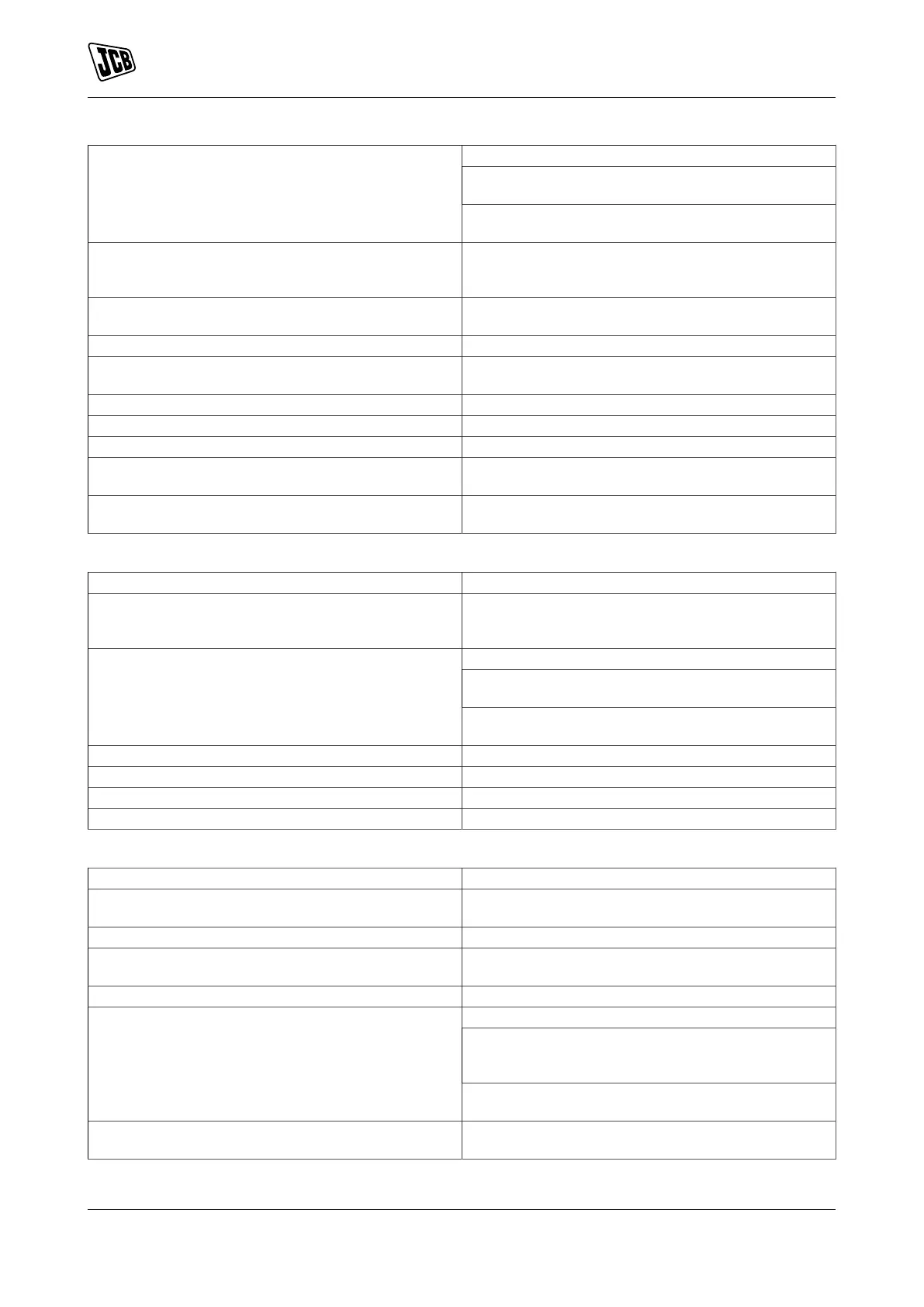

Maintenance

Fault-Finding

123 9831/0650-3 123

Stop the engine.

Replace the fuel filters. Operate the engine with a

temporary supply of the correct grade of clean fuel.

Fuel is contaminated or incorrect grade diesel fuel

used.

Note: Dirty fuel will cause damage to the fuel injec-

tion pump and injectors.

Inlet and exhaust valve clearances set incorrectly. Set the valve clearances to the recommended clear-

ances. Make sure the push rods are not bent or the

rocker levers are not severely worn.

Turbocharger noise. Check turbocharger impeller and turbine wheel for

housing contact.

Inlet and exhaust valve springs broken. Check and fit new valve springs.

Worn crank/connecting rod bearings (knocking under

load).

Check/replace rod and main bearings.

Excessive camshaft bearing wear. Check bearings (engine overhaul required).

Worn or damaged pistons and/or piston rings. Check piston assemblies (engine overhaul required)

One or more fuel injector worn or malfunctioning. Check the electrical connections at the injectors.

Gear train noise. Visually inspect and measure gear backlash. Re-

place gears as required.

Loss of Pilot injection on one or more cylinders. Use service master to disable pilot injections to iden-

tify audibly if they are still present.

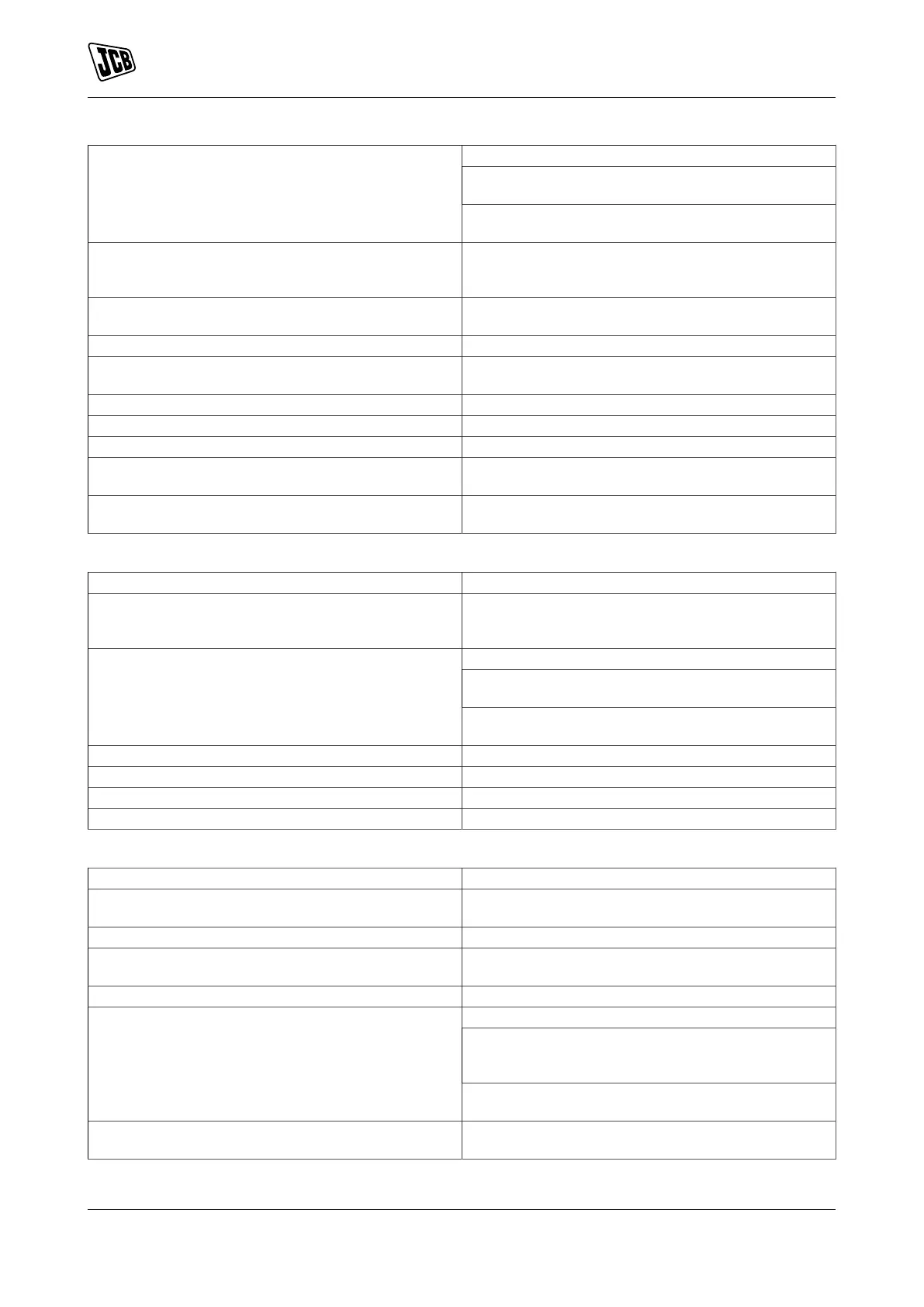

Table 29. Engine - Compression Knocks

Cause Remedy

Fuel is aerated. Check the low pressure fuel system for loose con-

nections and possible air ingress points. Rectify and

bleed the fuel system.

STOP THE ENGINE.

Replace the fuel filters. Operate the engine with a

temporary supply of the correct grade of clean fuel.

Fuel is contaminated or incorrect grade diesel fuel

used.

WARNING: Dirty fuel will cause damage to the fuel

injection pump and injectors.

Electrical sensor fault. Check the electrical connections at the sensors.

Inlet and exhaust valve springs broken. Check and fit new valve springs.

One or more fuel injector worn or malfunctioning. Check the electrical connections at the injectors.

Coolant operating temperature incorrect. Refer to Table 44. and Refer to Table 45.

Table 30. Engine - Reduced Power Output

Cause Remedy

No fuel in supply tank. Check the level in the fuel tank, use sight gauge or

dipstick. Replenish as required.

Oil level incorrect. Check oil level.

Engine overload. Check for added loading from malfunctioning acces-

sories or driven units (alternator).

Throttle position sensor (TPS) system defective. Check the throttle assembly

Stop the engine.

Replace the fuel filters. Operate the engine with a

temporary supply of the correct grade of clean fuel.

Monitor the engine performance.

Fuel is contaminated or incorrect grade diesel fuel

used.

WARNING: Dirty fuel will cause damage to the fuel

injection pump and injectors.

Turbocharger boost control pipe leaking or damaged,

or wastegate diaphragm ruptured

Check boost control pressure. Inspect and tighten fit-

tings, repair pipes, replace wastegate assembly.

Loading...

Loading...