Thicknesser

Model DGI-63D

14

ADJUSTING PRESSURE BAR

IMPORTANT: THE PRESSURE BAR IS SET AT THE

FACTORY AND SHOULD NOT NEED ASJUSTMENT.

BUT WHEN KNIVES ARE SHARPENED OR

REPLACED THE PRESSURE BAR SETTING

SHOULD BE CHECKED AND ADJUSTED IF

NECESSARY.

The pressure bar is located directly behind the

cutterhead and rides on the plan

ed surface of the stock,

ressing the stock down on the table. If the stock does

not feed, the pressure bar is set too low. If the stock has

chatter marks, the pressure bar is set too high. The

ressure bar must be parallel to the knives and set .040"

below the cutting circle. To check and adjust the

pressure bar, proceed as follows:

1. WARNING DISCONNE

CT MACHINE FROM

POWER SOURCE

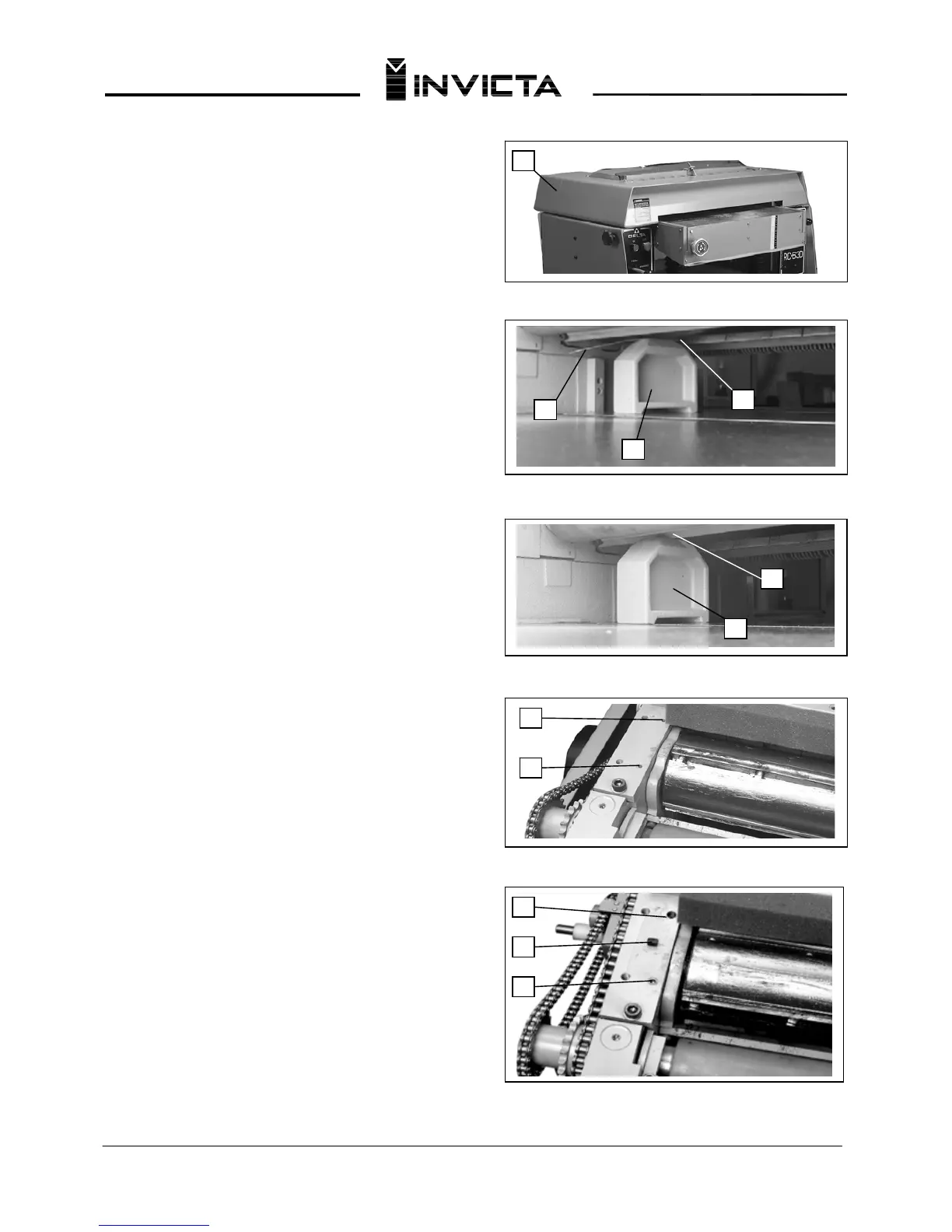

2. Remove the four screws that attach the top cover (A)

Fig. 24A to the planer and carefully remove the top

cover.

3. Make certain the knives a

re adjusted properly as

reviously explained under CHECKING, ADJUSTING

AND REPLACING KNIVES.

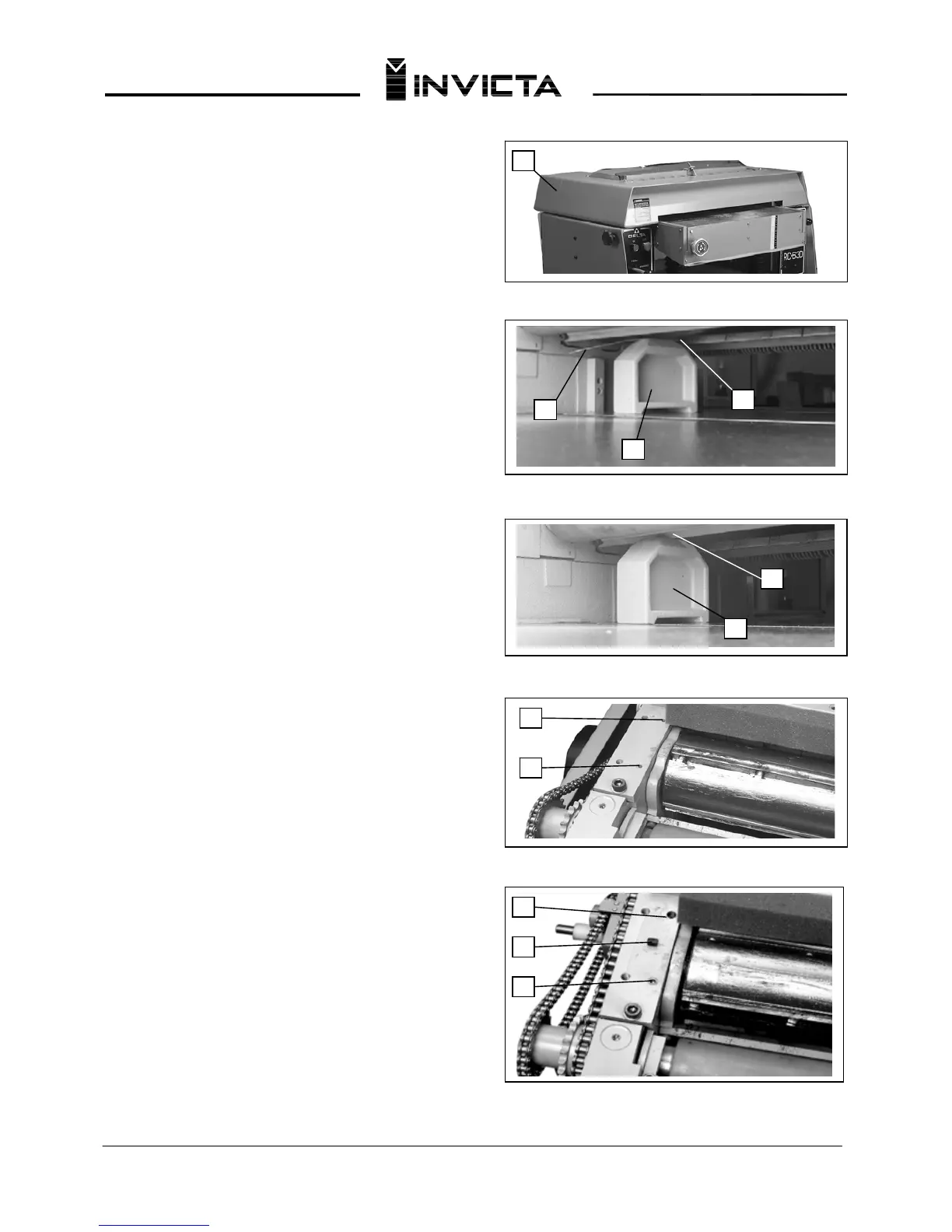

4. Place the guage block (A) Fig. 24B, on the table

directly under

neath the cutterhead as shown. Place a

.040" feeler guage (B) Fig. 24B, on top of the guage

block and raise the table until the knife (C) just touches

the feeler guage when the knife is at its lowest point.

5. Next, set the feeler guage aside and move the guage

block (A) Fig

. 25, directly underneath the pre

ssure bar

(B) on one end of the table. The pressure bar (B) should

ust touch the guage block (A). Check the pressure bar

at the opposite end of the table in the same manner.

6. If the pressure bar must be adjusted, remove screw

(D) Fig. 26. Loosen scre

w (E) Fig. 26A, three or four

turns. Turn screw (F) Fig. 26A clockwise to raise the bar

or counter clockwise to lower the bar. The bottom of

ressure bar should just touch the gauge block (A) Fig.

25.

8. Then tighten screw (E) Fig. 26A until it bottoms and

then loosen it

two complete turns. Replace screw (D)

Fig. 26A.

9. This adjustment to the pressure bar should be made

on the opposite end of the planer In the sam

e manner.

Fig. 24A

Fig. 23B

B

Fig. 25

Fig. 26

D

E

F

D

E

Fig. 26A

Loading...

Loading...