Jetson

www.JetsonHVAC.com

95

Appendix B

Piping System Flushing Procedure

Prior to connecting the chiller to the condenser and

chilled water loop, the piping loops shall be

flushed with a detergent and hot water (110-

130°F) mixture to remove previously accumulated

dirt and other organics. In old piping systems with

heavy encrustation of inorganic materials consult

a water treatment specialist for proper passivation

and/or removal of these contaminants.

During the flushing, 30 mesh (max.) Y-strainers

(or acceptable equivalent) shall be in place in the

system piping and examined periodically as

necessary to remove collected residue. The use of

on-board chiller strainers shall not be acceptable.

The flushing process shall take no less than 6

hours or until the strainers when examined after

each flushing are clean. Old systems with heavy

encrustation shall be flushed for a minimum of 24

hours and may take as long as 48 hours before the

filters run clean. Detergent and acid

concentrations shall be used in strict accordance

with the respective chemical manufacturer's

instructions. After flushing with the detergent

and/or dilute acid concentrations the system loop

shall be purged with clean water for at least one

(1) hour to ensure that all residual cleaning

chemicals have been flushed out.

Prior to supplying water to the chiller, the Water

Treatment Specification shall be consulted for

requirements regarding the water quality during

chiller operation. The appropriate chiller

manufacturer's service literature shall be available

to the operator and/or service contractor and

consulted for guidelines concerning preventative

maintenance and off-season shutdown procedures.

Water Treatment Requirements

Supply water for both the chilled water and

condenser water circuits shall be analyzed and

treated by a professional water treatment specialist

who is familiar with the operating conditions and

materials of construction specified for the chiller's

heat exchangers, headers and associated piping.

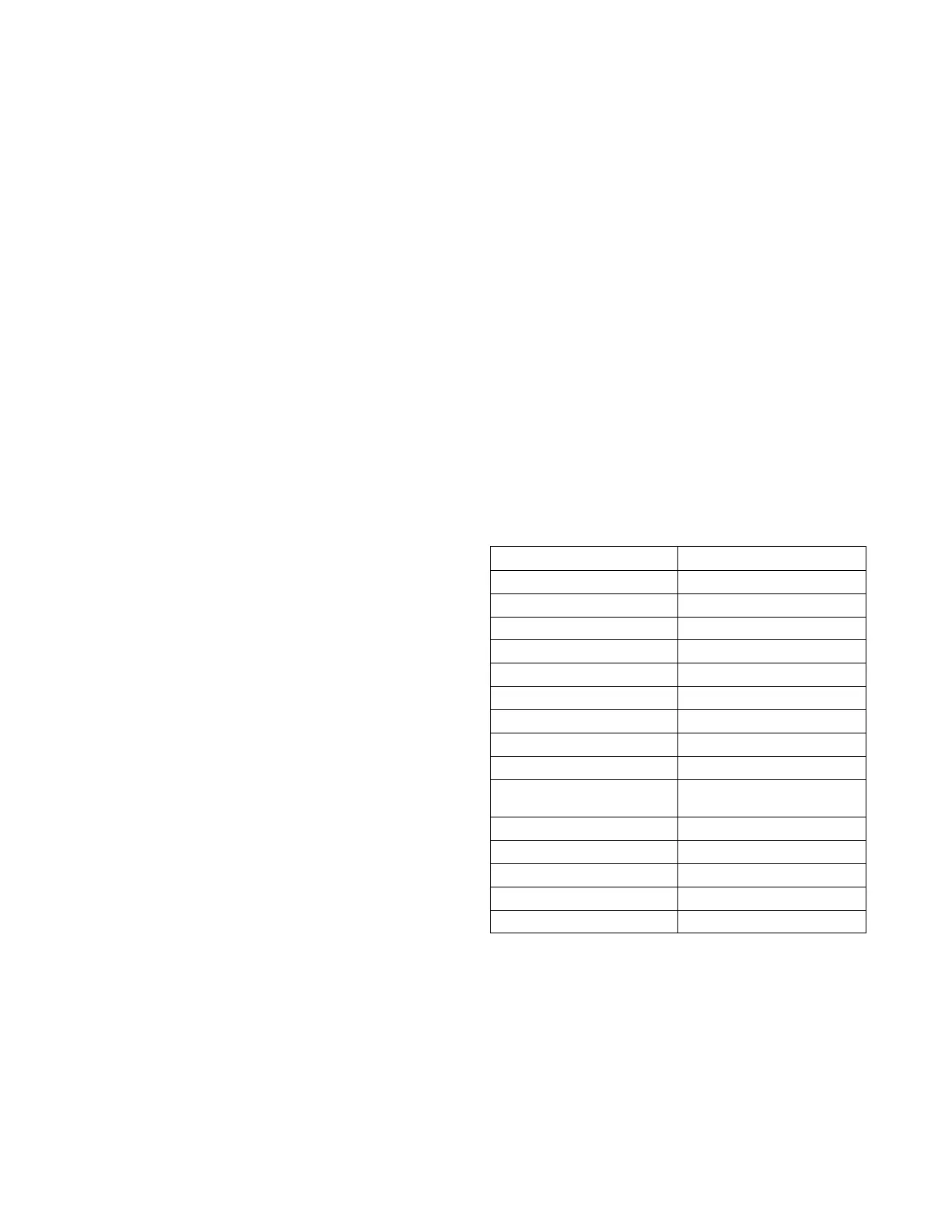

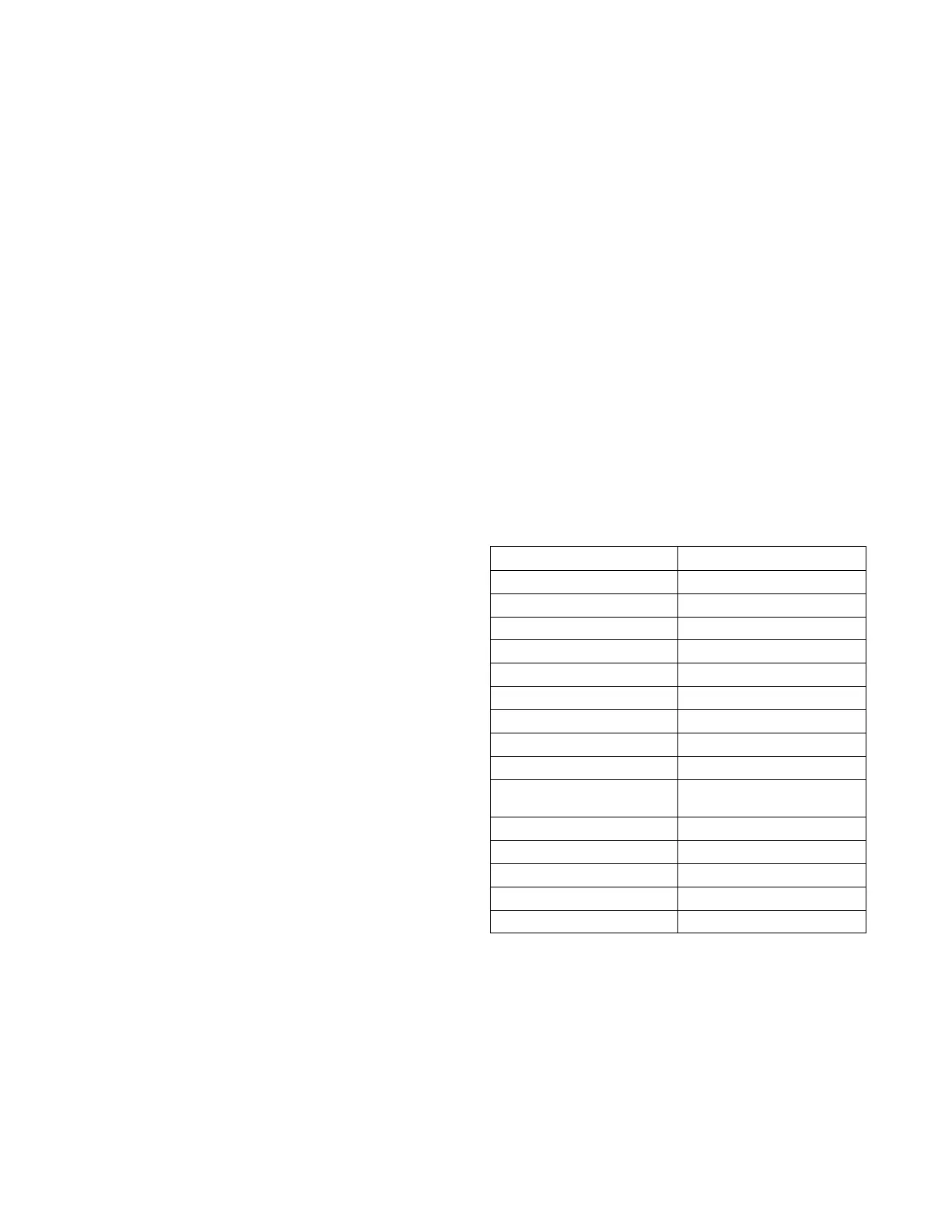

Cycles of concentration shall be controlled such

that recirculated water quality for compact chillers

using 316 stainless steel brazed plate heat

exchangers and carbon steel headers is maintained

within the following parameters.

Figure 37. Water property limits

Loading...

Loading...