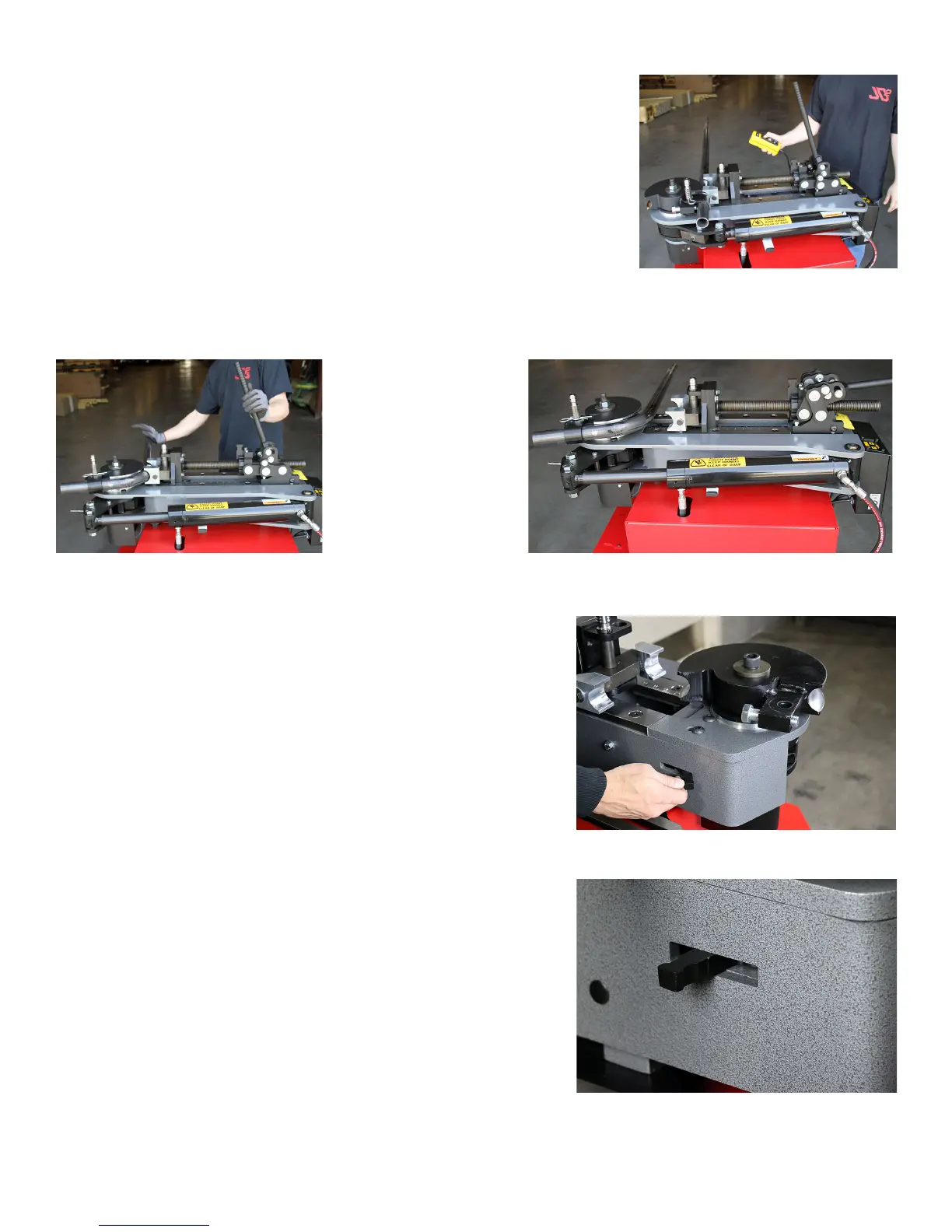

Striking the tube’s end Toggle in the disengaged posyion

How to make a bend and remove the work piece when nished

1) Load the tube to be bent and adjust the toggle as described earlier.

2) Lubricate ONLY the outside of the tube where the pressure die slides.

Do NOT oil the groove. Cooking spray works surprisingly well here.

3) Verify the pressure die’s 1” pin is all the way down and extends below

the lower plate. Verify the u-strap pin extends below the u-strap by a 1/4”

or more and will not hit the button head bolts or frame during bending.

4) Stand well clear of the toggle lever’s ENTIRE range of travel. Injury may

result in the extremely unlikely event the lever snaps back under load.

5) Press the ram advance button on the pendant to start bending.

6) Upon completion, retract the ram a few seconds to relieve the bending

pressure. Most of the time the tube will come loose by itself. However,

you may hit the rear of the tube as shown below to help dislodge it.

7) Press the safety bar down and retract the toggle lever. You can now remove the tube.

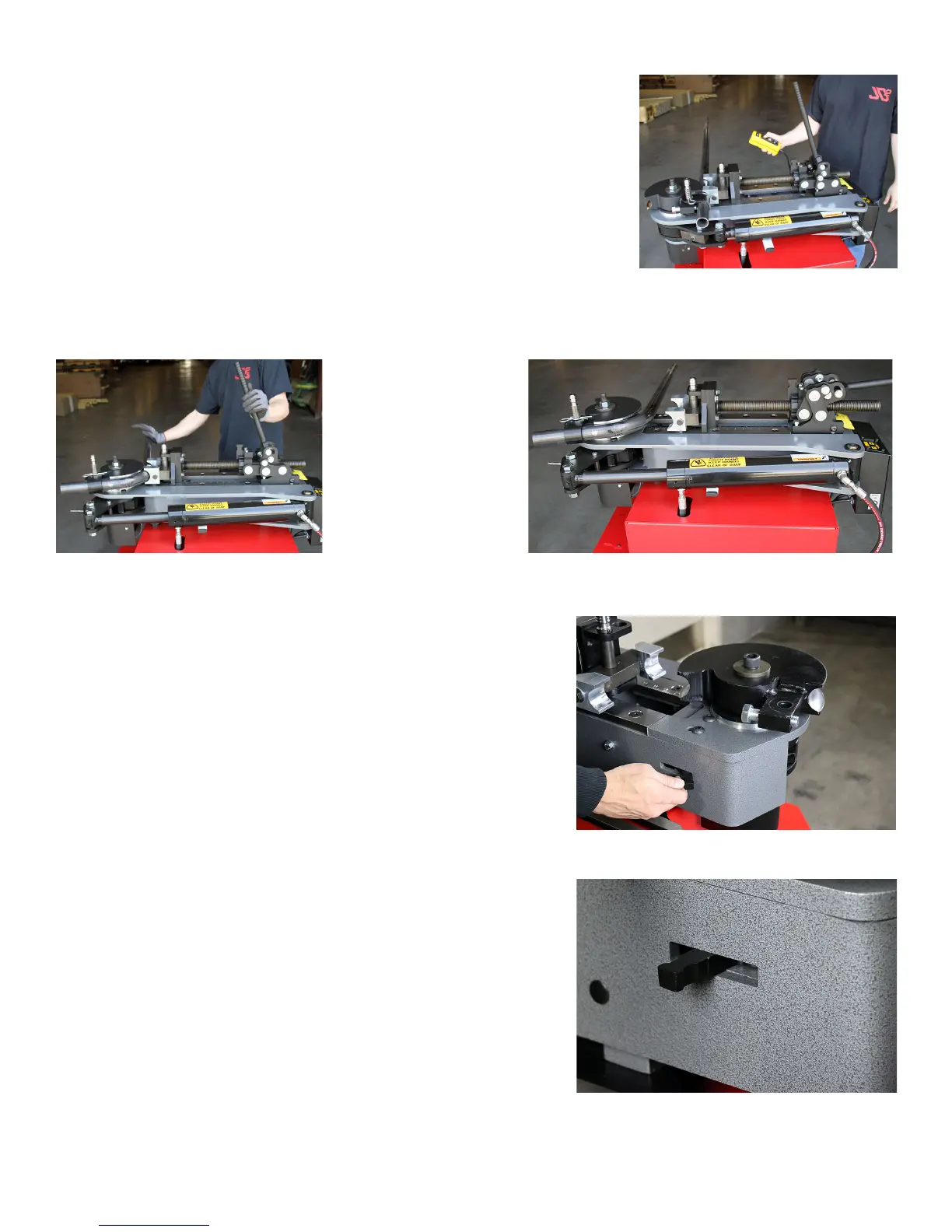

Spindle lock operation

When activated, the spindle lock will engage at 22.5

o

intervals

to prevent the forming die from rotating counter-clockwise. This

is necessary if for any reason the bend process must be stopped

and the cylinder is retracted such as making a 180

o

bend. If the

spindle is allowed to rotate backwards the pressure on the tube

relaxes allowing the tube to lift slightly in the die groove. This can

cause problems when the bend is continued. It is the main cause

of wrinkling thin wall tubing (.065” or less). The tube may also slide

backwards in the die making it very difcult to obtain accurate

bends.

The spindle lock is not needed for bends up to 90

o

because a

single stroke of the ram advances the spindle approximately 115

o

.

To disengage it, push the lever forwards as shown to the right. For

bends greater than 90

o

use the procedure below.

1) Engage the spindle lock by moving the lever to the rear position

as shown to the right.

2) Press the pendant button and start bending. Every 22.5

o

you will

hear the spindle lock click into the locked position. You can also

see the lever moving back and forth as the bend progresses.

At approximately 90

o

of bend you will hear the spindle lock

engage again. Immediately stop bending. Try to stop the

bender as close as possible after the lock has engaged.

3) Retract the ram until the drive pawl engages another tooth. If

you retract it all the way to its start position, a full 180

o

bend

can be made with only two shots of the ram.

4) When the bend is complete, move the latch to the forward position to disengage the spindle lock.

5) You can now remove the tube is described in an earlier section.

e spindle lock in the disengaged position.

e spindle lock in the engaged position.

Pressing the advance button

Page 12

Loading...

Loading...