9

- This equipment should not be installed either lying

down or tilted (2), because the leakage sensor would

become disabled.

If the equipment is full of water, the distribution of

weights in an unforeseen position could cause some

connecting element to be forced, which could cause

malfunction, damage to components of the equipment

or loss of water.

- The installation site must have sufficient space for the

appliance itself, its accessories, connections and for

convenient maintenance (3).

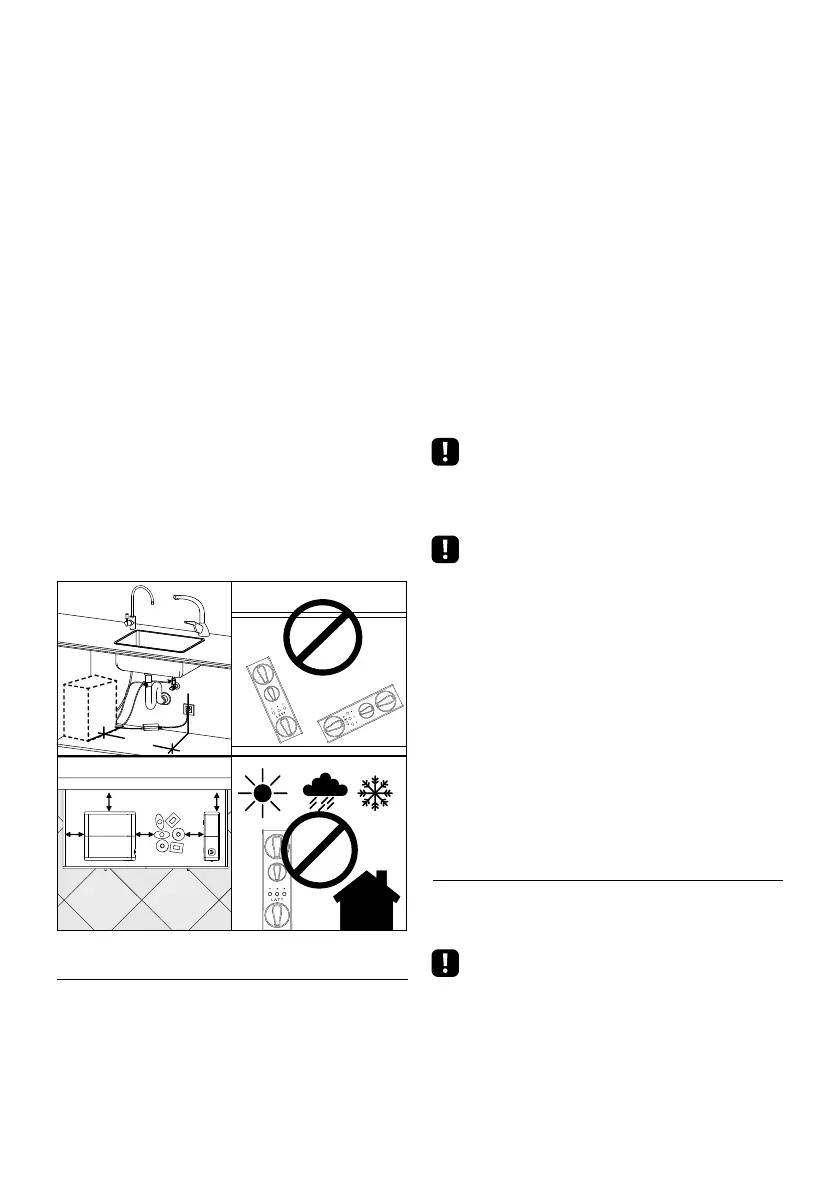

- Under no circumstances should the equipment be ins-

talled outdoors (4).

- The environment in which equipment and taps are

installed must have adequate hygienic-sanitary condi-

tions.

-Avoid external dripping on the equipment from pipes,

drains, etc.

ATTENTION: The equipment must not be installed

next to a heat source or directly receiving a flow of

hot air over it (dryer, refrigerator, etc.).

3.1. STARTING UP AND MAINTENANCE

ATTENTION: Water treatment plants requires re-

gular maintenance by qualified technical person-

nel in order to guarantee the quality of the water

produced and supplied.

- The consumable elements must be changed at the

time indicated by the manufacturer.

- The equipment must be sanitized periodically and be-

fore starting up.

- After putting it into use, discard any water that is pro-

duces during the first 30 minutes of use.

- Maintenance must be carried out by qualified tech-

nical personnel, with proper care and hygienic condi-

tions, in order to reduce the risk of internal contamina-

tion of the appliance and its hydraulic system. (For more

information contact your dealer’s technical service).

4. UNPACKING

Before installation and start-up, it is important to check

the box and condition of the equipment to ensure that

it has not been damaged in transit.

ATTENTION: Claims for damage during transport

must be presented together with the delivery note

or invoice to your distributor, attaching the name of

the carrier within a maximum of 24 hours after receipt

of the goods.

Remove the equipment and accessories from their car-

dboard packaging, removing the corresponding protec-

tions.

- If the water to be treated has a hardness greater than 15

ºHF, this could lead to a reduction in the life of the membra-

ne and in the performance of the equipment.

- In case the water contains a concentration higher than

1.2 ppm of total chlorine, it is recommended the installa-

tion of an active carbon dechlorination filter to reduce the

concentration of chlorine in the water and thus protect and

extend the life of the equipment components.

in cases where the water to be treated contains:

High concentrations of iron and man-

goose (Greater than 1ppm measured at rejection)

of the machine).

Prolonged hyperclorations over time.

Sludge or turbidity greater than 3 NTUs.

A nitrate concentration higher than 100 ppm.

A concentration of sulfates higher than 250 ppm.

- Contact your distributor for advice on the most suitable

pre-treatment for your case, in order to ensure proper ope-

ration of the equipment, avoid damage to components and

ensure the quality of the water supplied.

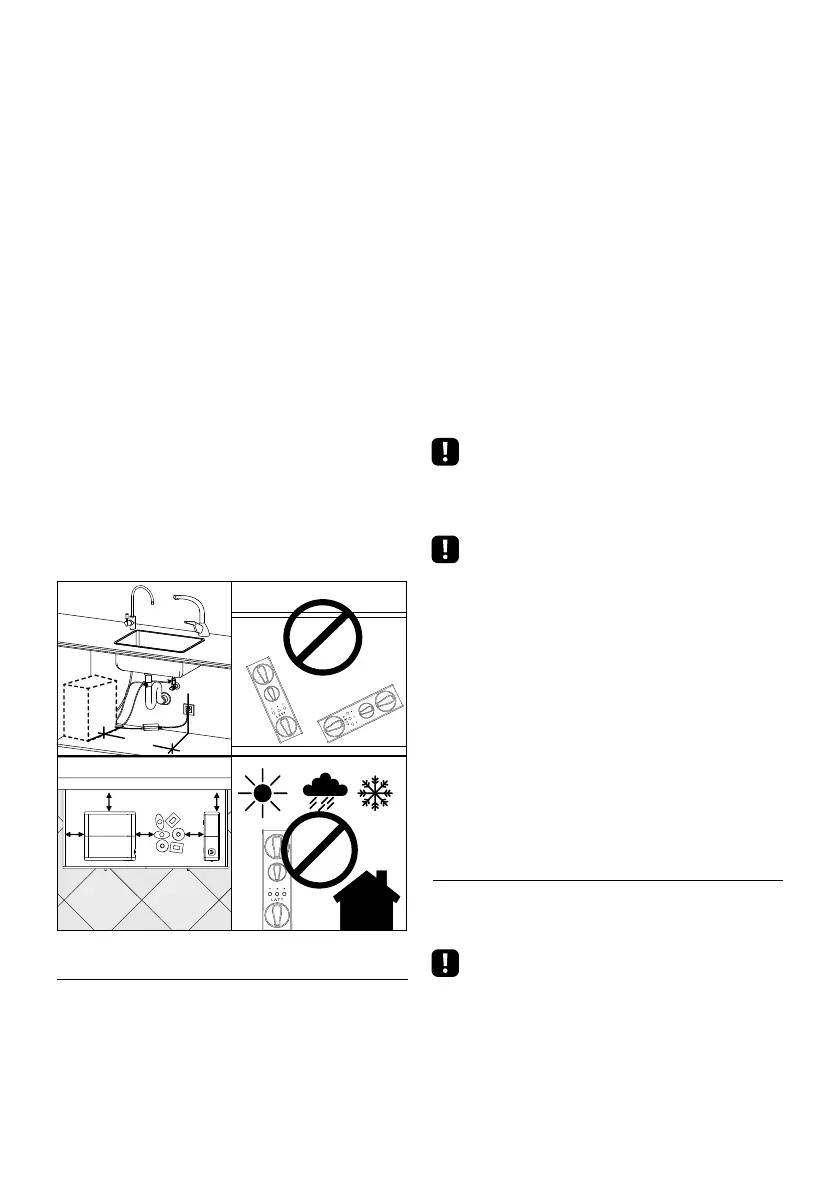

3. INSTALLING THE EQUIPMENT

- If the installation of the housing needs to be conditio-

ned in order to be able to install the equipment in the

planned location, this must be done in accordance with

national standards for interior installations of water and

electricity supplies.

- This equipment needs an electrical socket at a distan-

ce of less than 1 metre (1).

1

1 m

3

2

4

Loading...

Loading...