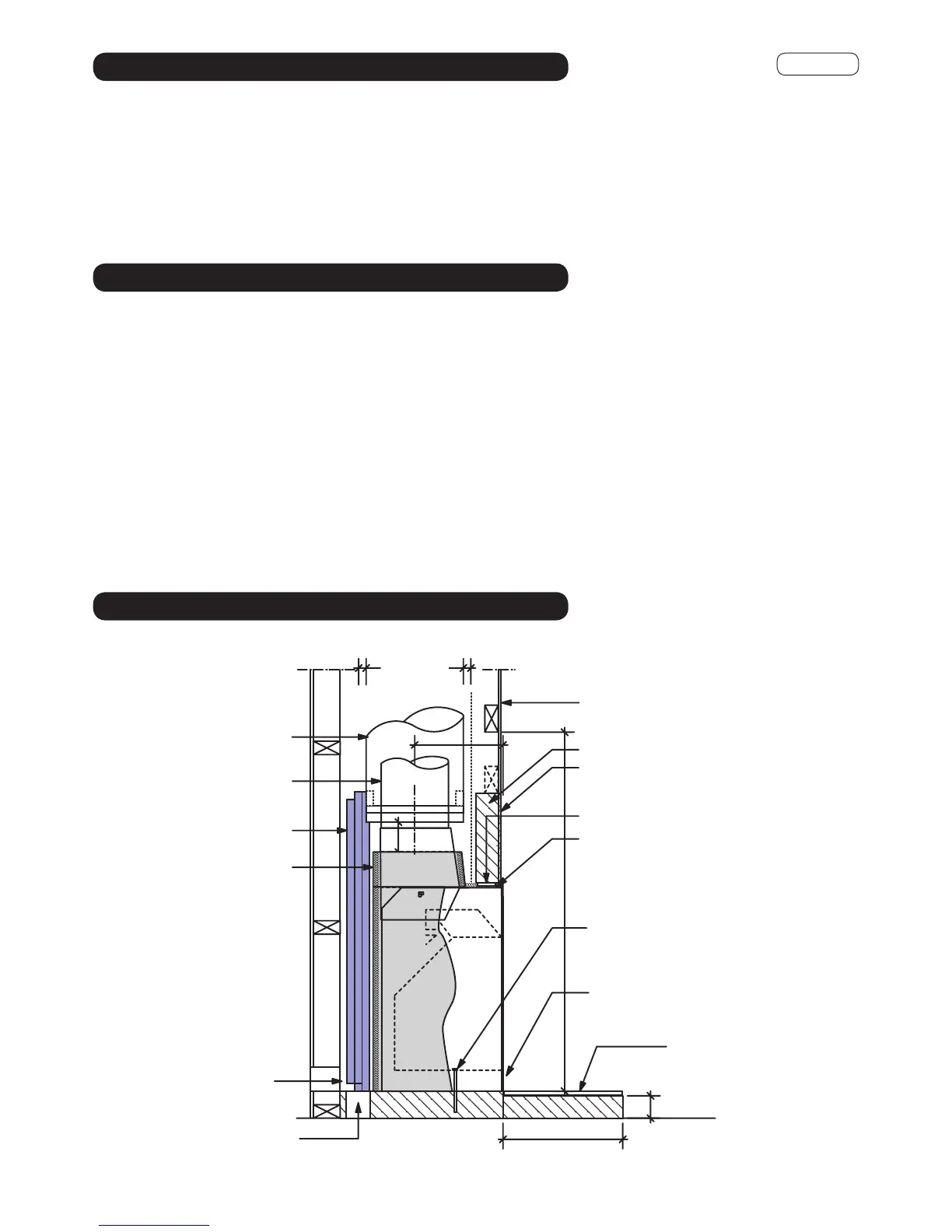

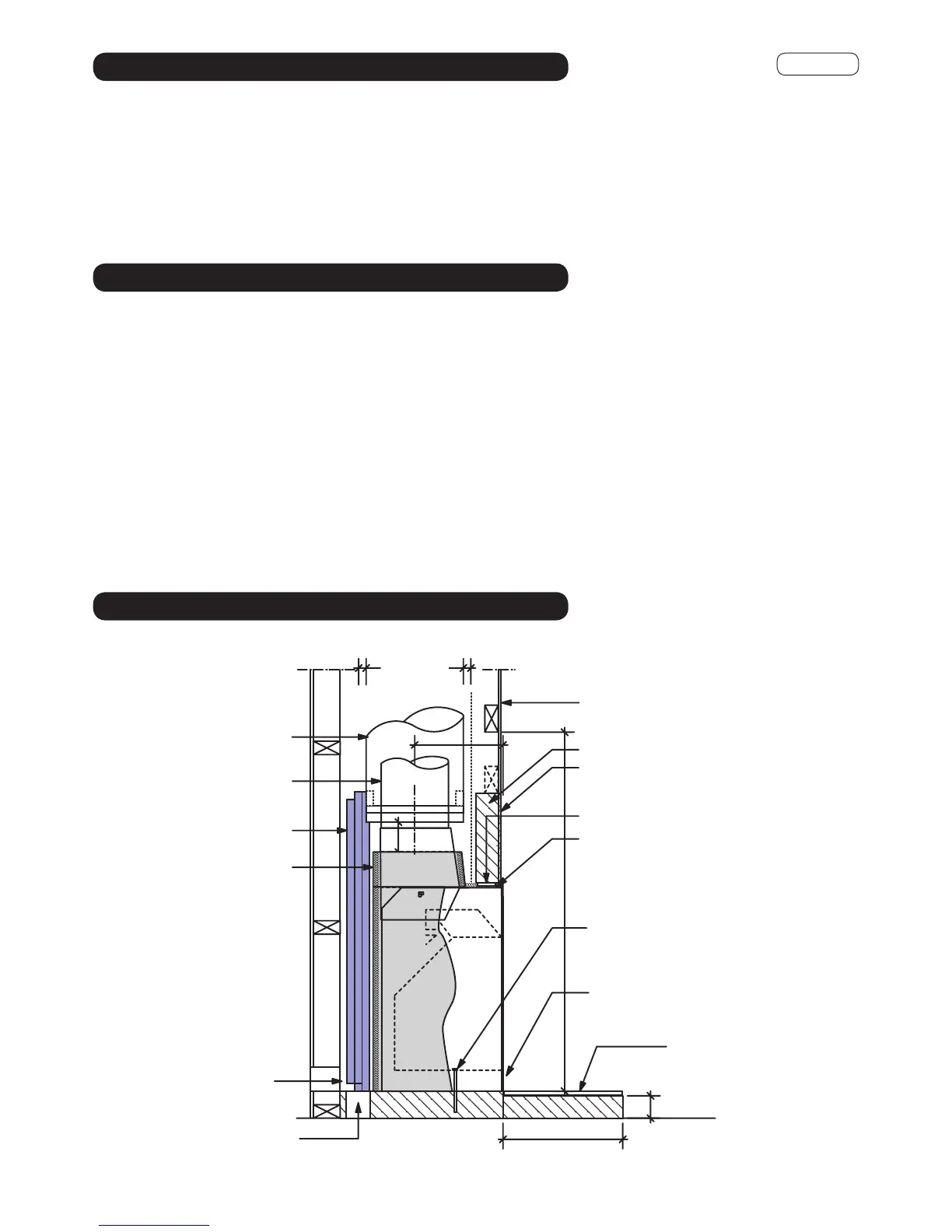

1. All dimensions shown for the framing trim out and metal heat shields, are based on a maximum frontal clearance

between the timber framing and the rear of the firebox fascia, being not more than 15mm.

2. Locate floor protector in trim out cavity. If on a concrete floor, suggest a mortar screed to the underside of the floor

protector. If on a wooden floor, screw or dynabolt in place.

3. Locate stud openings on both sides.

4. Position and ensure a strip of glass rock wool insulation is between the inner hebel leg face and the firebox. Nail

through stud into hebel leg to secure in place.

5. Locate and position firebox, fit and seal gather in cavity (refer to Cross Section). Earthquake restraints may be

positioned by drilling through firebox into the floor protector, in a position midway beneath the log-pan. Two 12mm

dynabolts or similar will suffice. Do not over tighten and deform firebox.

6. Attach rock wool to the sides & back of the firebox and gather. DO NOT BLOCK OFF the air entry between the inner

flue pipe and flue pipe casing or the air circulation between the vent holes in the cavity.

7. Once the flue system is installed, place a minimum 300mm hebel block over the top of the firebox (see Fig. 8).

Ensure the hebel block does not rest on top of the firebox. A Lintel Bar may be required.

100

Y

min

75

25

25

B

Refer to the minimum framing dimensions as per table 2. Allow a temporary lintel height (see table 2 ‘B’) from the

finished floor protector level until the firebox and flue system is installed. Install front nogs on edge to increase chimney

chase dimension.

Ensure suitable air vents (2 x 80mm diameter or equivalent) in place to vent firebox space - these maybe located in the

floor or in the side wall space. Ensure vents must be bird and vermin proofed.

Note: Wood Installations can be converted to Gas at a later date. or have a gas ignition system fitted. Consider running

a gas supply to firebox cavity at the time of construction.

Fig.8

Flue Pipe Casing

S/S Flue Pipe

Heat Shield

Rock Wool

Insulation

min 25mm from flue pipe casing to combustible material

Note: All external air vents

& ceiling penetrations must

be bird & rodent proofed

with permanently fixed

screens

Gib Board

Hebel Block

Non combustible material

(Promina, Eterpan LD, Supalux)

Lintel Bar

Rock Wool insulation

(see Table 2)

Secure the firebox with 2 x

12mm Dynabolts in a midway

position beneath the log pan

Maintain the air intake

unobstructed

Rebate to suit tiles or other non com-

bustible material on Floor Protector

Floor Protector

see Table 4

It is important to ensure the Jetmaster firebox is seated at the

required finished Floor Protector level

min 2 x 80mm dia

or equal square or

rectangle shaped air

vents to be wall or

floor mounted

Drawing Not To Scale

CROSS SECTION

FIREBOX INSTALLATION

CAVITY / FRAMING PREPARATION

5.TW.1D

Loading...

Loading...