ENGLISH

31

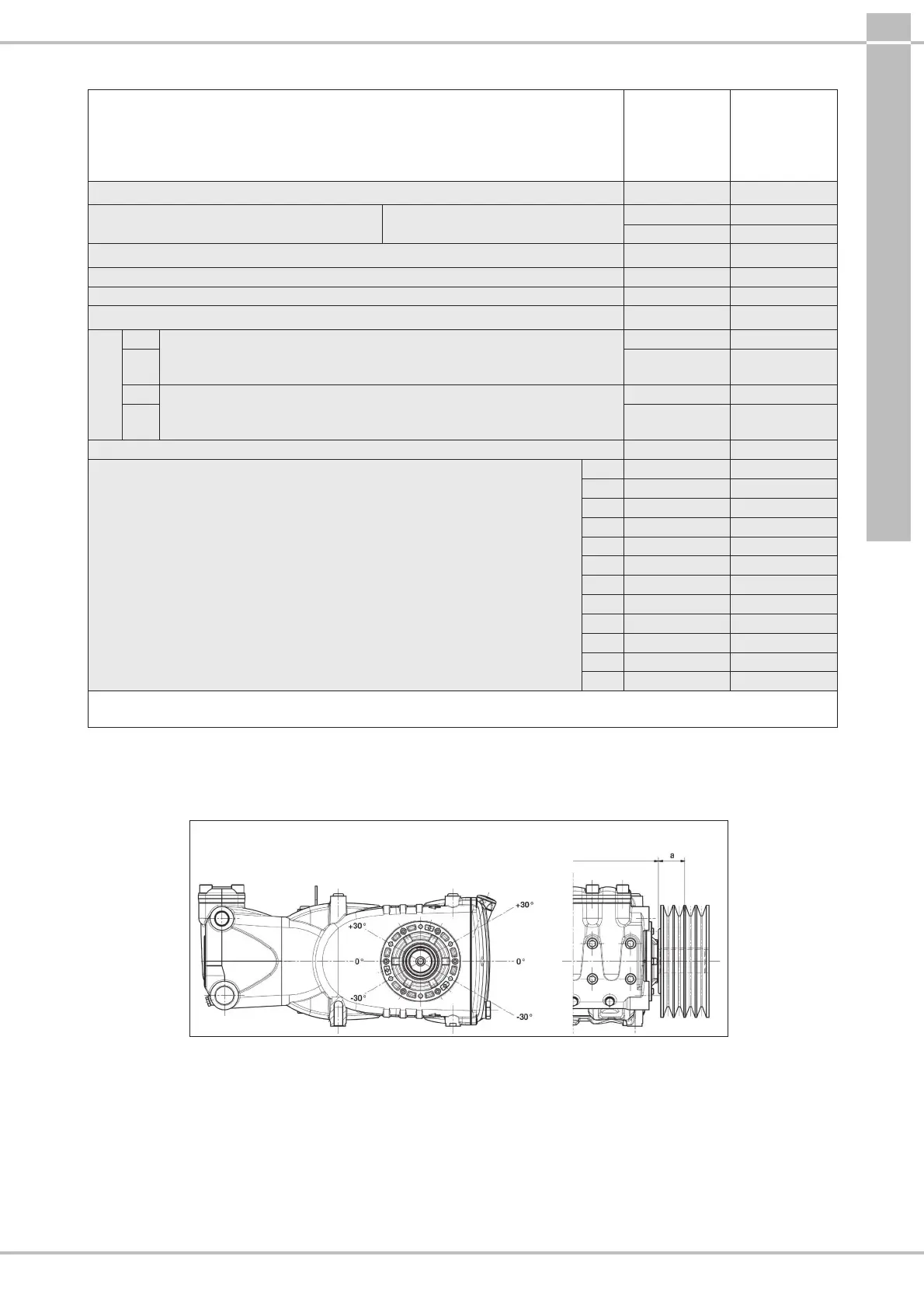

Dimensions (inmm)

Belt section as per DIN symbol

DIN 7753 part 1 and B.S. 3790 symbol B.S./ISO

Belt section as per DIN symbol

DIN 2215 and B.S. 3790 symbol B.S./ISO

XPB/SPB

SPB

17

B

XPC/SPC

SPC

22

C

Pitch width b

w

14.0 19.0

Increased grooving width b

1

≈

α = 34° 18.9 26.3

α = 38° 19.5 27.3

c 8.0 12.0

Distance between grooving e 23 ± 0.4 31 ± 0.5

f 14.5 ± 0.8 20.0 ± 1.0

Increased grooving depth t

min

22.5 31.5

α 34° by primitive diameter d

w

from 140 to 190 from 224 to 315

38°

narrow-section V-belts

DIN 7753 part 1

> 190 > 315

α 34° by primitive diameter d

w

from 112 to 190 from 180 to 315

38°

classic section V-belts

DIN 2215

> 190 > 315

Tolerance for α = 34°-38° ± 1° ± 30’

Pulleys for b2 by grooving number z

b2 = (z-1) e + 2 f

1 29 40

2 52 71

3 75 102

4 98 133

5 121 164

6 144 195

7 167 226

8 190 257

9 213 288

10 236 319

11 259 350

12 282 381

Minimum pulley diameter must be respected.

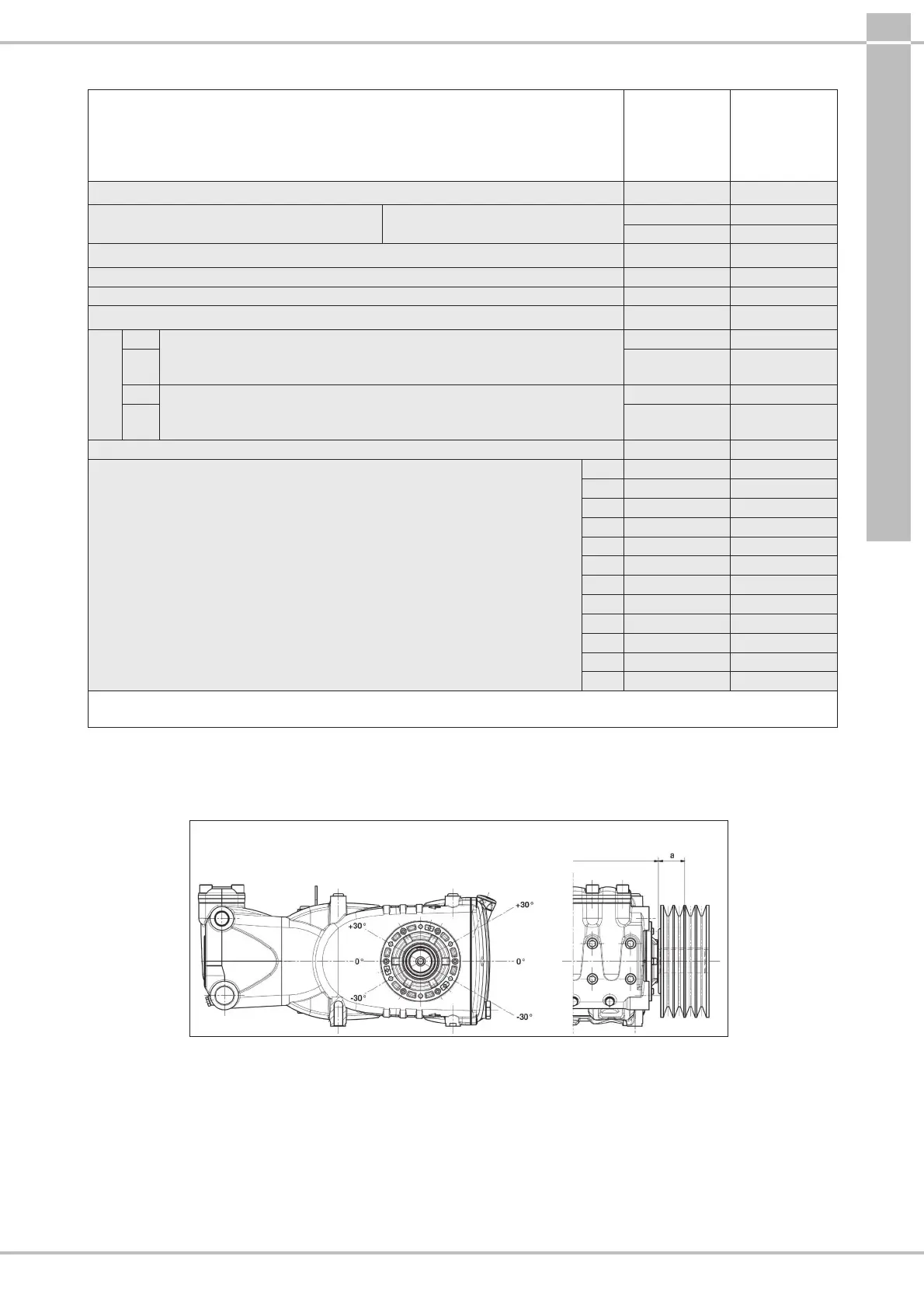

Do not use laminated V-belts. Fig.9

b) Use high performance belts – for example XPB instead of

SPB – as a lower quantity of belts for the same transmitted

power may be necessary and a consequent shorter

resulting distance compared to the shaft shoulder (P.T.O)

“a“ of Fig.10.

Shaft

shoulder

(P.T.O.)

Fig.10

c) Pull the belts according to manufacturer instructions.

Excessive pulling can cause reduced bearing life and wear

out the pulley prematurely. Pulling depends on dierent

variables as indicated in par.9.12.

d) Belt length has a natural tolerance ≥ ± 0.75%. For this

reason, the 2 belts must be purchased as a pair.

e) Follow the direction of the belt pull as shown in Fig.9 for

other needs, contact our Technical or Customer Service

Departments.

f) Take care of the alignment of the driving pulley and driven

pulley grooves.

Loading...

Loading...