5

1

INTRODUCTION

1.1 INTRODUCTION.

Before proceeding to initial startup of the Audax

Top 18-21 ErP units, the personnel in charge

must be familiar with these instructions and

technical installation data.

e Audax Top 18-21 ErP have been designed to

ensure a very high safety level, such to make

installation, start-up, operation and maintenance

easier and safer. If used within their elds of

application, they ensure a safe and reliable

service.

e machines are designed for an operational life

of 15 years, assuming a 75% utilisation factor;

which approximately corresponds to 100.000

hours of operation.

e procedures in this manual are organised in

the same order convenient to install, start,

manage or service these heat pumps.

Make sure you fully understand and implement

all the safety procedures and precautions

contained in the instructions provided with the

machine, as well as those listed in this manual,

which: personal protective equipment, such as

gloves, goggles, safety shoes, suitable tools,

appropriate skills and qualications (electricity,

air conditioning, local legislation).

The conformity of these products with the

European Directives (safety of machinery, low

voltage, electromagnetic compatibility, under

pressure equipment, etc.) can be ascertained by

consulting their declaration of conformity.

1.2 SAFETY.

1.2.1. Considerations about the safety of

installation.

The unit must be carefully inspected once it

reaches the site and before it is put into operation.

In particular, make sure that the cooling circuits

are intact and that no component is deformed or

damaged, for example due to a bump. If in doubt,

perform a leak test. If upon arrival the unit is

found to be damaged, it is essential to immediately

submit a written complaint to the carrier.

is appliance may be used by children of 8 years

or over, and by adults with impaired physical,

sensory or mental abilities, or those inexperienced

or ignorant on the subject if they are properly

supervised or if they have been given instructions

about the safe use of the appliance, and made

aware of the associated risks.

Children must be constantly supervised to ensure

they do not play with the appliance.

Do not remove the pallet or packaging before

the unit reaches the nal installation position.

ese devices can be moved by means of forkli

truck, provided that the forks are inserted only

in the positions indicated on the appliance

itself.

It is also possible to li the units by means of

specic slings (see Par. 2.2).

erefore, to perform liing they must be

harnessed with strong ropes and always strictly

follow the liing instructions stated in the

certied drawings for the appliance.

Safety is only guaranteed provided that such

instructions are strictly followed. Otherwise,

there would be a risk of ruining the material

and injuring the personnel in charge of carrying

out such operations.

NEVER COVER THE SAFETY DEVICES.

e above applies to any fuse caps and safety

valves present in the cooling and heat transfer

uid circuits. Also ensure the presence of caps

on the safety valves outputs. ese caps are

made of plastic and must not be reused. If still

present, remove them. It is essential to install

devices on the outputs of the safety valves or

on the free ends of the drainage lines possibly

connected to them, that inhibit the penetration

of foreign bodies (dust, debris, etc.) and/or of

rainwater that may cause the formation of rust

or ice caps. Just like the drainage lines, these

devices must not prevent operation or cause

head losses in excess of 10% of the controlled

pressure.

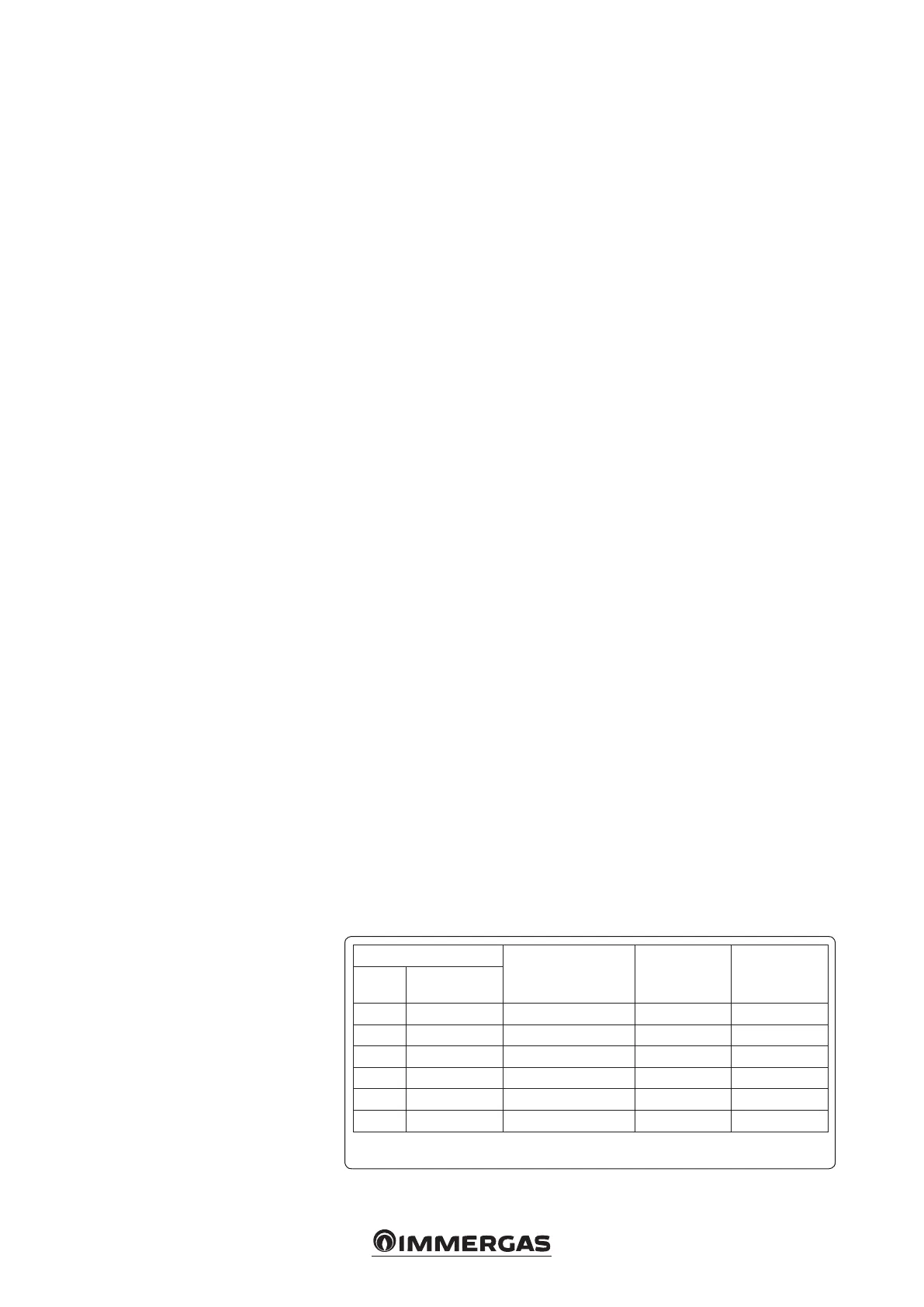

Classication and control

In accordance with Pressure Equipment

Directive and EU regulations on monitoring

and use at national level, the protective devices

of these machines are classied as in table 1-1:

Do not remove the valves and fuses, not even

for those plants where the risk of re is under

strict control. is is due to the fact that there

would be no guarantee that these accessories

would be reassembled in case of change in the

system features or transport of the gas load

appliance.

Should the unit be subject to re, the safety

devices prevent breakage due to the overpressure

releasing the coolant. erefore, the uid can

be decomposed in toxic residues when subjected

to ame, and therefore:

• Keep away from the unit.

• Set warnings and recommendations for

personnel to stop a re.

• e re extinguishers suitable for the system

and type of coolant must be easily accessible.

All factory-installed pressure relief valves

are sealed to prevent any alteration in their

calibration.

e drain valves must be periodically checked.

See Par. 1.2.4. “Considerations about the safety

of repair interventions”.

Provide a drain ditch in the drain circuit, in

the vicinity of each drain valve, to avoid an ac-

cumulation of condensate or rainwater.

e coolant must be handled carefully fol-

lowing all legislation requirements locally

applicable.

e accumulation of coolant inside an enclosed

space could decrease the oxygen and cause suf-

focation or explosions.

e inhalation of high concentrations of va-

pour is harmful and may cause heart failure,

loss of consciousness or death. Being heavier

than air, the steam reduces the amount of

oxygen available for breathing. ese products

cause eye and skin irritation. Decomposition

products can be hazardous.

Intervention

Name of technician

responsible for

commissioning

National

regulations

applicable

Verication

body

Date

Type of

intervention

(1)

(1) Maintenance, repairs, regular checks (EN 378), leaks, etc.

1-1

Loading...

Loading...