Maintenance

Fault-Finding

125 9831/0650-3 125

One or more fuel injector worn or malfunctioning. Check the electrical connections at the injectors.

Worn or malfunctioning high pressure fuel pump. Do all the necessary fault finding checks before re-

moval of the high pressure fuel pump.

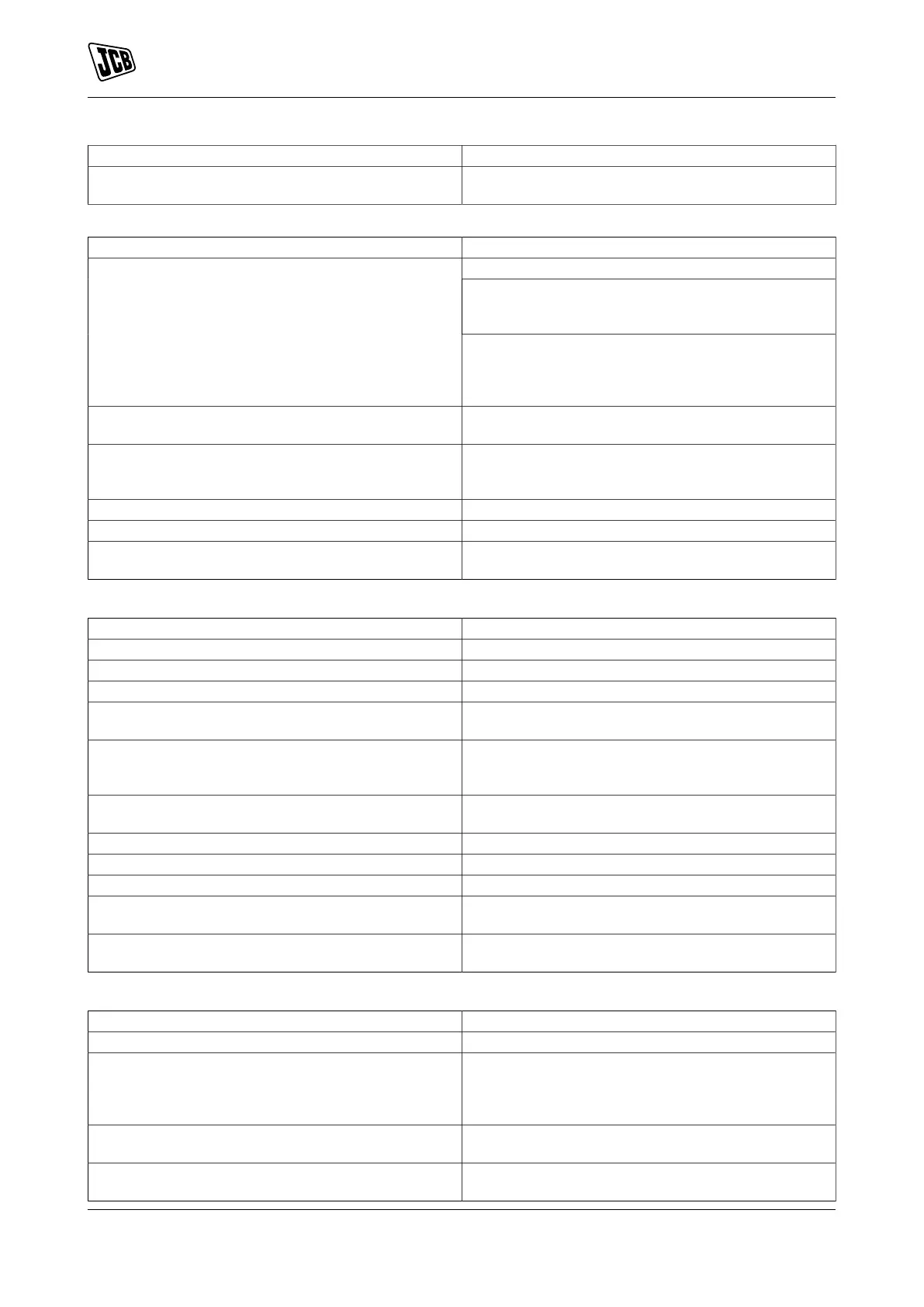

Table 32. Engine - RPM Surges

Cause Remedy

Replace defective high pressure fuel lines.

WARNING: DO NOT repair defective fuel lines. If

there is a fuel leak remove and discard the neces-

sary components and install new ones.

Fuel injection lines leaking.

WARNING: Fine jets of fluid at high pressure can

penetrate the skin. Keep face and hands well clear of

pressurised fluid and wear protective glasses. If fluid

penetrates your skin, get medical help immediately.

Fuel tank cap vent/breather blocked. Inspect and rectify as required - replace cap if neces-

sary.

Fuel is aerated. Check the low pressure fuel system for loose con-

nections and possible air ingress points. Rectify and

bleed the fuel system.

Electrical sensor fault. Check the electrical connections at the sensors.

One or more fuel injector worn or malfunctioning. Check the electrical connections at the injectors.

Worn or malfunctioning high pressure fuel pump. Do all the necessary fault finding checks before re-

moval of the high pressure fuel pump.

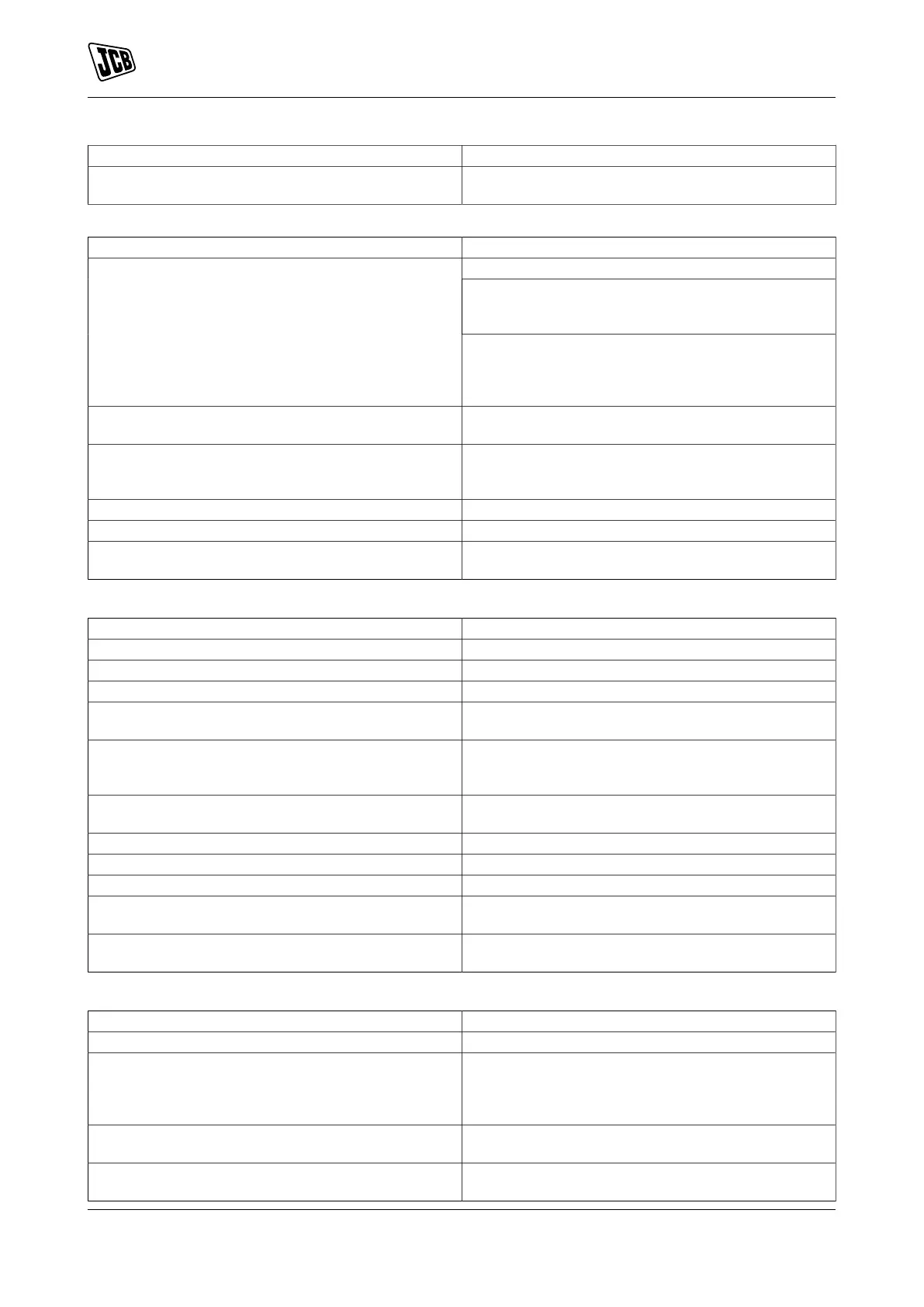

Table 33. Engine - Vibration Excessive

Cause Remedy

Engine not running smoothly/misfiring. Refer to Table 27.

Oil level over-full. Check oil level.

Fan damaged or accessories faulty. Check/replace the vibrating component.

Fan hub faulty. Inspect/replace the fan hub. Refer to workshop man-

ual.

Engine mounts loose or broken. Check/replace engine mounts. Refer to the

machine's service manual for correct installation and

torque figures.

Inlet and exhaust valve clearances set incorrectly. Set the valve clearances to the recommended clear-

ances.

Engine compression low in one or more cylinders. Check the engine compression.

Alternator bearing worn or damaged. Check/replace the alternator.

Flywheel housing misaligned. Check/correct flywheel alignment.

Electrical sensor fault. Check the electrical connections at the ECU (Elec-

tronic Control Unit) and sensors.

Drive line components worn or unbalanced. Check and inspect drive line components such as

propshafts. Refer to workshop manual.

Table 34. Engine - Exhaust Smoke Excessive (Black Smoke)

Cause Remedy

Engine being lugged down. Use appropriate gear for task.

Air intake or exhaust system blocked. Visually check the air intake and exhaust system for

blockage or obstruction - remove as required. Check

the air filter elements for signs of blocking - replace

as required.

Air leak between the turbocharger and the intake

manifold (Turbocharged machines only).

Check/correct leaks in the air crossover tube, hoses,

or manifold cover.

Exhaust leak at the Manifold or Turbocharger (Tur-

bocharged machines only).

Check/correct leaks in the manifold or turbocharger

gaskets. Look for a cracked manifold.

Loading...

Loading...