45

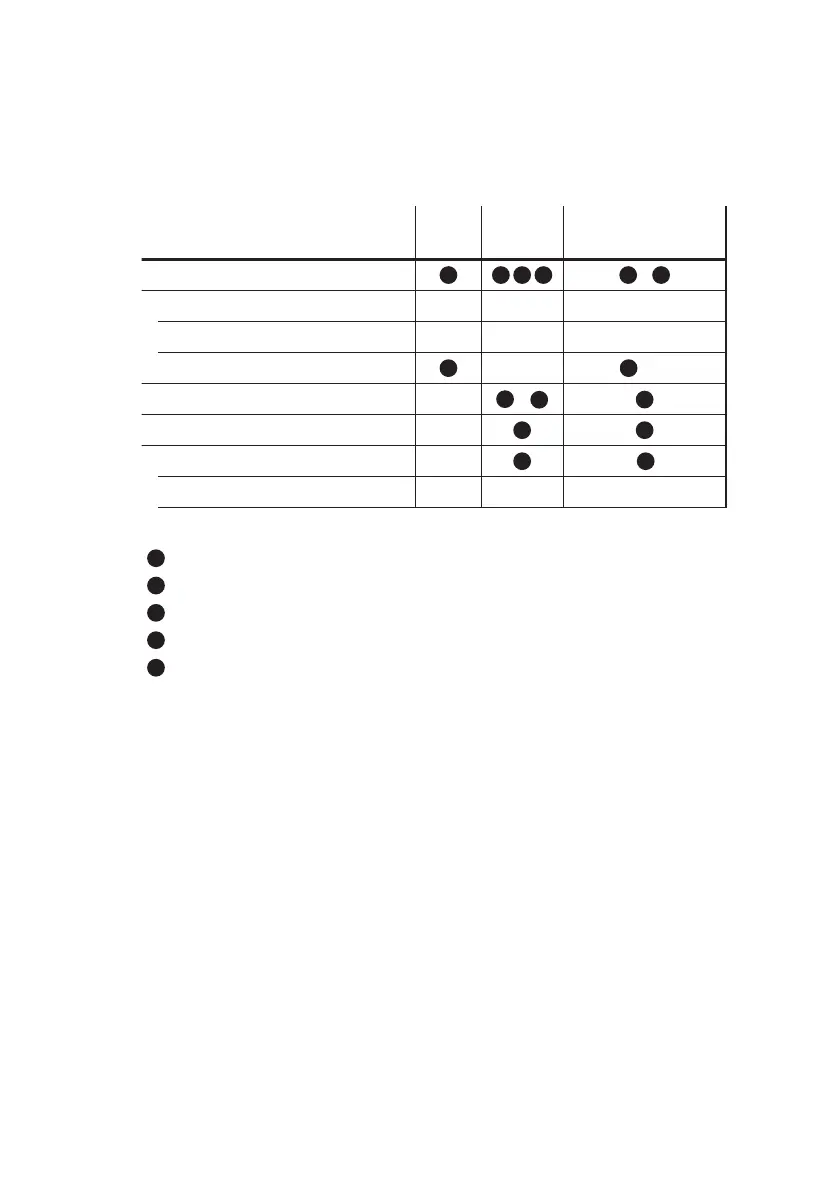

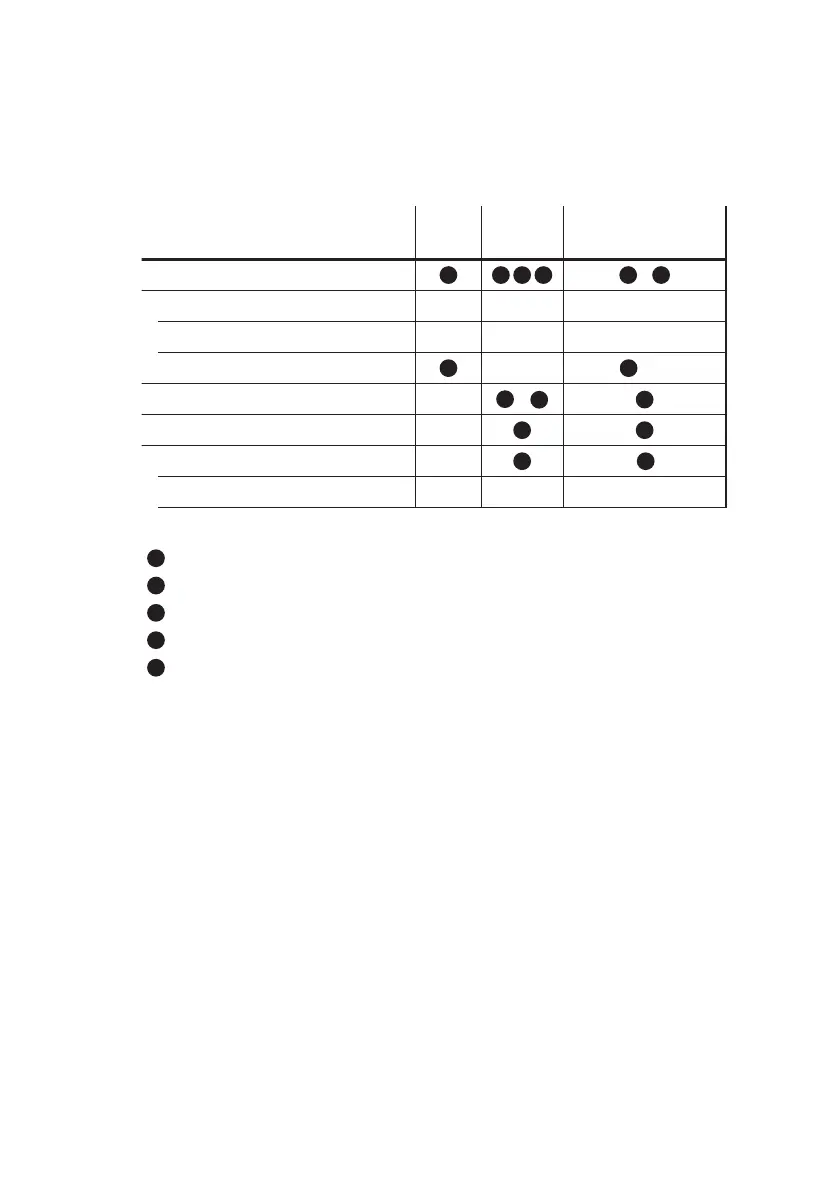

10.5 SERVICE AND TESTING

The below schedule shows the minimum requirements for service and testing as

recommended by Interspiro. Local requirements may differ due to regulations and

environmental conditions. In case of doubt consult your local Interspiro representative.

SERVICE AND TESTING SCHEDULE

This schedule is valid for SCBA equipment.

The schedule shows minimum requirements for service and testing as recommended by Interspiro.

Local requirements may differ due to regulations and environmental conditions.

In case of doubt consult your local Interspiro representative.

I If necessary.

II Environmental conditions and frequency of use

must be considered. Frequent use and/or use in

aggressive environments may lead to shorter

inspection/maintenance intervals.

III Medium pressure hoses older than 15 years

(from date of manufacture) shall not be used.

This requirement is valid also for all accessory

hoses.

U

= Short user test

C

= Cleaning

I

= Inspection

D

= Disinfection

T

= Performance test on calibrated

test equipment

# APPARATUS / COMPONENT

BEFORE

USE

AFTER

USE

EVERY YEAR

1

Breathing Apparatus

U

C

I

U

I

II

T

2

Pressure Regulator & Warning Device

a. Cylinder connection

b. Medium pressure hoses

I

I

II+III

3

Face Mask & Breathing Valve

D

I

I

I

4

Harness

I

I

5

Cylinder / Cylinder Pack

I

I

II

a. Cylinder

Periodic inspection in accordance

with national regulations.

Baserad på

Doc. No. 97307I01

Prior to and after use, perform a visual inspection of all plastic, rubber (elastomeric)

and metal parts for damage. Inspect elastomeric parts for splitting, cracking, or holes.

If any damaged parts are found the SCBA must be taken out of service and repaired

according to the S9 and S9 Incurve Service Manual. Repairs are to be made by

INTERSPIRO or a holder of an INTERSPIRO Service Certicate.

To ensure that your SCBA is working properly a complete test at least once a year

must be performed, even if it has not been used. These tests are carried out on the

SPIROMATIC S test equipment which enables you to test all SPIROMATIC S functions

and identify areas requiring repair.

For SCBAs used daily check cylinder pressure every day.

For SCBAs in storage check cylinder pressure every week.

The short user test before and after use is to be carried out in accordance with the

instructions in this manual.

Loading...

Loading...