6

LP

GP

G

RU

RR

SC

R

M

LP

GP

G

R

M

MU

RU

SC

V

RR

MU

1

2

3

4

3

INSTALLERUSERMAINTENANCE TECHNICIAN

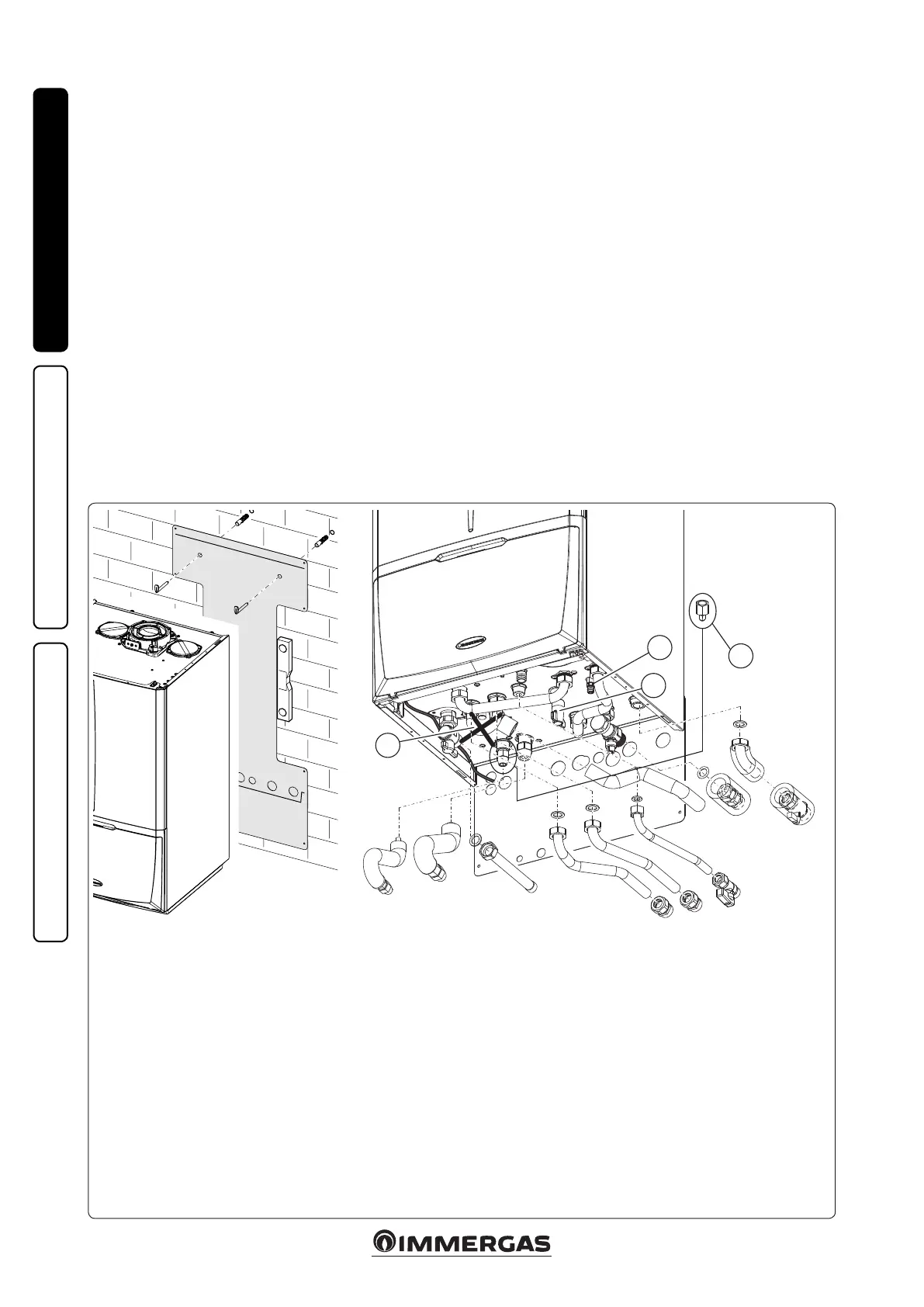

e hydraulic connection kit includes:

N° 2 - adjustable expansion bolts

N° 2 - indoor unit support hooks

N° 1 - Gas supply pipe Ø 18 (G)

No. 1 - 1/2” system lling inlet pipe (RR)

N° 1 - 3/4” storage tank unit ow pipe (MU)

N° 1 - 3/4” storage tank unit return pipe (RU)

N° 1 - 1/2” ball valve (RR)

N° 1 - 3/4” system return pipe (R)

N° 1 - 3/4” system ow pipe (M)

N° 1 - 3/4” ball valve (M)

N° 3 - Insulating sheath for system pipes (R - M)

N° 1 - Telescopic tting 3/4” (MU)

N° 1 - 3/4” telescopic tting (RU)

Gaskets, screws and seal O-Ring

e R410A circuit wall connection kit (optional)

includes:

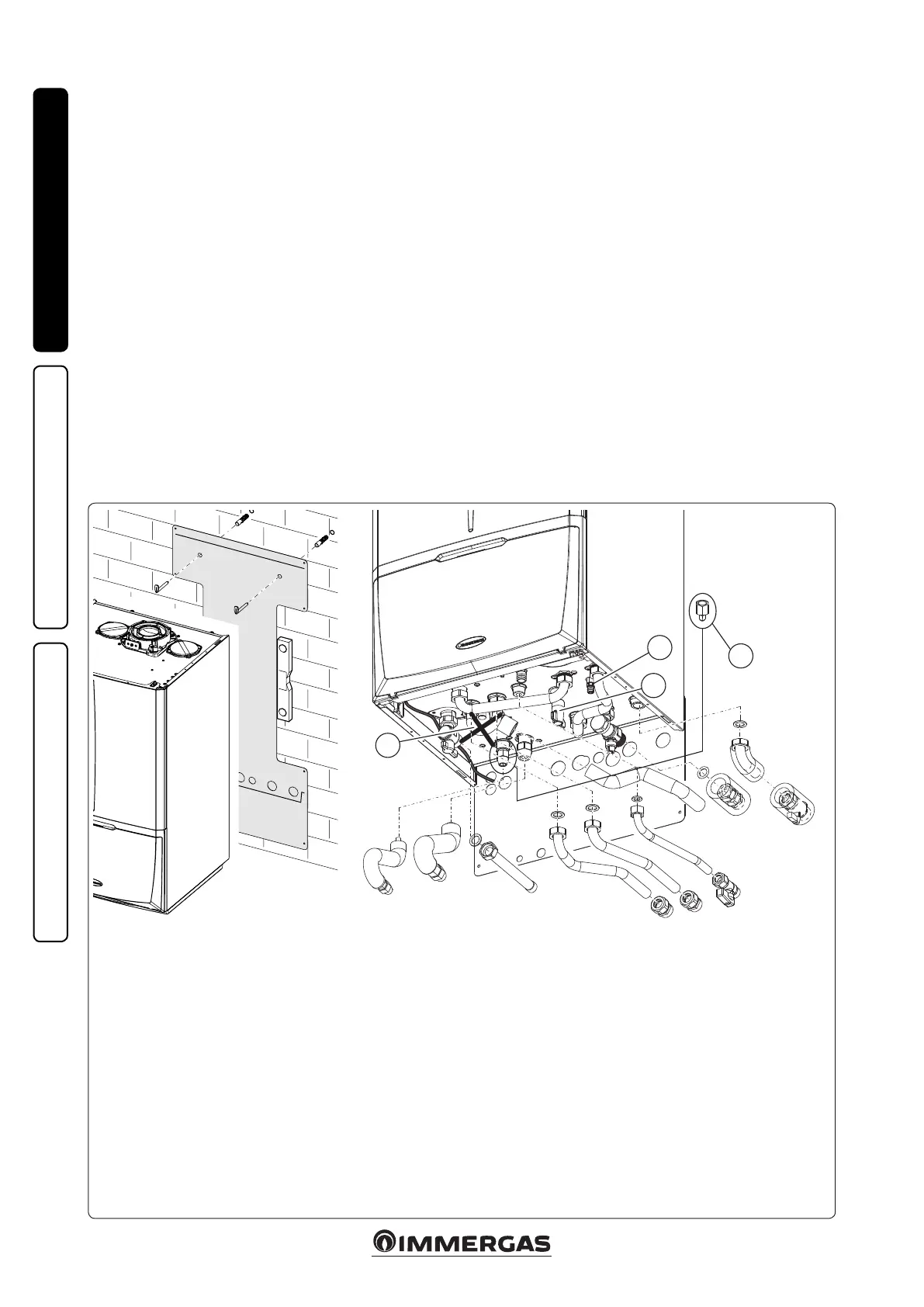

1.4 CONNECTION GROUP.

- The hydraulic connection unit is standard

supplied with Magis Combo Plus. Make the

hydraulic connection as shown below, making

sure to protect the system ow and return pipes

with their supplied insulating sheaths.

- The R410A circuit wall connection unit is

supplied as an extra kit. Connect the circuit,

following the instructions provided in the

condensing unit instructions booklet.

1.5 HYDRAULIC CONNECTION.

Attention: in order not to void the product war-

ranty, before making unit connections, carefully

clean the heating system (pipes, radiators, etc.)

with special pickling or de-scaling products to

remove any deposits that could jeopardise proper

indoor unit operation.

Treatment of the thermal system water is re-

quired by law, in order to protect the system and

the appliance from deposits (e.g., lime scale),

slurry or other hazardous deposits. Water con-

nections must be made in a rational way using the

couplings on the indoor unit template.

e safety valve outlet of the indoor unit must

be connected to a draining funnel. Otherwise,

the manufacturer of the indoor unit declines

any responsibility in case of ooding if the drain

valve cuts in.

Attention: the manufacturer declines all liability

in the event of damage caused by the installation

of an automatic lling system.

In order to meet the system requirements es-

tablished by EN 1717 regarding the pollution

of drinking water, we recommend installing the

IMMERGAS anti-backow kit upstream of the

hydronic unit cold water inlet connection. We

also recommend using a category 1, 2 or 3 heat

transfer uid (ex: water + glycol) in the hydronic

unit primary circuit (CH circuit), as dened in

the EN 1717 standard.

Attention: to preserve appliance duration and

eciency features, we recommend installing a

suitable water treatment device if the water has

features that can lead to limescale deposits.

Condensate drain. To drain the condensate pro-

duced by the appliance, it is necessary to connect

to the drainage system by means of acid conden-

sate resistant pipes, with an internal Ø of at least

13 mm. e system connecting the appliance to

the drainage system must be carried out in such

a way as to prevent occlusion and freezing of the

liquid contained in it. Before appliance ignition,

ensure that the condensate can be correctly re-

moved. Aer rst ignition, check that the drain

trap is lled with condensate (Para. 1.23). Also,

comply with national and local regulations on

discharging waste waters.

In the event condensate is not discharged into

the wastewater drainage system, a condensate

neutraliser must be installed to ensure com-

pliance with the parameters established by the

legislation in force.

Attention: if you are using one or more booster

pumps it is essential to install a hydraulic sep-

arator (not supplied by Immergas) downstream

of the indoor unit.

N° 1 - G 3/8” liquid phase chiller line pipe (LP)

N° 1 - G 5/8” gaseous phase chiller line pipe (GP)

Already installed on the module:

N° 1 - Gas cock

N° 1 - System interception tap with 3/4” lter (R)

Key:

V - Electrical connection

G - Gas supply

RU - Storage tank unit return

MU - Storage tank unit ow

RR - System lling

SC - Condensate drain (minimum internal diame-

ter Ø 13 mm)

R - System return

M - System ow

LP - Chiller line - liquid phase

GP - Chiller line - gaseous phase

1 - System lling valve

2 - System draining valve

3 - Storage tank unit bypass pipe, to be used only

in case of heat generator operating in room

heating mode only

4 - G 3/8"F - 1/4" SAE M reduction

(supplied with Audax Pro 5kW; to be used

only in pairing with this model)

Loading...

Loading...