(1) Adjust the timing between the needle and the hook as follow:

1) Turn the hand wheel to bring the needle bar down to the lowest point of its stroke,and loosen

setscrew.

* Adjusting the needle bar height

2) Pull the needle bar,you can see the pinhole basset 1/2 level through edge of inside hook(needle must

be position). Turn needle cover wire slot left,then tighten setscrew.

* Adjusting position a of the hook

3)First move the point of hook in direction, when running strap pulley needle bar risen from the

lowest,Observe cooperate relation of the hook and needle.When hook point above Pinhole about

top of 1mm to 1.5mm and when plane of the hook point form plane of needle short bar 0.05mm(keep the

align hook blade point with the center of needle),tighten the hook setscrews.

注意

若间隙太小,会磨损梭尖,若间隙太大,则会引起跳针;

旋梭原来用的什么型号,调换后,也请使用原来的型号;

更换机针后注意机针必须安装到位且类型相同,如不同类型机针须检查配合关系。

*Precaution

If the clearance is too small,the tip of the hook will be abraded.

If it is too big,it will lead to skip over.

*Note that the type of hook to be substituted for,when replacing the hook.Shall be in

conformity with the very type of the hook installed in the sewing machine of original

assemblage.

After replacing the needle.the needle must be same type and install right position.If the

needle is different type need check match with relation.

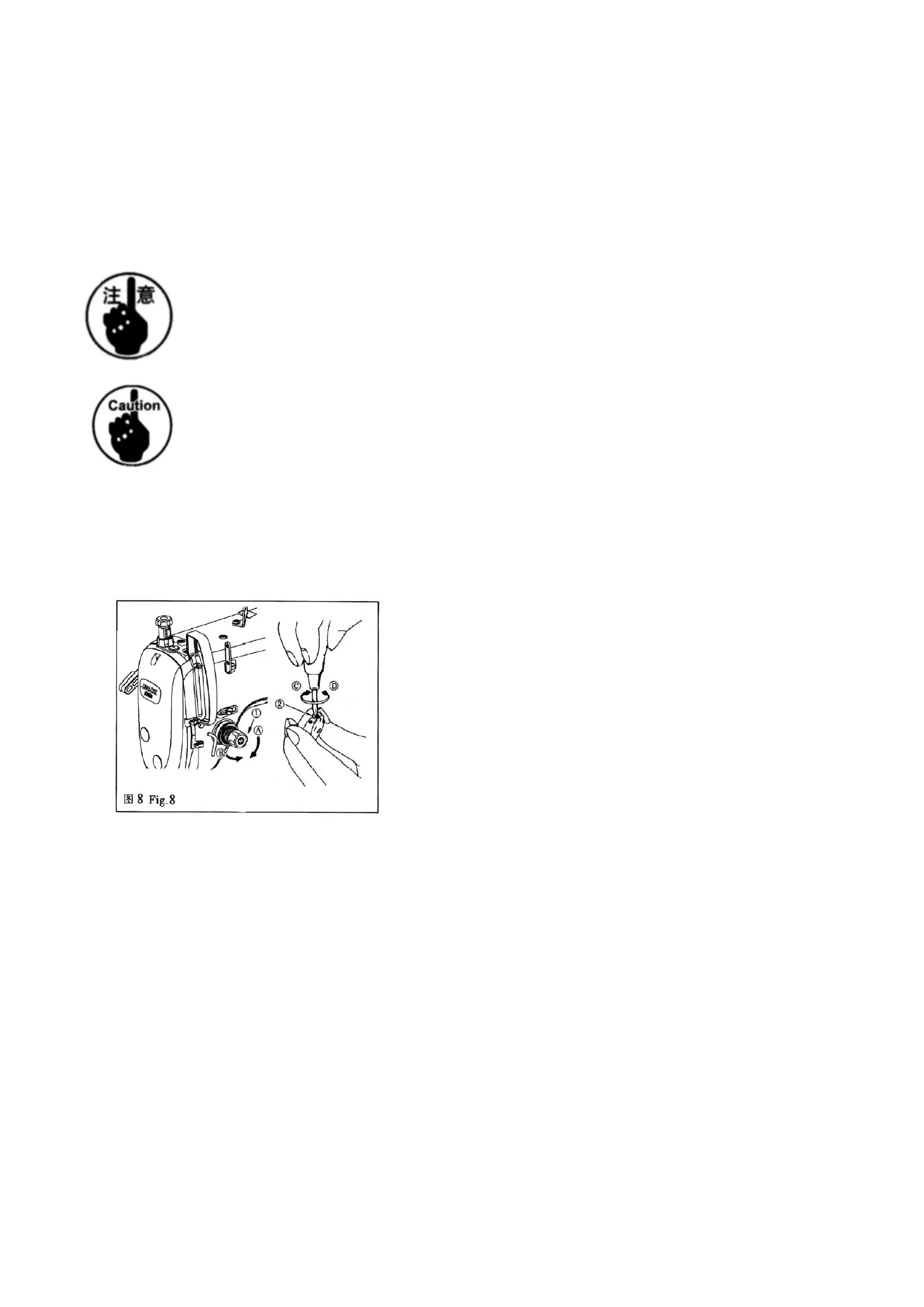

(1)Adjusting the needle thread tension

1)Adjust the needle thread tension using tension ad just nut ① according to the sewing specifications.

2)As you turn nut ① clockwise(in direction A),the needle thread tension will increase.

3)As you turn nut ① counterclockwise(in direction B),the tension will decrease.

(2)Adjusting the bobbin thread tension

1) As you turn tension adjust screw ② clockwise(indirection C),the bobbin thread tension will

increase.

2)As you run screw ② counterclockwise(in direction D),the bobbin thread tension will decrease.

Loading...

Loading...