11

ATTENTION: in case of detecting that the water

dispensed did not comply with the national legis-

lation currently in place, redo the measurement.

If the deviation persists, close the equipment entry

valve, empty it through the tap, disconnect it electri-

cally and contact your technical service.

- Finally, clean the inside and bottom of the equipment

with disposable blotting paper in order to remove any

water that may have fallen into the equipment, as this

could cause a false alarm and blockage of the system.

7. MAINTENANCE

ATTENTION: Some components of your equip-

ment, such as pre-filters and membrane, are con-

sumables that have a limited lifespan.

The duration will depend on the quality of the local wa-

ter, usage and specific characteristics of the water to

be treated such as extreme turbidity, high chlorination,

excess iron, etc.

ATTENTION: In order to guarantee the quality of

the water supplied by your equipment, it must be

maintained regularly.

6. LAUNCHING

6.1. RINSING OF FILTER

- It is necessary to remove the dust that the carbon gra-

in of the filter generated during transport and handling

of the equipment and corresponding. This dust must be

removed as it could partially or completely obstruct the

membrane as well as cause a malfunction of the equi-

pment. The equipment will automatically carry out a

washing when the filters are replaced.

6.2. SANITIZATION OF THE EQUIPMENT

- Sanitize the equipment according to the model and

8

10

11 12

9

13

procedure indicated by the manufacturer (see Sanitiza-

tion Procedure). If in doubt, consult your dealer.

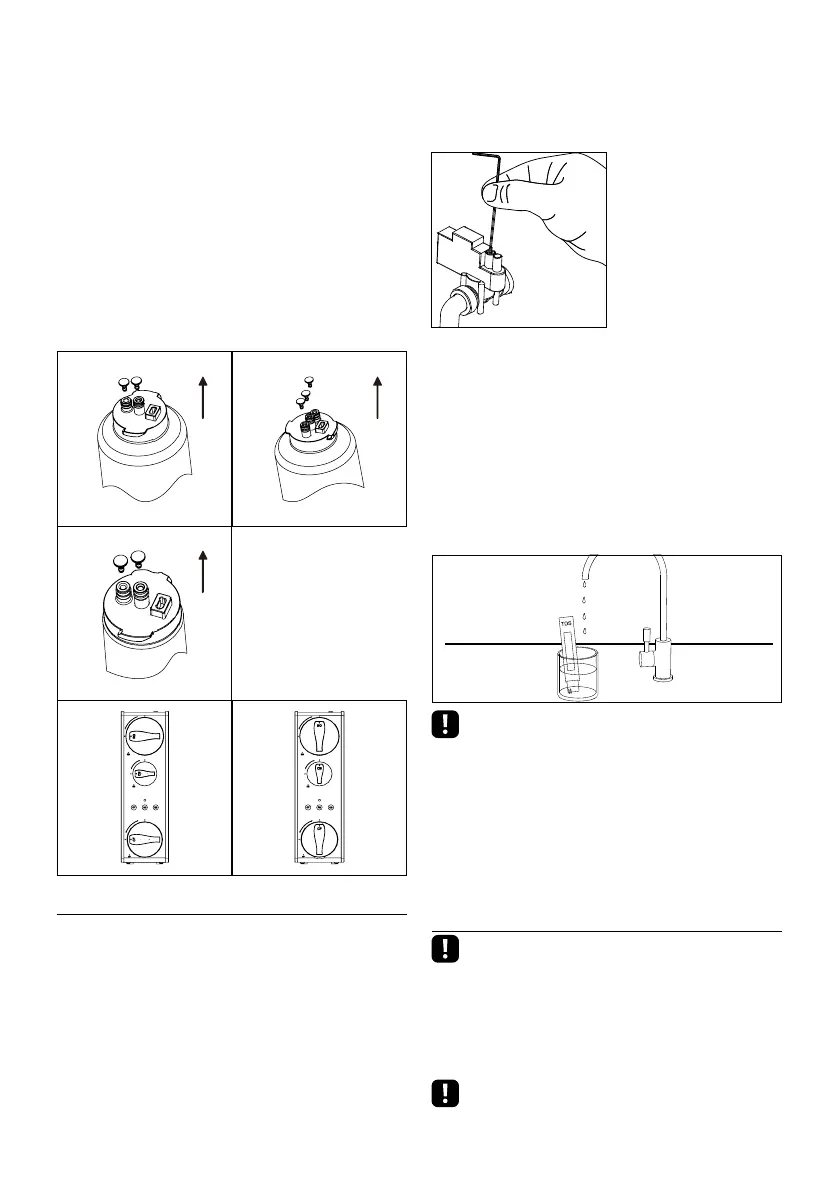

6.3. SEALING THE SYSTEM, SHUTDOWN AND START-UP

- Close the equipment faucet on the worktop and keep

the equipment hydrau-

lically or electrically su-

pplied by carrying out an

eye check of the system

to ensure that there is no

leakage (for approx.).

- If the equipment pump

does not stop, adjust the

tare weight of the maxi-

mum pressure switch with

an Allen key 2, until the pump (13) stops.

Open the dispenser tap. The equipment should be ac-

tivated and water supplied. Turn off the tap again and

check that the equipment stops.

6.4. RINSING AND CLEANING

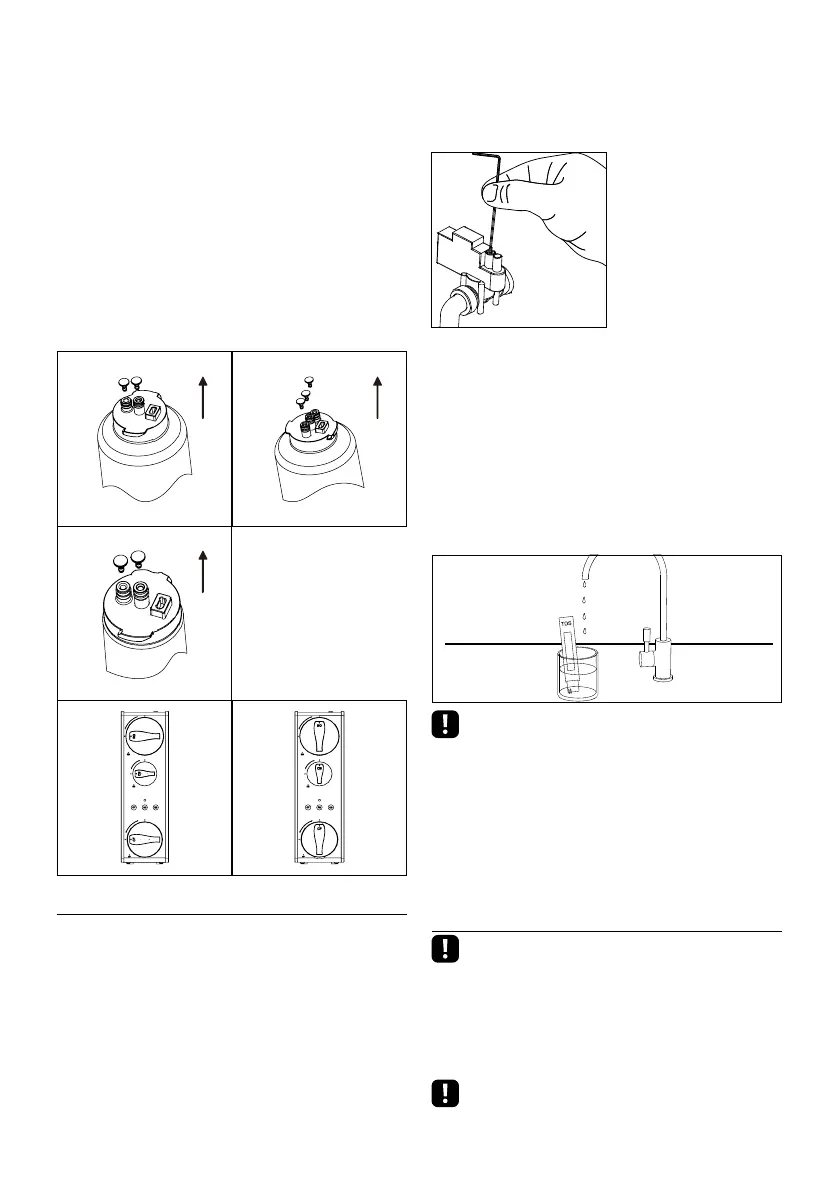

- Open the faucet and measure the quality of the wa-

ter being produced. With a conductivity meter or TDS,

check that the reduction in salts obtained is adequate

with respect to the water to be treated (14).

14

CF

CB

CB CB

RO RO

CF CF

RO

5.2. INSTALLATION OF FILTERS

- Remove the rubber plugs on the pre-filter (CF), membrane

(RO) and post-filter (CB) water intakes as shown in Figures

8, 9 and 10.

- Install the CF filter in the first stage of the LATT machine

(lower position), the RO membrane in the second stage of

the LATT machine (upper position) and the CB post-filter in

the third stage of the LATT machine (middle position).

- To install the filters, present each filter in its respective

housing with the handle in horizontal position, as shown in

figure 11.

- Insert firmly until the end and turn the handle 90 degrees

clockwise. After installation, the three filters should remain

as shown in Figure 12.

Loading...

Loading...