Ficha técnica

*

For salinity higher than 1500ppm consult your dis-

tributor.

** Higher hardnesses may shorten the life and func-

tion of certain components.

*** Maximum accumulation as a function of inlet

pressure.

**** Flow rates may vary by 20% depending on the

temperature, pressure and specific composition of

the water to be treated.

***** May vary depending on model.

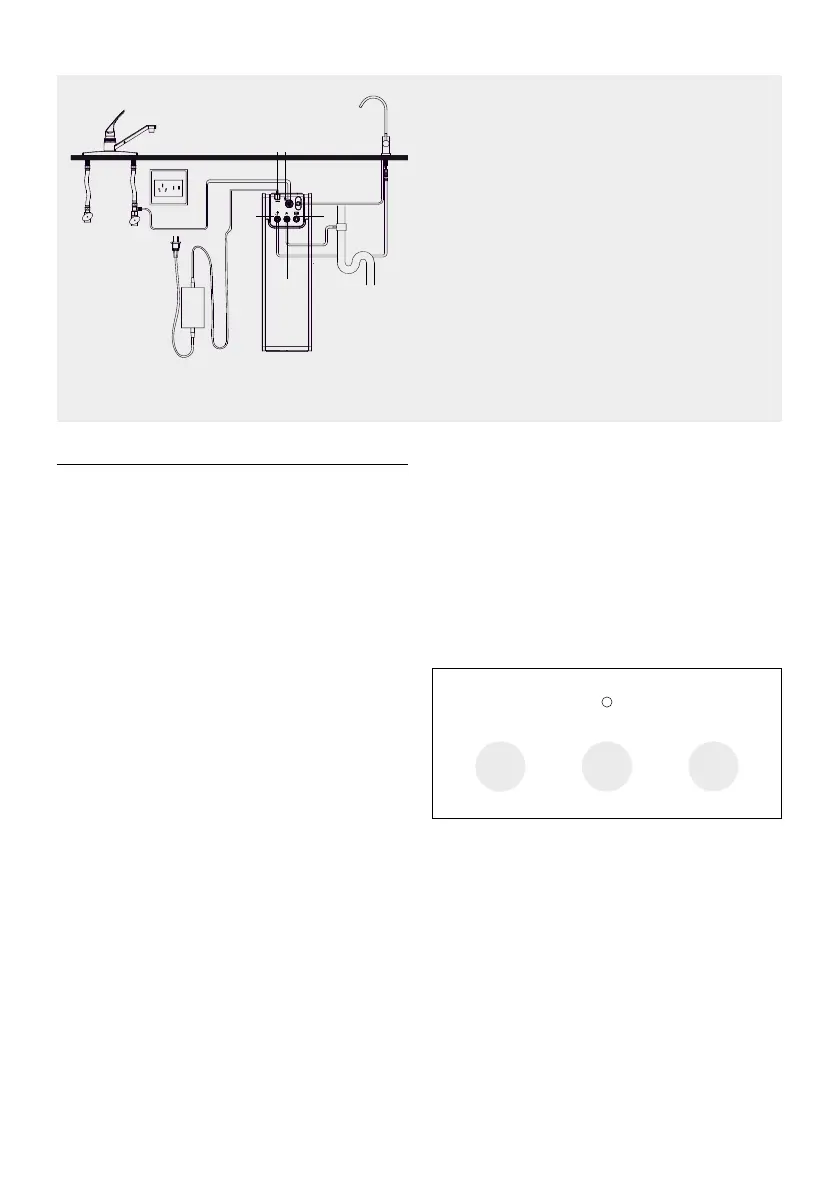

HYDRAULIC WIRING DIAGRAM

2. OPERATION OF THE EQUIPMENT

- The mains water to be treated enters the equipment

through the pre-filtration stage which features a GAC

(CF) turbidity and carbon filter. In this filtration stage,

suspended particles, chlorine, its derivatives and other

organic substances are retained.

- The unit features a minimum pressure switch to pro-

tect the pump against pressure drops in the network

(LPS).

- The flow of water into the equipment is controlled by

a solenoid shut-off valve (Si).

- The water, after being treated in the filtration stage,

is pushed towards the reverse osmosis (RO) membrane.

The equipment incorporates a pump (P) to increase the

pressure. The pressure of the water on the membrane

makes the reverse osmosis process possible.

- Before going out through the tap, the water passes

through the post-charcoal filter, which improves the

taste.

- Rejected water or water containing excess salts and

other dissolved substances is directed to the drain for

disposal.

- The direct flow equipment controls the start and stop

by means of a pressure switch (HPS).

- The equipment incorporates different functional and/

or security systems, managed by a state-of-the-art

electronic module:

- Electronic leak detection system (L). When the system

detects this situation, it blocks the equipment emitting

an acoustic and luminous signal informing about it. The

equipment will remain blocked until the detection pro-

be is dry.

- Probe for estimating the conductivity of the water

produced to evaluate the condition of the membrane

and components (Q). When water is dispensed through

the tap, the system will measure the conductivity of the

water produced.

- Automatic filter change warning, in order to inform

the user that proper maintenance must be carried out

to guarantee the quality of the water dispensed.

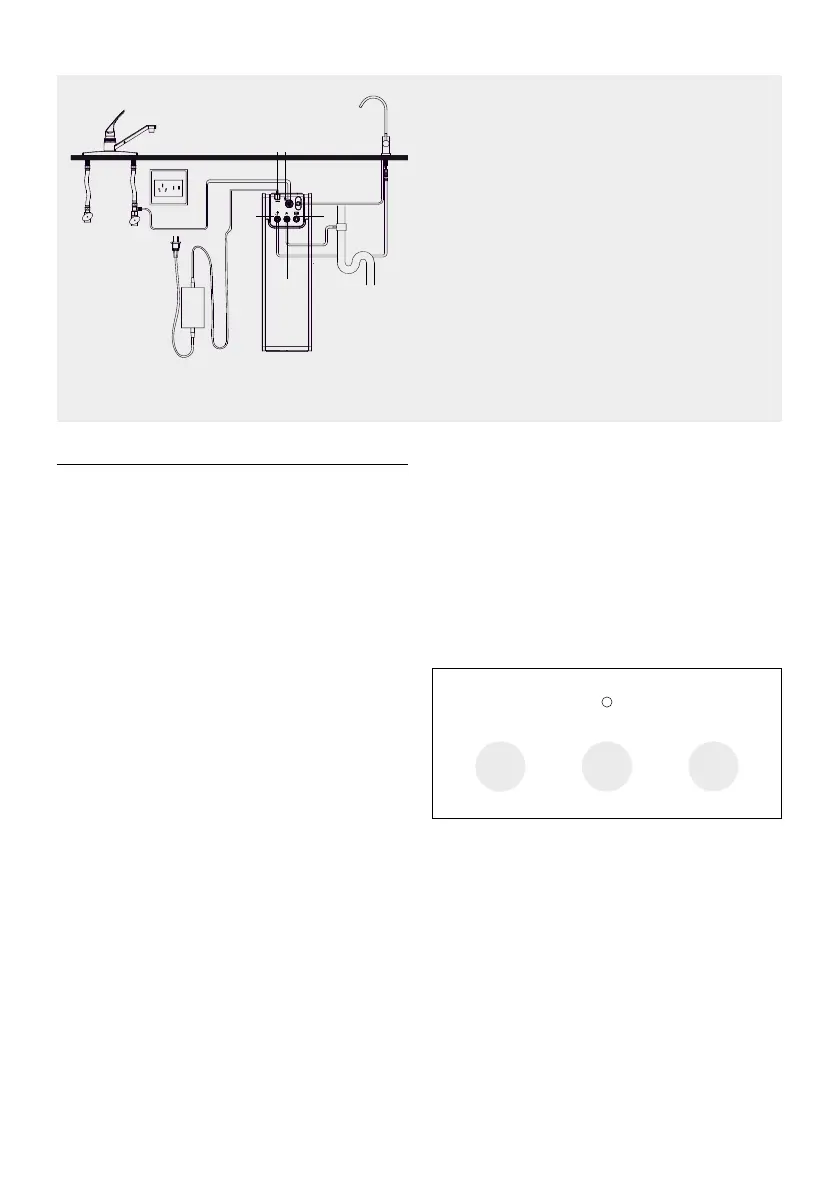

3. INTERFACE. STATE OF THE SYSTEM

Display

3.1 WATER QUALITY INDICATOR COLORS

- Blue: TDS≤100ppm

- Lilac: 100ppm < TDS ≤ 150ppm

- Red: TDS > 150ppm

CF RO CB

Indicador de calidad del agua o fallo

Indicadores / pulsadores de vida de los filtros

1. Interfaz de datos

2. Desagüe

3. Grifo

4. Entrada

5. “Power”

1

2

3

4 5

Loading...

Loading...