8

INSTALLATION MANUAL FOR 490A

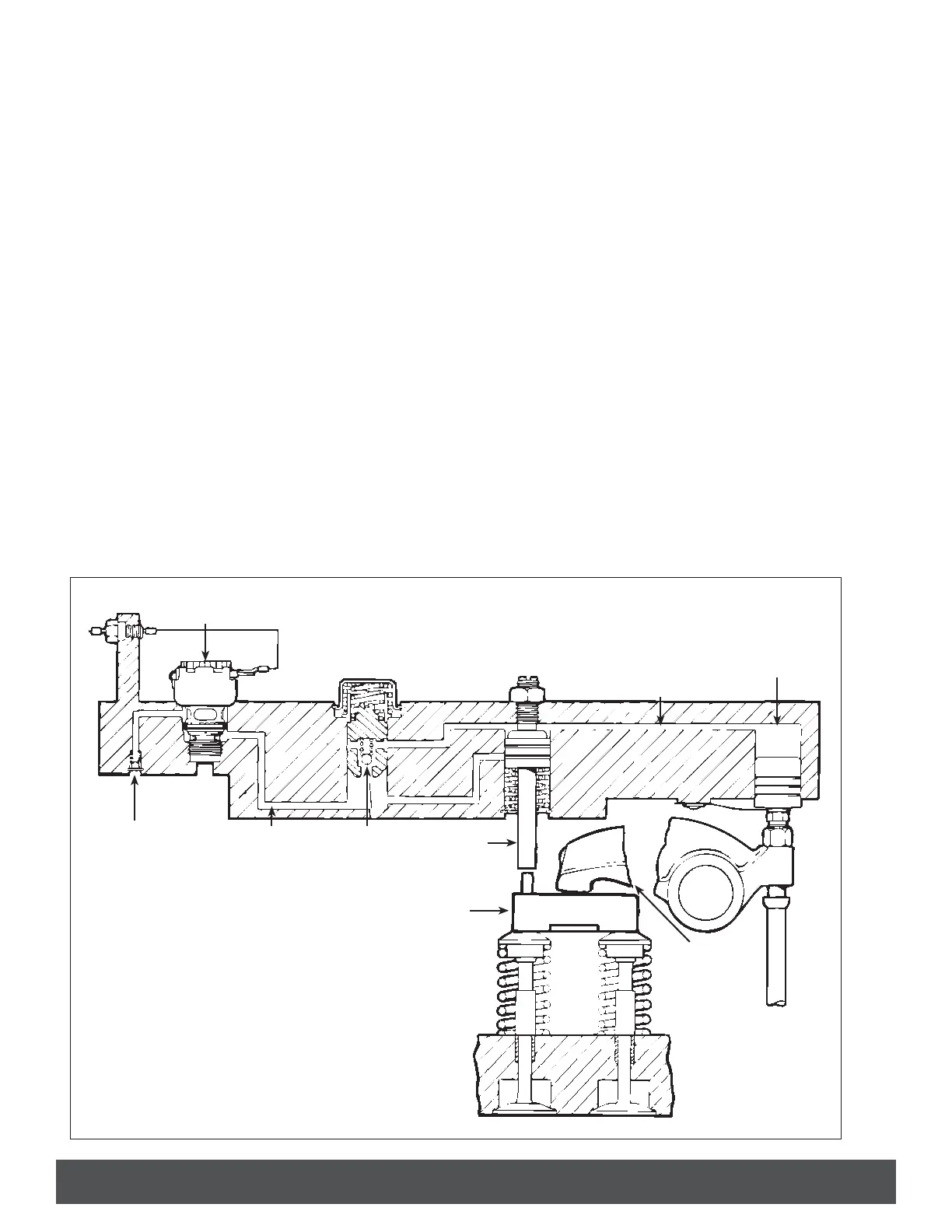

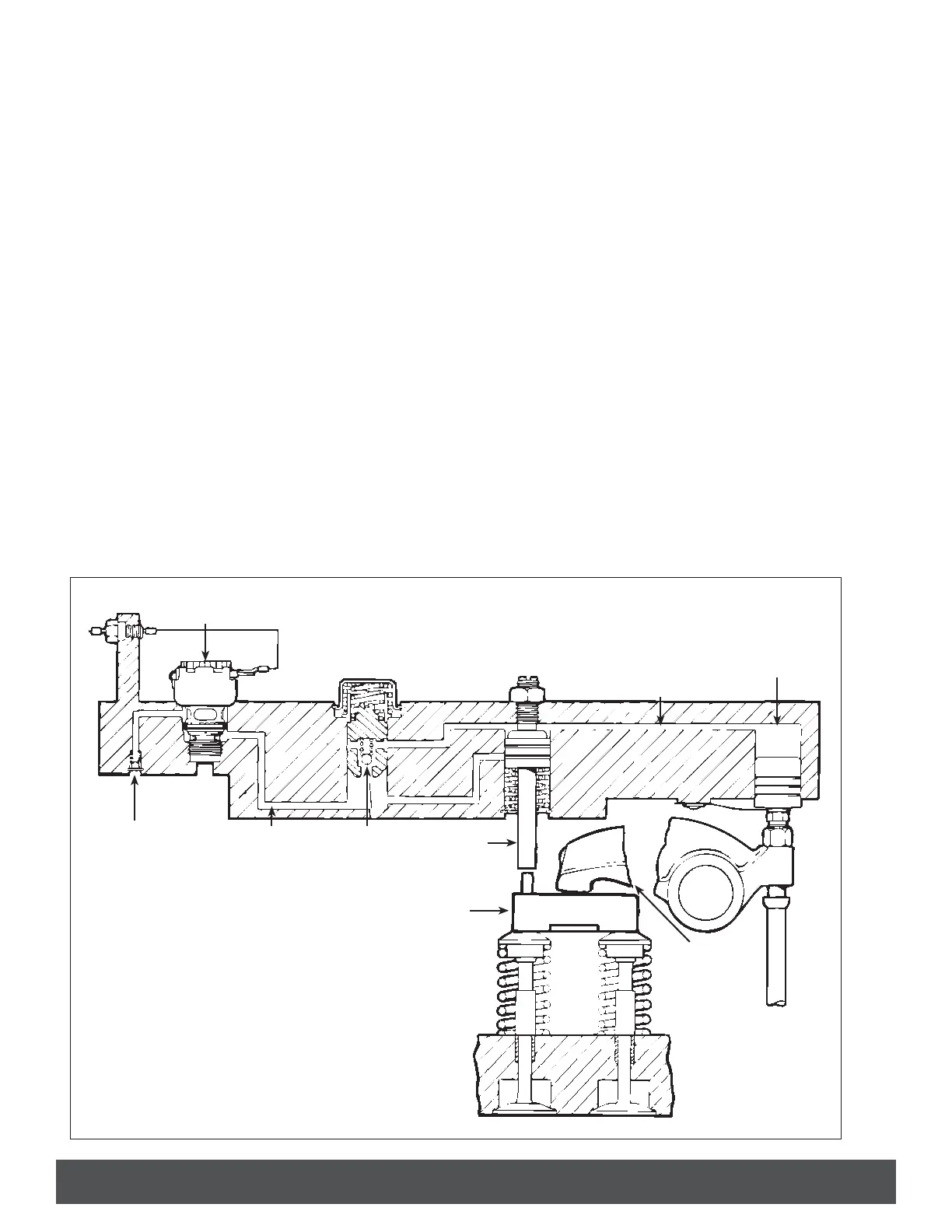

Section 6: Brake Maintenance

Theory of Operation

Energizing the engine brake effectively converts

a power-producing diesel engine into a pow-

er-absorbing air compressor. This is accomplished

through motion transfer using a master/slave

piston arrangement which opens cylinder exhaust

valves near the top of the normal compression

stroke, releasing the compressed cylinder charge

to exhaust.

The blowdown of compressed air to atmospher-

ic pressure prevents the return of energy to the

engine piston on the expansion stroke. The effect

is a net energy loss, since the work done in com-

pressing the cylinder charge is not returned during

the expansion process.

Exhaust Blowdown

Referring to Fig. 11, exhaust blowdown occurs as

follows:

1. The energized solenoid valve permits engine

lube oil to flow under pressure through the

control valve to both the master piston and the

slave piston.

2. Oil pressure causes the master piston to move

down, coming to rest on the exhaust rocker

arm adjusting screw.

3. The exhaust rocker arm adjusting screw begins

upward travel (as in normal exhaust cycle),

forcing the master piston upward and direct-

ing high pressure oil to the slave piston. The

ball check valve in the control valve imprisons

high-pressure oil in the master/slave piston

system.

4. The slave piston, under the influence of the

high-pressure oil moves down, momentarily

opens one exhaust valve while the engine

piston is near its top dead-center position, re-

leasing compressed cylinder air to the exhaust

manifold.

5. Compressed air escapes out to the atmo-

sphere, completing a compression braking

cycle.

FIG. 11

OIL IN

SOLENOID

VALVE

CONTROL

VALVE

ADJUSTING

SCREW

HIGH

PRESSURE

OIL

MASTER

PISTON

EXHAUST

PUSHROD

SLAVE

PISTON

BALL

CHECK

VALVE

EXHAUST VALVES

EXHAUST

ROCKER

LEVER

GUIDELESS

CROSSHEAD

LOW

PRESSURE

OIL

Loading...

Loading...