Thicknesser

Model DGI-63D

13

CHECKING AND ADJUSTING

BED ROLL HEIGHT

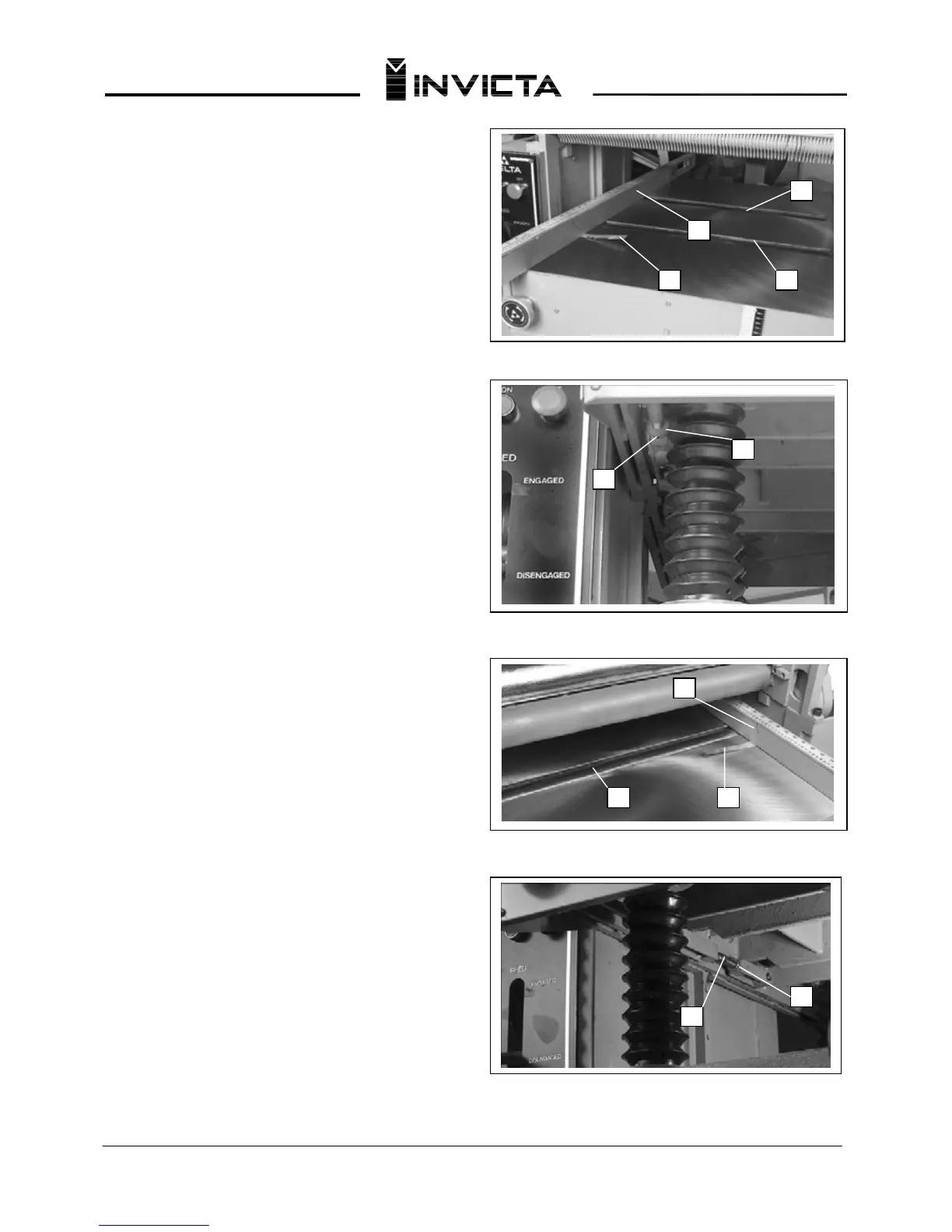

The height of the bed rolls (A) and (E) Fig. 23A, should

be set between .002" and .004" above the table

surfac

e, with the bed rolls at their lowest position. To

check the infeed bed roller height setting, proceed as

follows:

1. DISCO

NNECT MACHINE FROM POWER SOURCE

2. Turn

heig

h

t adju

stment knob

(B), counterclockwi

se

as far as it will go.

3. Place a straight edge (C), across the infeed and

outfeed rollers on the left side of the table as shown.

4. With a fee

ler guage (D), measure the gap between

the table surface and the straight edge (C) ne

ar the

infeed roll (E).

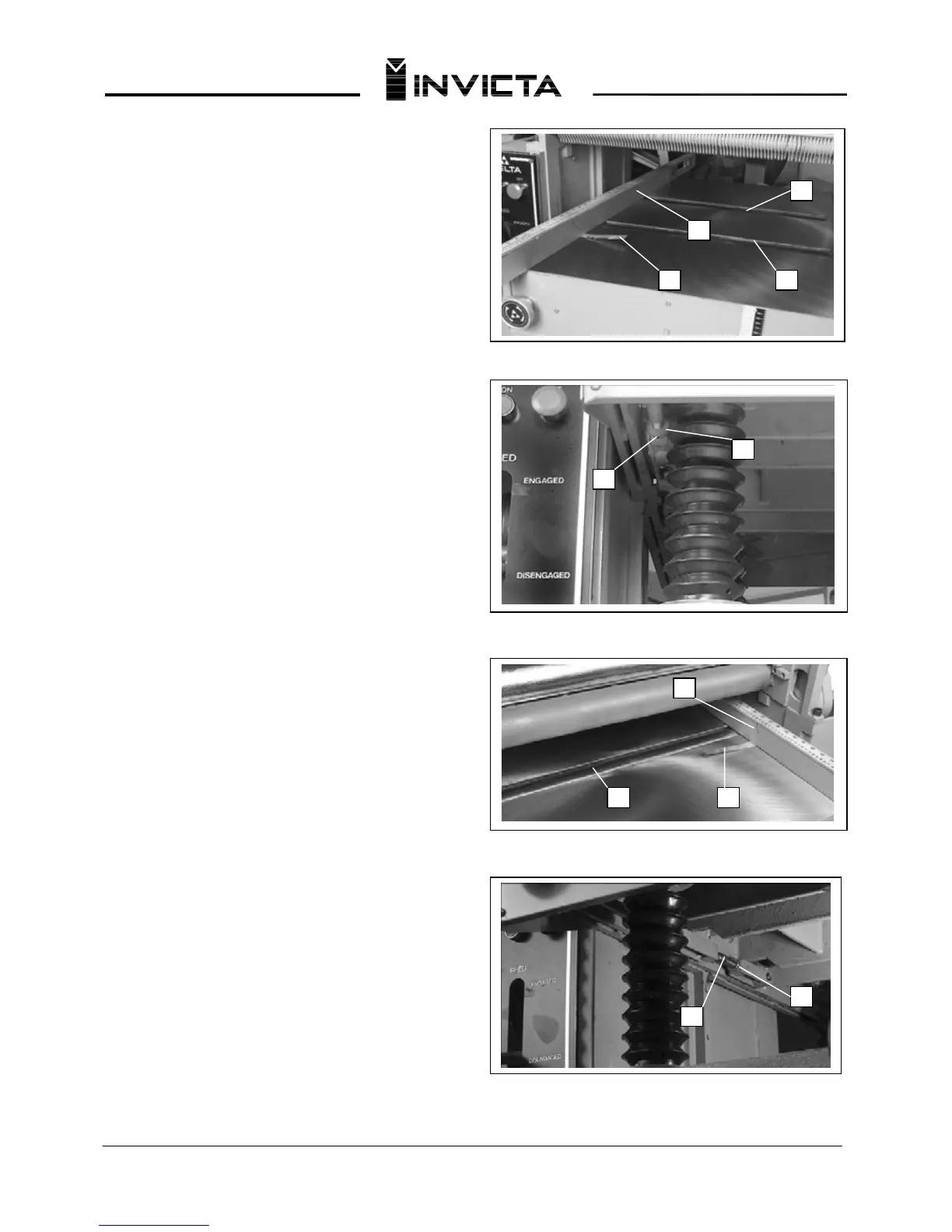

5. If an adjustment to the infeed roller (E), is necessary,

loosen set screw (F) Fig. 23B, located underneath the

left front end of the table.

6. Turn adjustment collar (G) Fig. 23B left or right as

needed to attain proper

height adjustment.

7. Tighten set screw (F) Fig. 23B after adjustment is

made.

To check the outfeed roller height s

etting, proceed

as follows:

1. With a feeler guage (H) Fig. 23C, measure the gap

betwe

en the table surface and the st

raight edge (C)

near the outfeed roller (E).

2. If an adjustment to the outfeed roller is necessary,

loosen jam nut (K) Fig. 23

0, located on the left side of

machine under the table, and turn collar (L) right or left

as needed until the outfeed roller is adjusted properly.

3. Tighten jam nut (K) Fig. 23D.

Fig. 23A

Fig. 23B

Fig. 23C

D

Loading...

Loading...