SECTION 13

SPECIFICATIONS & GLOSSARY

100

WHEEL LUG TORQUE CHART

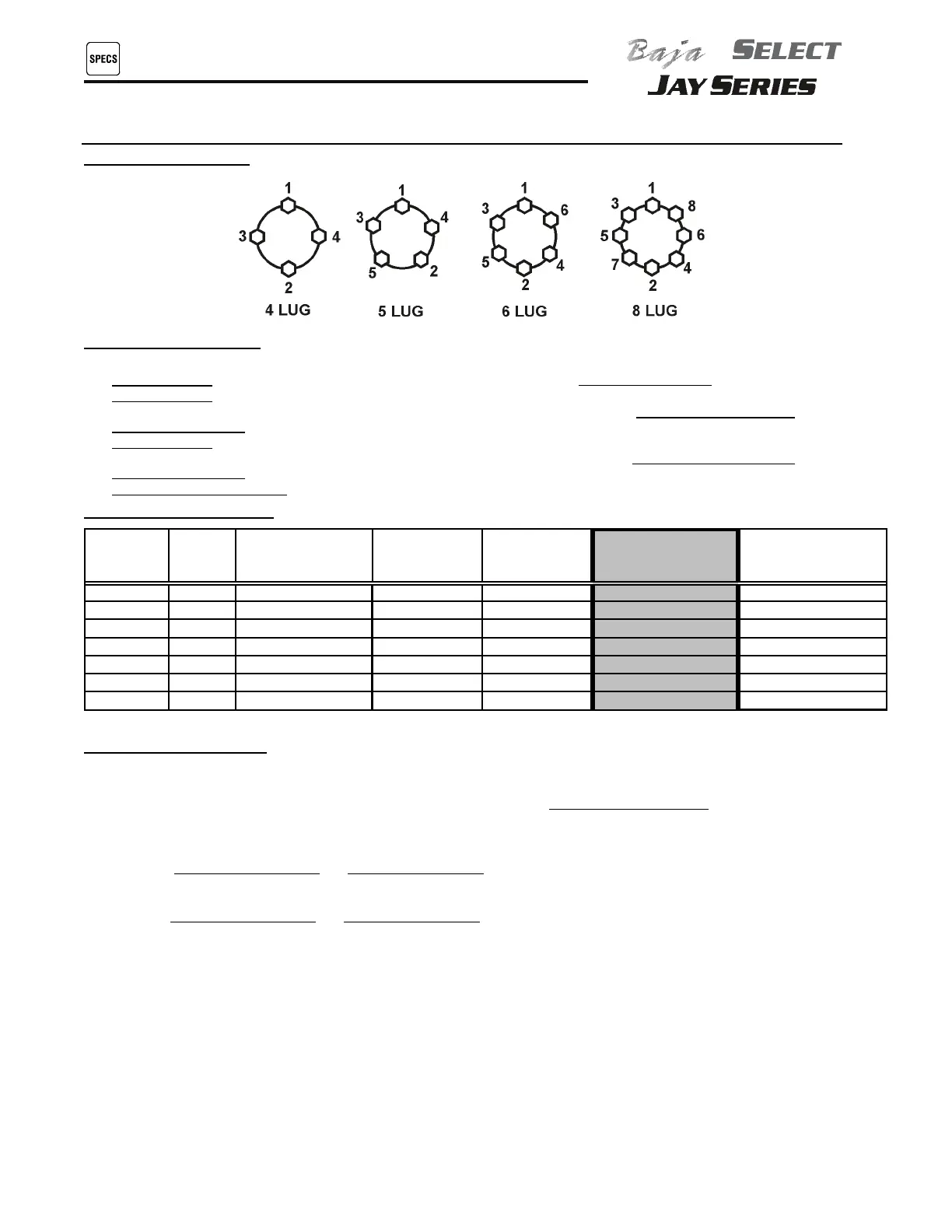

Wheel Lug Nut Diagrams:

Wheel Torque Instructions: * All torque wrenches mentioned below must have settings visible for auditing purposes.

1. Start lug nuts with fingers on studs to avoid cross threading.

2. Stage 1, Torque

: Impact lug nuts in a star pattern* until snug to rim. -- See Wheel Lug Nut Diagram

3. Stage 2, Torque

: Use calibrated torque wrench to torque each lug nut, in a star pattern, to the values indicated.

Wheels must remain stationary during torquing process for control purposes. --

See Wheel Lug Nut Torque Chart and

Wheel Lug Nut Diagram

4. Stage 3, Torque: Use calibrated torque wrench to torque each lug nut, in a star pattern, to the values indicated.

Wheels must remain stationary during torquing process for control purposes. --

See Wheel Lug Nut Torque Chart and

Wheel Lug Nut Diagram

5. Confirmation Torque checks

: Every 10th unit produced must be verified for torque using a calibrated torque wrench

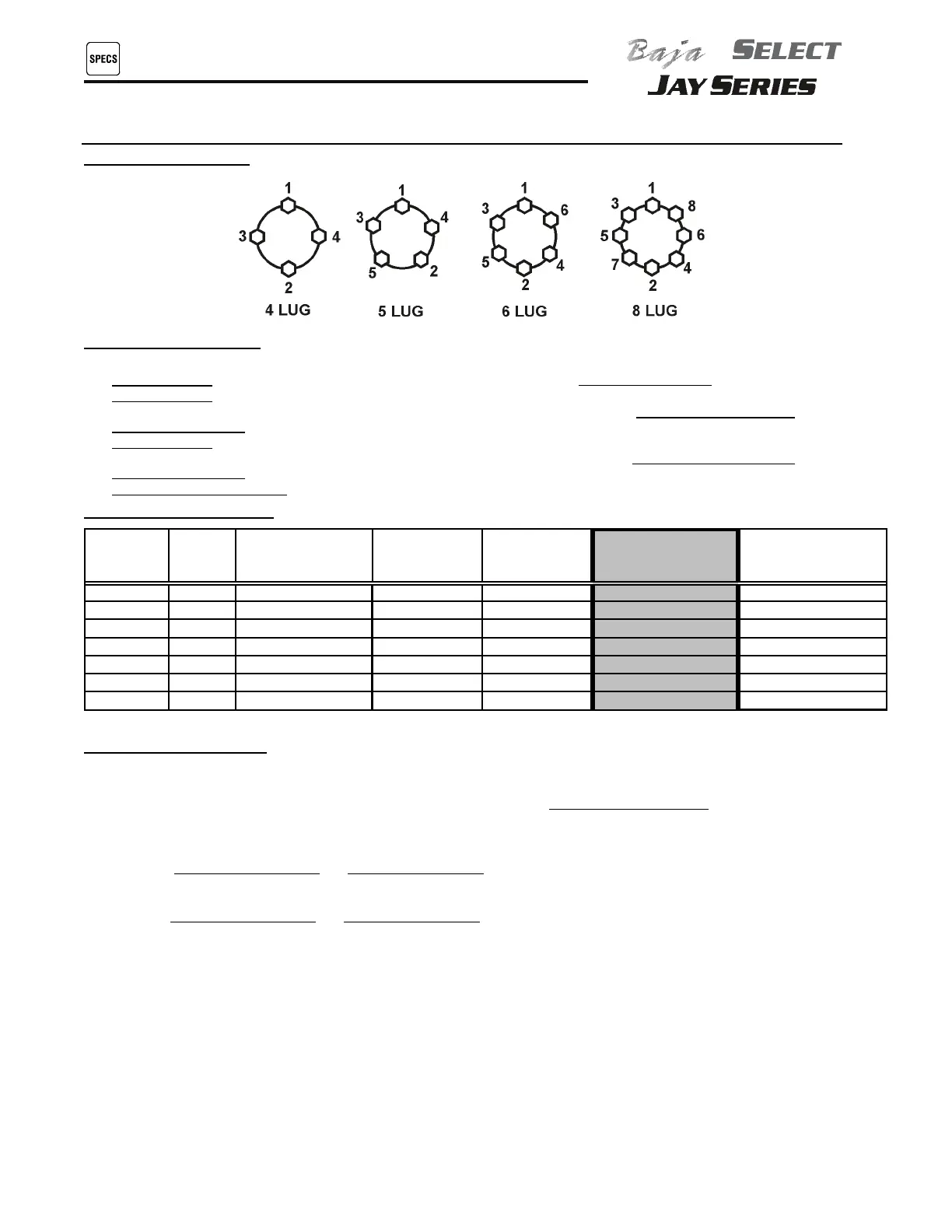

Wheel Lug Nut Torque Chart:

Lug Nut Rim Type

Stage 1 Stage 2

Stage 3

Recommended Final

Torque Range

4-Lug Nuts 12" Steel 20-25 ft/lbs 30-50 ft/lbs 65-75 ft/lbs

5-Lug Nuts 13"

Chrm

/

Steel

20-25 ft/lbs 30-50 ft/lbs 65-75 ft/lbs

5-Lug Nuts 14"

Chrm

/

Steel

/

Alum

20-25 ft/lbs 70-90 ft/lbs 110-120 ft/lbs

5-Lug Nuts 15"

Chrm

/

Steel

/

Alum

20-25 ft/lbs 70-90 ft/lbs 110-120 ft/lbs

6-Lug Nuts 15"

Chrm

/

Steel

/

Alum

20-25 ft/lbs 70-90 ft/lbs 110-120 ft/lbs

6-Lug Nuts 16"

Chrm

/

Steel

20-25 ft/lbs 70-90 ft/lbs 110-120 ft/lbs

8-Lug Nuts 16"

Steel

/

Aluminum

20-25 ft/lbs 70-90 ft/lbs 120-130 ft/lbs

110-130 ft/lbs

90-120 ft/lbs

90-120 ft/lbs

90-120 ft/lbs

Acceptable Torque

Range

50-75 ft/lbs

50-75 ft/lbs

90-120 ft/lbs

Transportation Instructions:

1. Prior to travel and after excessive braking, all wheel lug nuts must be checked for torque.

*This also applies to any service involving wheel or lug removal, during the life of the recreational vehicle.

2. Torque readings must fall within the Acceptable Torque Range. --See Wheel Lug Nut Torque Chart

3. Torque specifications, must be checked by using a torque wrench.

*

Digital or Dial Torque Wrenches are recommended

4. If Torque falls below the Acceptable Torque Range, additional torque is required.

--

See Wheel Torque Instructions and Wheel Lug Nut Diagram for the correct pattern and recommended final torque value.

5. During travel, wheel lug nuts must be checked and re-torqued, as required, after the first, 10 miles, 25 miles, 50

miles, then periodically during travel (16 kilometers, 40 kilometers, 80 kilometers, then periodically during travel).

-- See Wheel Torque Instructions and Wheel Lug Nut Diagram for the correct pattern and recommended final torque value.

6. Failure to follow these instructions may result in wheel loss, an accident, or loss of control, resulting in death or

serious injury.

Loading...

Loading...