the grille is properly located

- Insert connection plug

- Contact Assistance Service

- ERR01 : High circuit board temperature (Inverter). - Wait for it cool down

- ERR02 : High screw pump motor temperature.

- The motor has been subjected to overloading for a long

time.

- Wait for it cool down

- ERR03 : Too much power required from screw pump

motor (motor jammed).

- Check the mixture

- Resize the lenght of the piping

- ERR04 : Screw pump motor overload warning. - Check the mixture

- Decrease the speed of the screw pump

motor

- Ensure that the power voltage is > 205V

- ERR05 : The compressor turns on and off too frequently

(<5 start/min)

- High leakage from the piping

-Replace the gaskets

- ERR06 : Compressor blocked at the start - Switch off and switch on the compressor

- ERR07 : Current loss to ground or system malfunction. - Contact Assistance Service.

- Check for water in system.

- ERR 08 : Power voltage too low:

- Lower than 180V for versions 220V

- Lower than 85V for versions 115V

- Check power supply connection

- ERR09 : Overload current on motor vibrating screen - Check the motor vibrating screen

- Disconnect any electrical device on the

power grid

------------ : Voltage input >265V - Check power supply connection

- BLOC : Motor screw pump jammed - Check whether the stator and rotor are

jammed together

- STOP : Inlet air on compressor is closed

- Jet nozzle closed

- Nozzle clogging

- Pipe clogging from machine

- The warning automatically disappears if

the machine starts normally after the halt.

- Clean the air nozzle and unblock the air

hose.

The compressor starts

up repeatedly althou-

gh the air tap put on

the spray jet is closed

-Perforated tube

-Coupling leakage

-Replace the gaskets

-Seal the couplings

-Replace the air tap of the spray jet

The machine is turned

on, the compressor

starts but the screw

doesn't turn

-The air spray outlet is obstructed

-Air hose bended

-Lean nozzle with special cleaner

-To rectie

Loading...

Loading...