Page 7Jandy

®

Filters

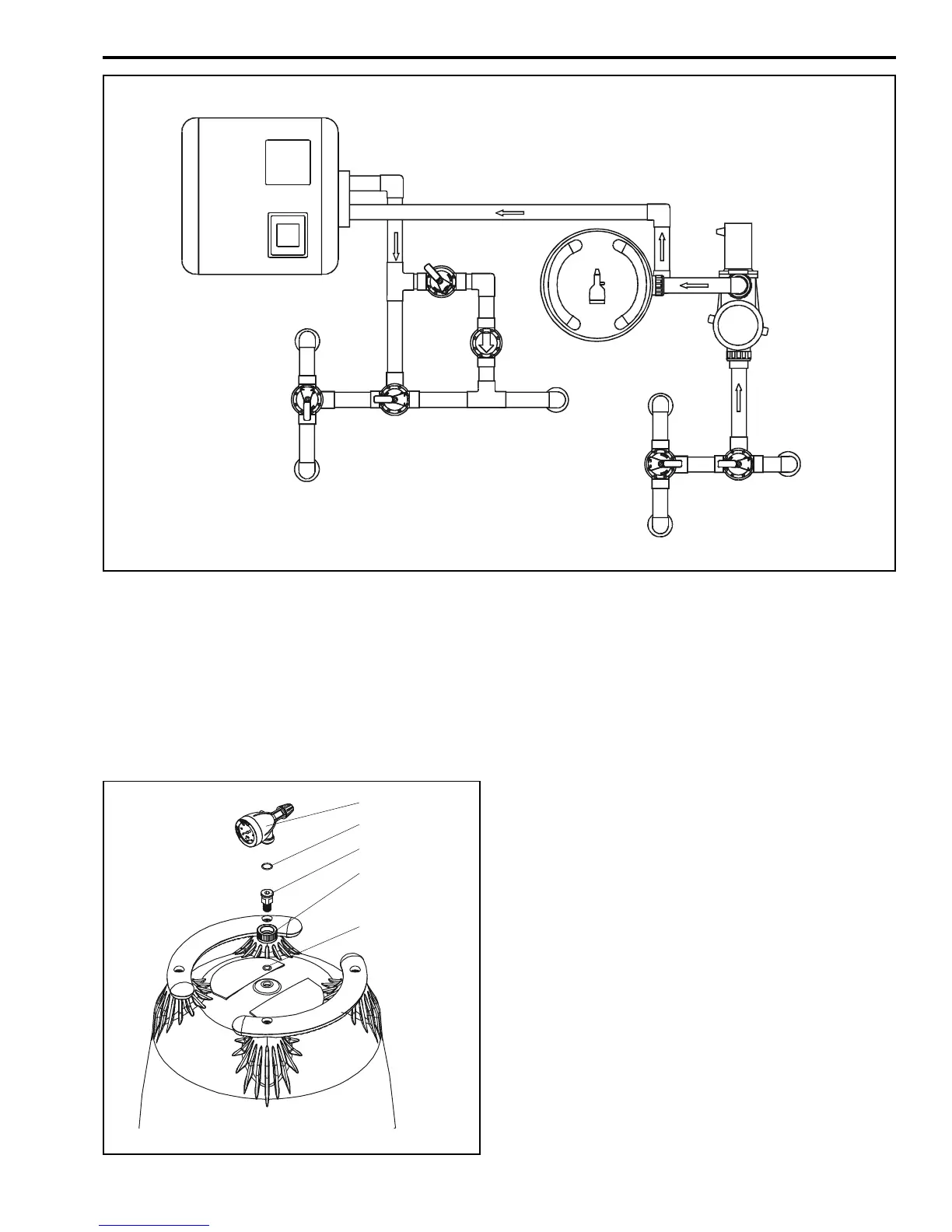

c. Orient the gauge/air release assembly in the

desired position. Raise and thread the locknut

onto the bottom of the gauge/air release assembly.

Hand tighten the nut only. Using a wrench to

tighten the nut may damage the nut, gauge or

air release assembly.

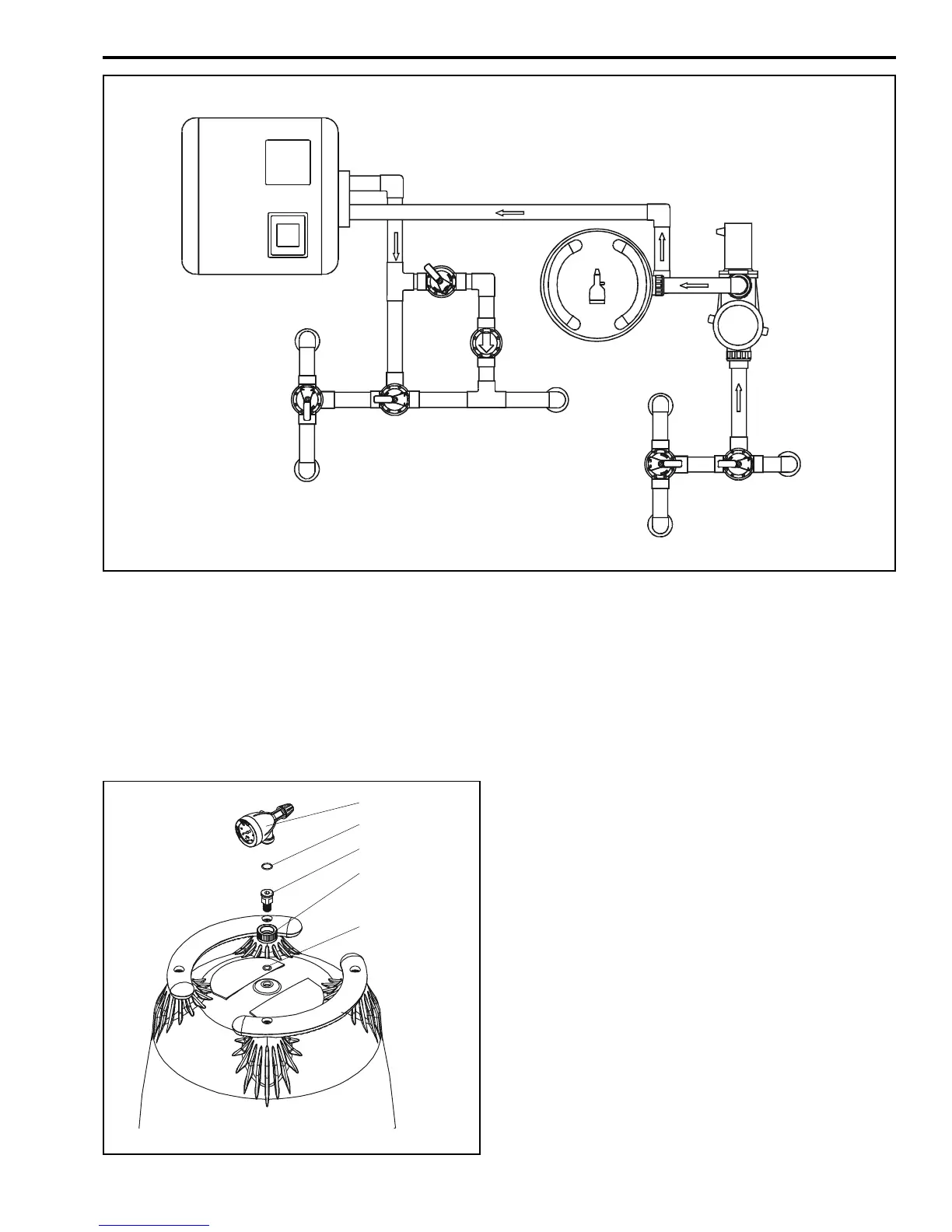

Figure 3. Basic Pool/Spa Combination Plumbing

Laars Heater

Waterfall

Pool Return

Spa Make Up

Spa Return

From Pool Skimmer

From Pool

Drain

Spa Suction

Jandy Pump

Jandy

Check

Valve

Outlet

Port

Inlet

Port

Figure 4. Filter Location

Housing

O-Ring

O-Ring

Tank Adapter

Tank Adapter

to Housing

Coupler

5. To reduce pressure losses, 2" (minimum) piping is

recommended for plumbing the system.

6. For best efficiency use the fewest possible number of

fittings. This will prevent a restriction in the water flow.

7. Make all plumbing connections in accordance with

local plumbing and building codes. Filter connections

are provided with an o-ring seal. To avoid damage to

the o-rings, use only a silicone base lubricant on the

o-rings. Do not use pipe joint compound, glue or

solvent on inlet/outlet coupling nuts.

8. Keep piping tight and free of leaks. Pump suction

line leaks may cause air to be entrapped in filter

tank or loss of prime at the pump. Pump discharge line

leaks may show up as dampness or jets of water.

9. Support the inlet/outlet pipes independently to

prevent any undue strains on the filter MPV.

10. Connect the pipes using the unions supplied with

the MPV. Do not use teflon tape or pipe dope on any

unions. Assemble the unions dry and hand tighten.

11. Be sure that all provisions for waste water disposal

meet local, state or national codes. One hundred

gallons or more of pool water will be discharged during

filter backwashing. Do not discharge water where it

will cause flooding or damage.

Jandy Filter

Loading...

Loading...