ENGLISH

27

9 PUMP INSTALLATION

9.1 Installation

The pump must be xed horizontally using the M16x1.5

threaded support feet. Tighten the screws with a torque of 210

Nm.

The base must be perfectly at and rigid enough as not to

allow bending or misalignment on the pump coupling axis/

transmission due to torque transmitted during operation.

The unit cannot be xed rigidly to the oor but must

interposed with vibration dampers.

For special applications contact the Technical or Customer

Service Departments.

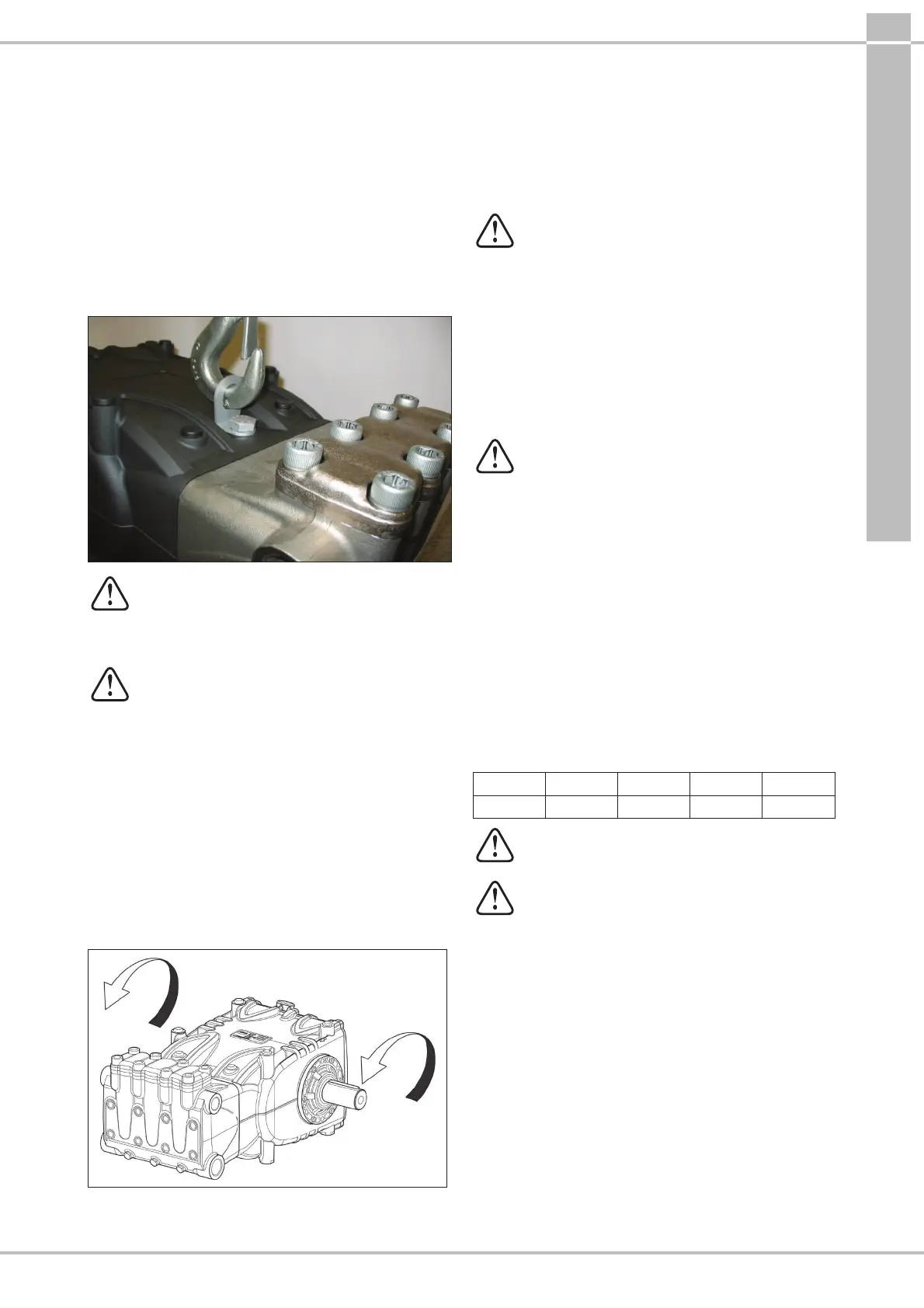

A lifting bracket is mounted on the pump for easy installation,

as per the gure below.

Replace the oil lling hole closing service plug

(red) positioned on the rear casing cover. Check

the correct quantity with the oil dipstick.

The oil dipstick must always be reachable, even

when the unit is assembled.

The pump shaft (PTO) should not be rigidly

connected to the propulsion unit.

The following types of transmission are

recommended:

- Hydraulics by ange, for proper application

consult with our Technical or Customer Service

Departments.

- V-belts.

- Cardan-shaft (comply with manufacturer's Max.

recommended working angles).

- Flexible joint.

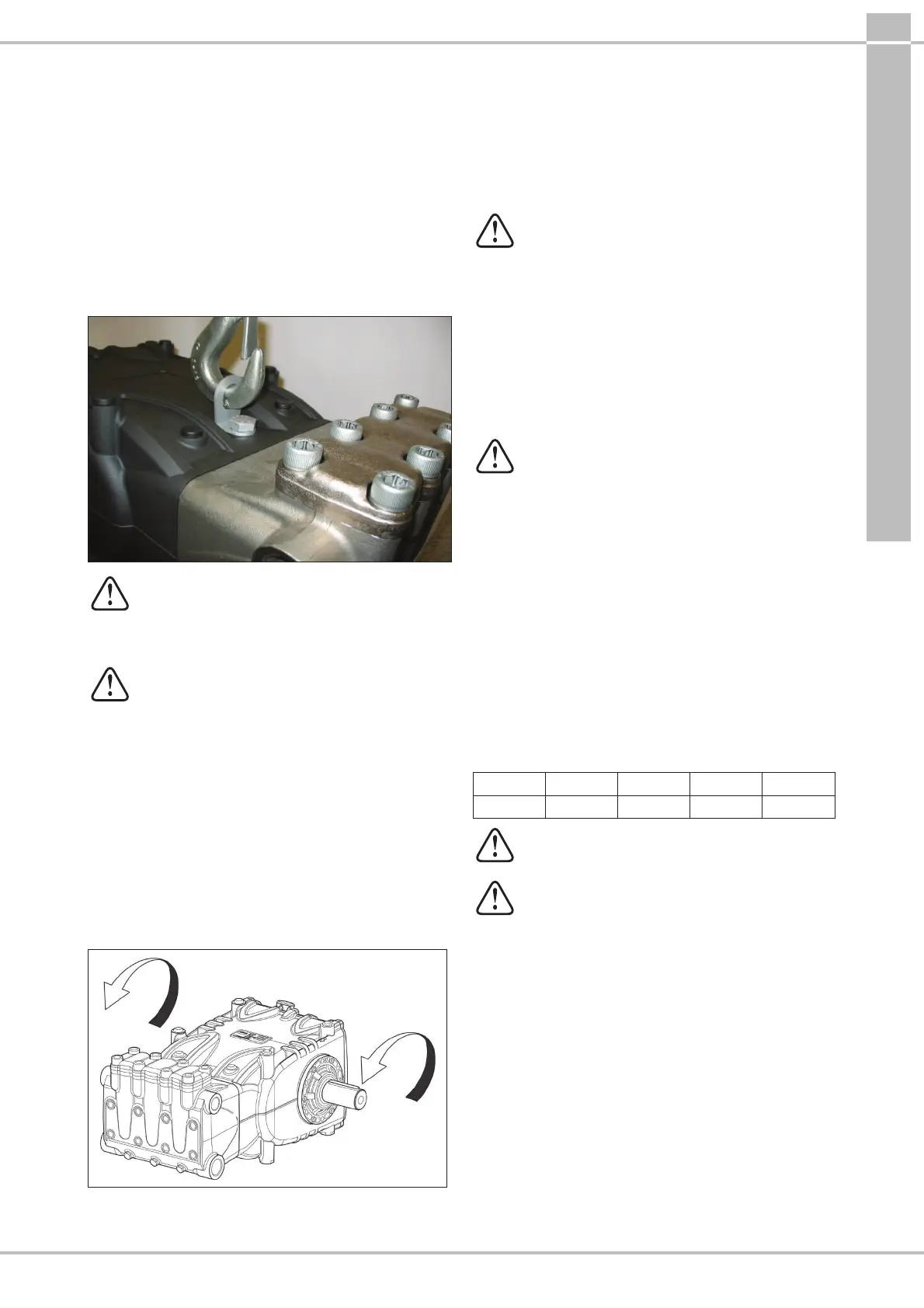

9.2 Rotation direction

The rotation direction is indicated by an arrow located on the

casing near the drive shaft.

From a position facing the pump head, the rotation direction

will be as in Fig.5.

LH SIDE

clockwise

RH SIDE

anticlockwise

Fig.5

9.3 Version change

The pump version is dened as right when:

Observing the pump facing the head side, the pump shaft

must have a PTO shank on the right side.

The pump version is dened as left when:

Observing the pump facing the head side, the pump shaft

must have a PTO shank on the left side.

Note. The version shown in Fig.5 is right.

The version can only be modied by trained and

authorised personnel and carefully following the

instructions below:

1. Separate the hydraulic part from the mechanical

part as indicated in chapter2 par.2.2.1 of the

Repair manual.

2. Turn the mechanical part 180° and reposition

the rear casing cover in such a way that the

oil dipstick is turned upward. Reposition the

lifting bracket and relative hole closing plugs

in the upper part of the casing. Finally, properly

reposition the specication label in its housing

on the casing.

Make sure that the lower casing draining

holes in correspondence with the pistons are

open and not closed from the plastic plugs

provided for the previous version.

3. Unite the hydraulic part to the mechanical part

as indicated in chapter2 par.2.2.5 of the Repair

manual.

9.4 Hydraulic connections

In order to isolate the system from vibrations produced by

the pump, it is advisable to make the rst section of the duct

adjacent to the pump (both suction and outlet) with exible

piping. The consistency of the suction section must be such as

to prevent deformations caused by vacuums produced by the

pump.

9.5 Pump supply

To obtain the best volumetric eciency, feed the pumps with

a positive head (NPSHr).

The recommended value, measured on the head suction

ange, is given in the following table:

HF 18 HF 20 HF 22 HF 25

NPSH

r

(m) 2.5 4.0 4.0 4.5

The values given apply to the rated speed of

rotation; otherwise, contact our Technical or

Customer Service Departments.

For any supply conditions other than those

specied above, contact our Technical or

Customer Service Departments.

Loading...

Loading...