11

Solenoid Valve

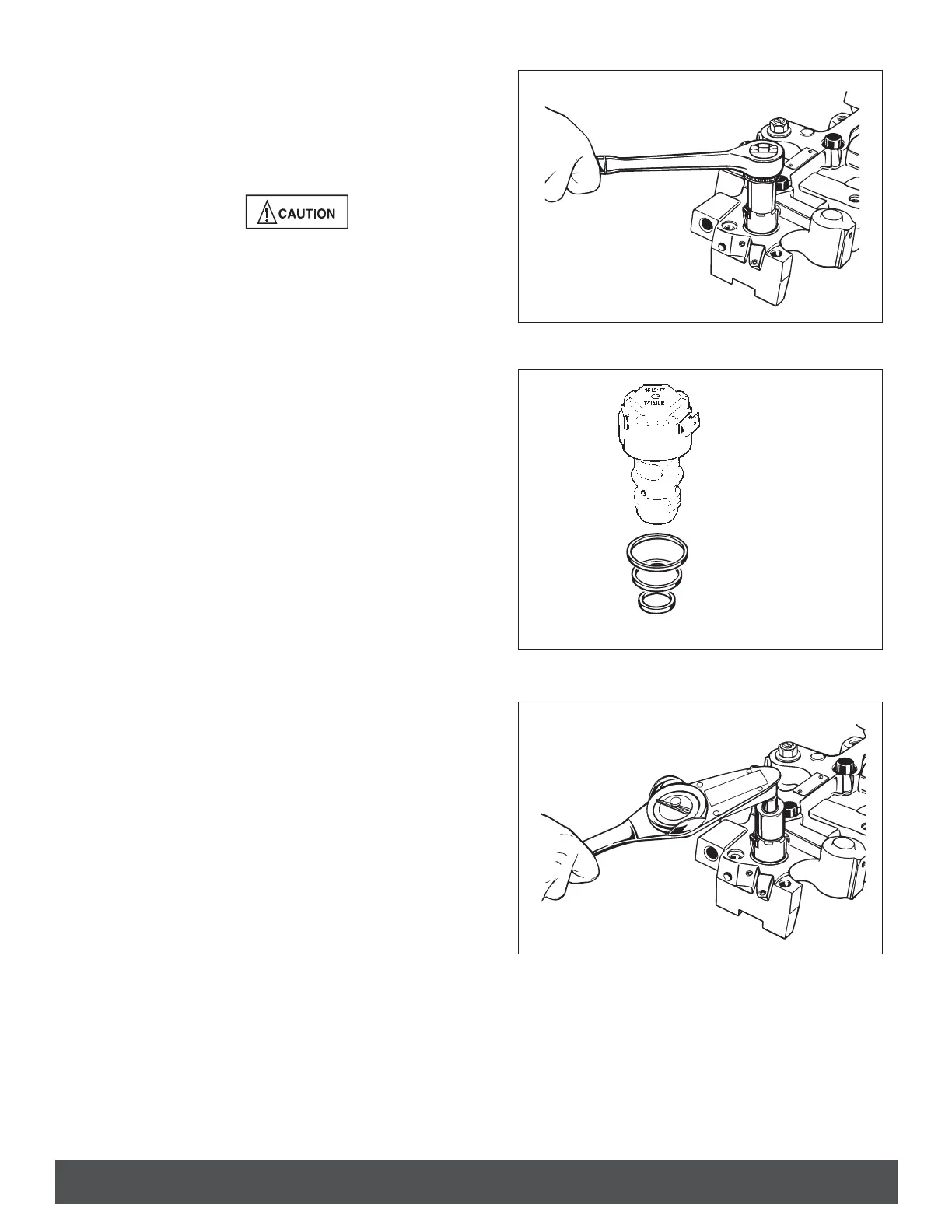

1. Disconnect the solenoid harness. Using a 3/4”

socket and extension, unscrew the solenoid

valve (see Fig. 17).

DO NOT DISASSEMBLE OR TAMPER WITH

THE SOLENOID VALVE. ENGINE DAMAGE

COULD RESULT.

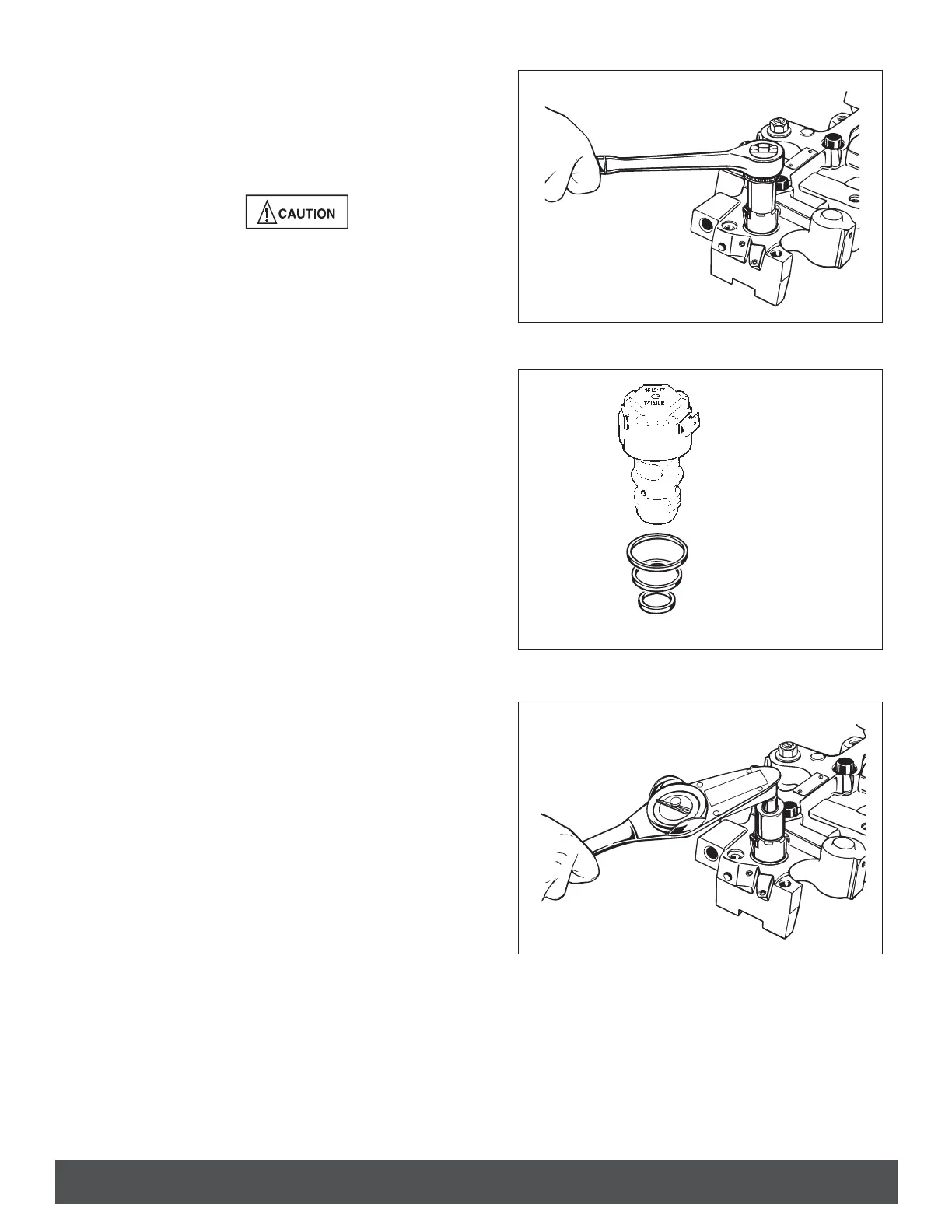

2. Remove and discard the rubber seal rings (Fig.

18). If the lower ring stays in the bottom of the

housing solenoid bore, remove with a seal pick.

3. Wash out the solenoid valve with approved

cleaning solvent. Use a brush to clean the

oil screen. Clean and dry the valve with com-

pressed air. Replace oil screen, if necessary.

4. Clean out the solenoid valve bore in the hous-

ing. Use clean paper towels. Never use rags, as

they may leave lint and residue which can plug

the oil passageways.

5. Reinstall the solenoid using new seal rings.

Seat lower seal ring (ISL only) in the base of

the solenoid valve bore. Wipe clean lube oil into

and around the bore. Place upper and center

seal rings on the solenoid valve body.

6. Be sure the seals are seated properly and

carefully and screw the solenoid into the hous-

ing without unseating the seals. Torque the

valve to 20 N•m [15 lb.-ft] (see Fig. 19).

FIG. 19

FIG. 18

FIG. 17

Note: 490A only has two seal rings.

UPPER SEAL

LOWER SEAL

Loading...

Loading...