1-11

1

1

2

3

4

6

5

7

8

9

9

INSTALLERUSER

MAINTENANCE TECHNICIAN

Pump anti-seizure

Audax TOP ErP units are equipped with an an-

ti-seizure protection of the pump's motor sha.

For this function to operate correctly, the system

must not be emptied and supply voltage must not

be disconnected during long periods of inactivity.

However, if the pump rotor sha should seize

after long periods of inactivity, the operator

should do as follows in order to release it (only

for Audax TOP 12-16 ErP):

- Disconnect voltage

- Remove the front panel

- Loosen the sha's protection cap at the rear

of the pump

- Insert a at-blade screwdriver into the groove

and turn the rotor's sha

- Reassemble the protection cap

- Supply voltage to the system

Cleaning the system and Water features

With new installations or when emptying the

circuit, preventive cleaning of the system must

be carried out.

In order to ensure proper operation of the prod-

uct, aer each cleaning operation, replace water

or top up glycol. Make sure the liquid is clear, is

without any visible impurities and the hardness

is below 20°f.

Antifreeze protection

If the device is kept o during the winter months

with the room temperature below 0°C and glycol

is not used in the hydraulic system, it is recom-

mended to empty the entire system by draining

the unit (Fig. 1-9, point 3) and the system's

discharge valve (Fig. 1-11, point 5).

System minimum water content

Minimum water content is mainly important to

provide proper execution of defrosting cycles.

In this regard, the minimum amount of water

to ensure is:

AUDAX TOP 6-8-12-16 ErP → 6 l/kW for any

type of system.

N.B.: it is also important to check that the

dehumidier line has a minimum of 3 l/kW

(dehumidier hydraulic circuit connection).

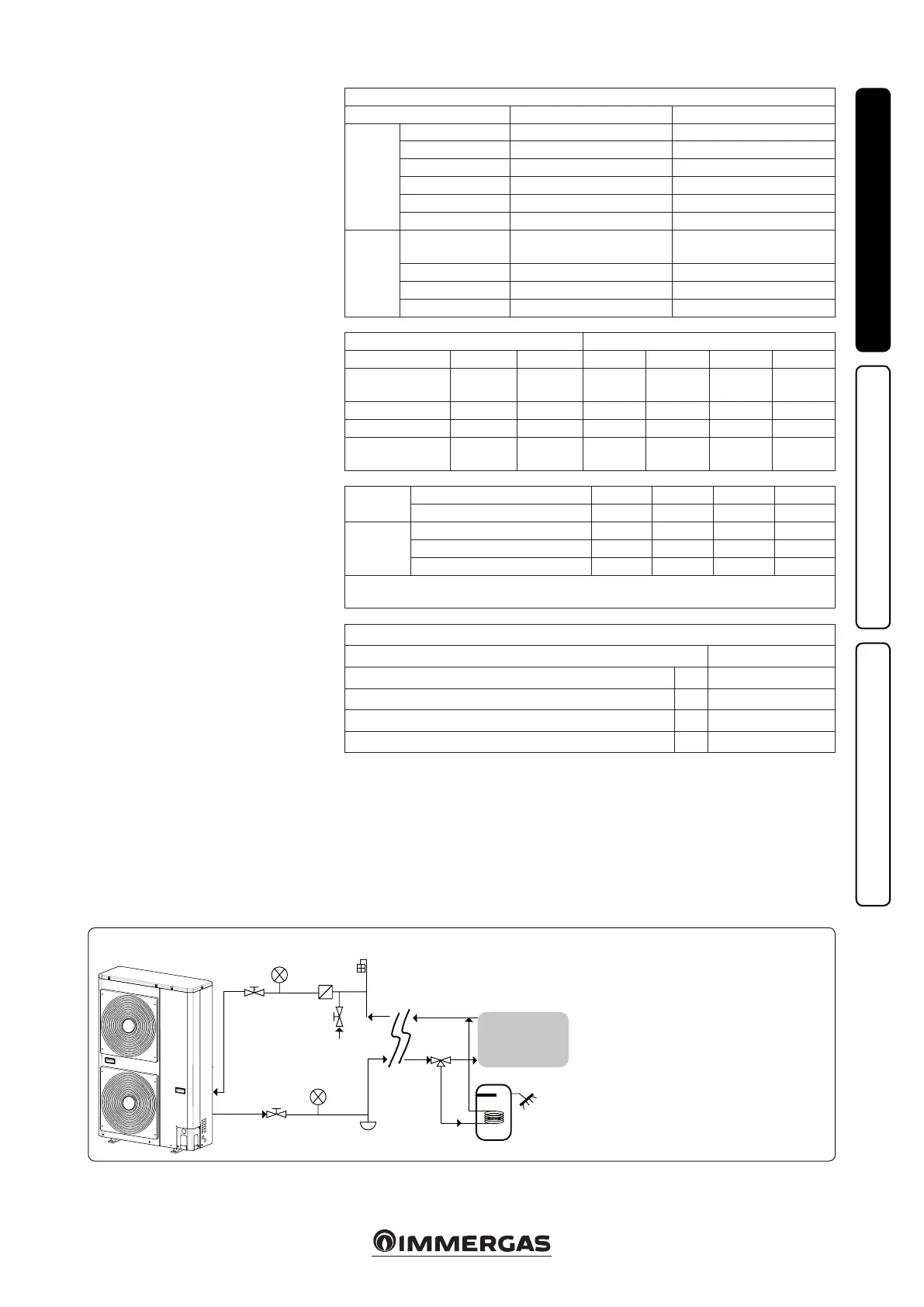

Pipe content

Inside diameter External diameter Litres/metre

Copper

12 mm) 14 mm) 0.11 l/m

14 mm) 16 mm 0.15 l/m

16 mm) 18 mm 0.20 l/m

20 mm) 22 mm 0.31 l/m

25 mm) 28 mm) 0.49 l/m

32 mm) 35 mm 0.80 l/m

Steel

“12.7 mm (1/2”)” 3/8” Gas 0.13 l/m

“16.3 mm (5/8”)” 1/2” Gas 0.21 l/m

“21.7 mm (7/8”)” 3/4” Gas 0.37 l/m

“27.4 mm (11/16”)” 1” Gas 0.59 l/m

Unit Audax TOP ErP

6 8 12 16

Nominal water

input

Std l/s 0.28 0.33 0.58 0.69

Operating Pressure Max kPa 300 300 300 300

Filling pressure Min kPa 120 120 120 120

Unit lowest level

dierence

Max m 20 20 20 20

% Glycol 10% 20% 30% 40%

Freezing Temperature (*) -4 °C -9 °C -15 °C -23 °C

Correction

Factors

Capacity 0.996 0.991 0.983 0.974

Absorbed Power 0.990 0.978 0.964 1.008

Heat loss 1.003 1.010 1.020 1.033

(*) N.B.: the temperature values are indicative.

Always refer to the temperature levels indicated regarding the specic product used.

TABLE USED TO CALCULATE THE WATER CONTENT IN THE SYSTEM

Installed Unit

Unit content (*) I

Pipe content (**) I

Utilities (fan coils, panels, radiators, etc.) (***) I

Total content (****) I

(*) Consult the technical specications table

(**) Consult the water pipes content table

(***) Consult the manual regarding utilities

installed

(****) e content of water in the system must be

above 6 litres per kW of machine power

(e.g. Audax TOP 12kW, 6x12 = more than 72

litres).

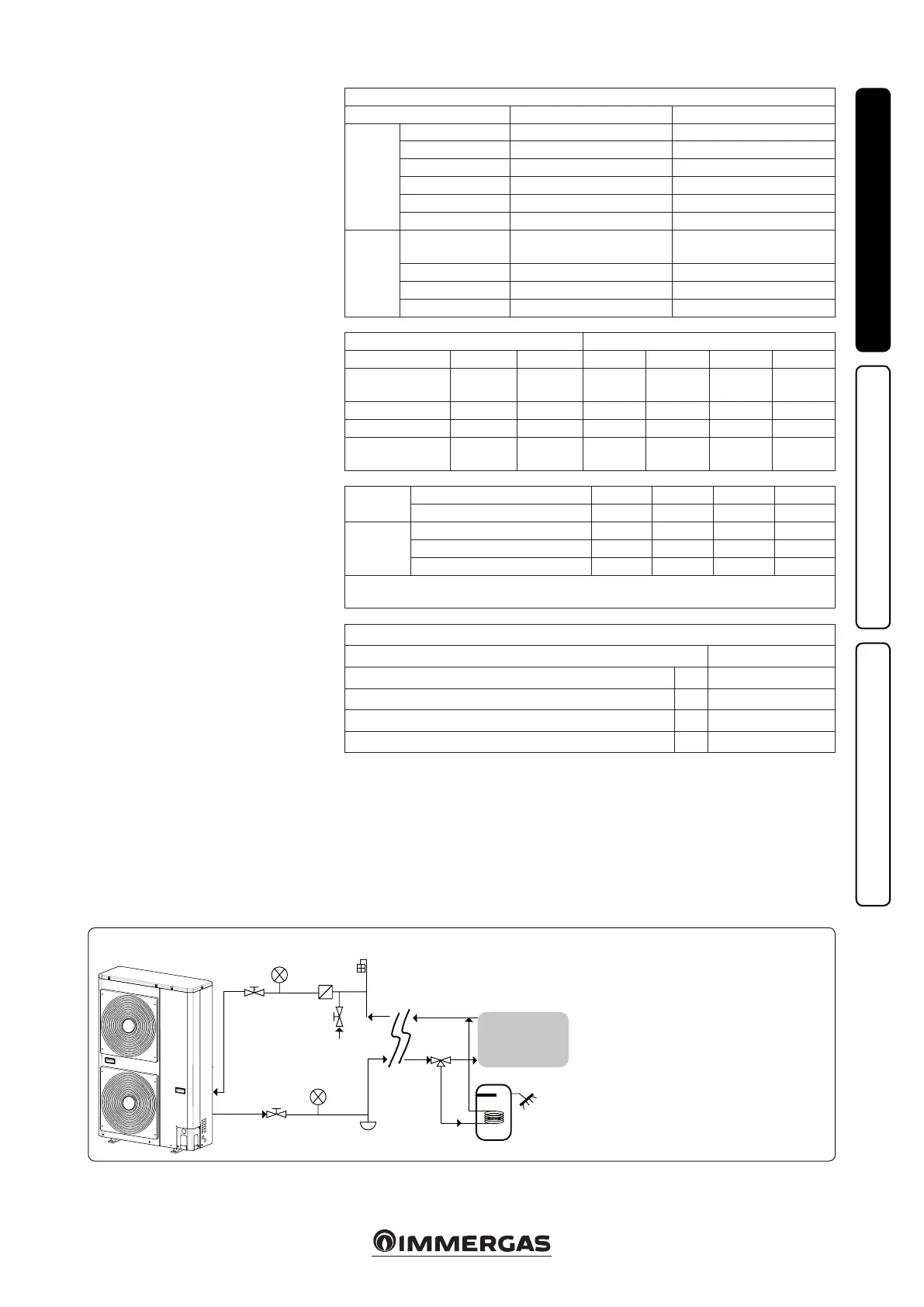

Key:

1 - Shut-o valve

2 - Water line lters (10 links/cm

2

)

3 - Manometer

4 - Filling valve

5 - System draining valve (in the lowest points of the

circuit)

6 - Air vent valve (in the highest points of the circuit)

7 - 3-way valve

8 - DHW storage tank

9 - Internal utility

Typical diagram of a hydraulic circuit for Audax TOP ErP units

Attention: do not use the heat pump to treat

industrial process water, swimming pool water

or DHW.

In all these cases, provide an intermediate heat

exchanger.

Loading...

Loading...