4610, 4615, 4620P, 5610, 5610D, 5610L, 5610P, 5610Q, 5610VL,

5610VQ, 5611, 5611L, 5611Q, 5615, 5615L, 5615Q, 5620, 5620D, 5620P,

5620VP, 5620V, 5625, 5625P, EZ-1, FFET, SB1, SB1A, SB2, SB2A, SBW

STANDARD CARTRIDGE SEALS

Installation, Operation & Maintenance Instructions

5

TYPE

Before installing the mechanical seal read the instructions carefully. Keep

for future use. Seal installation must only be carried out by a suitably

qualified person.

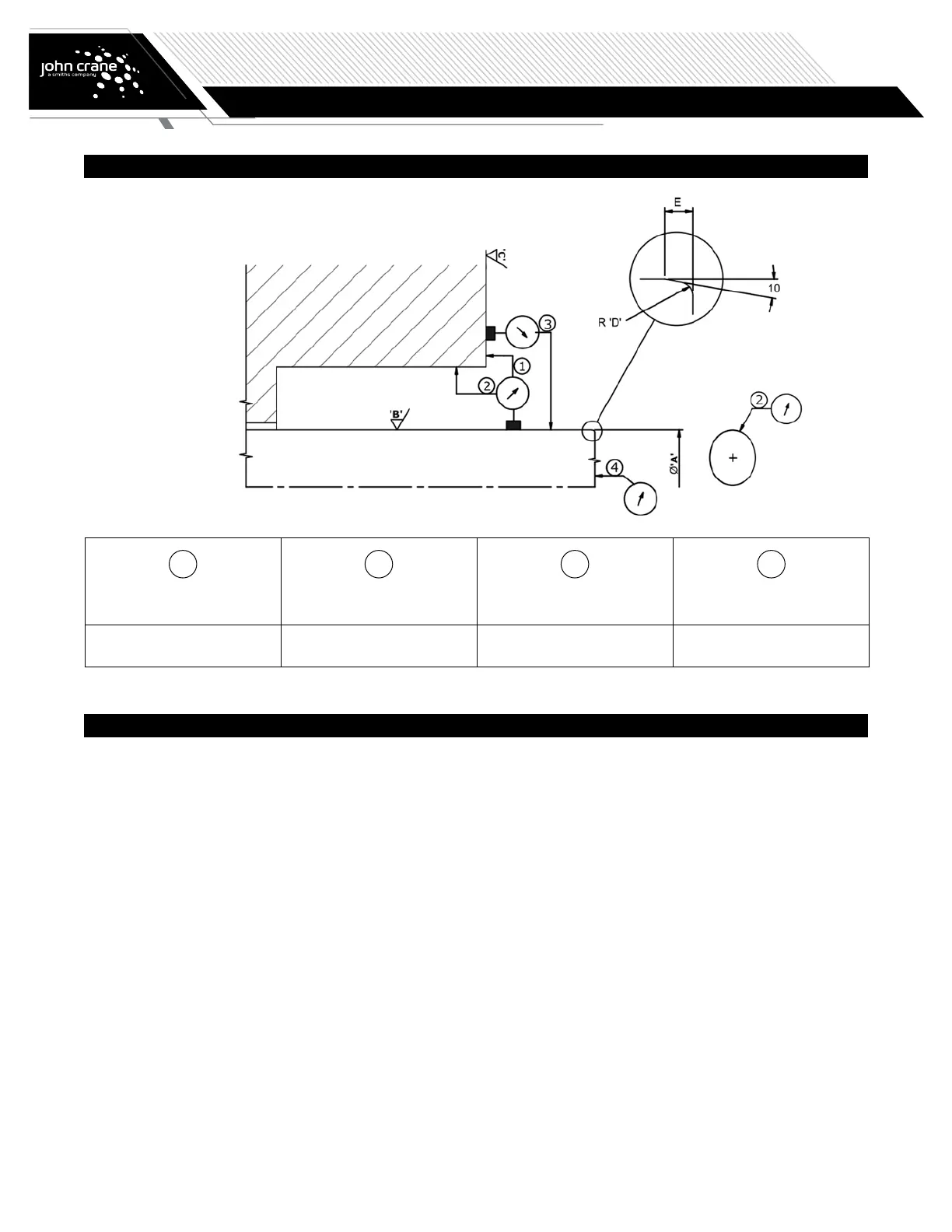

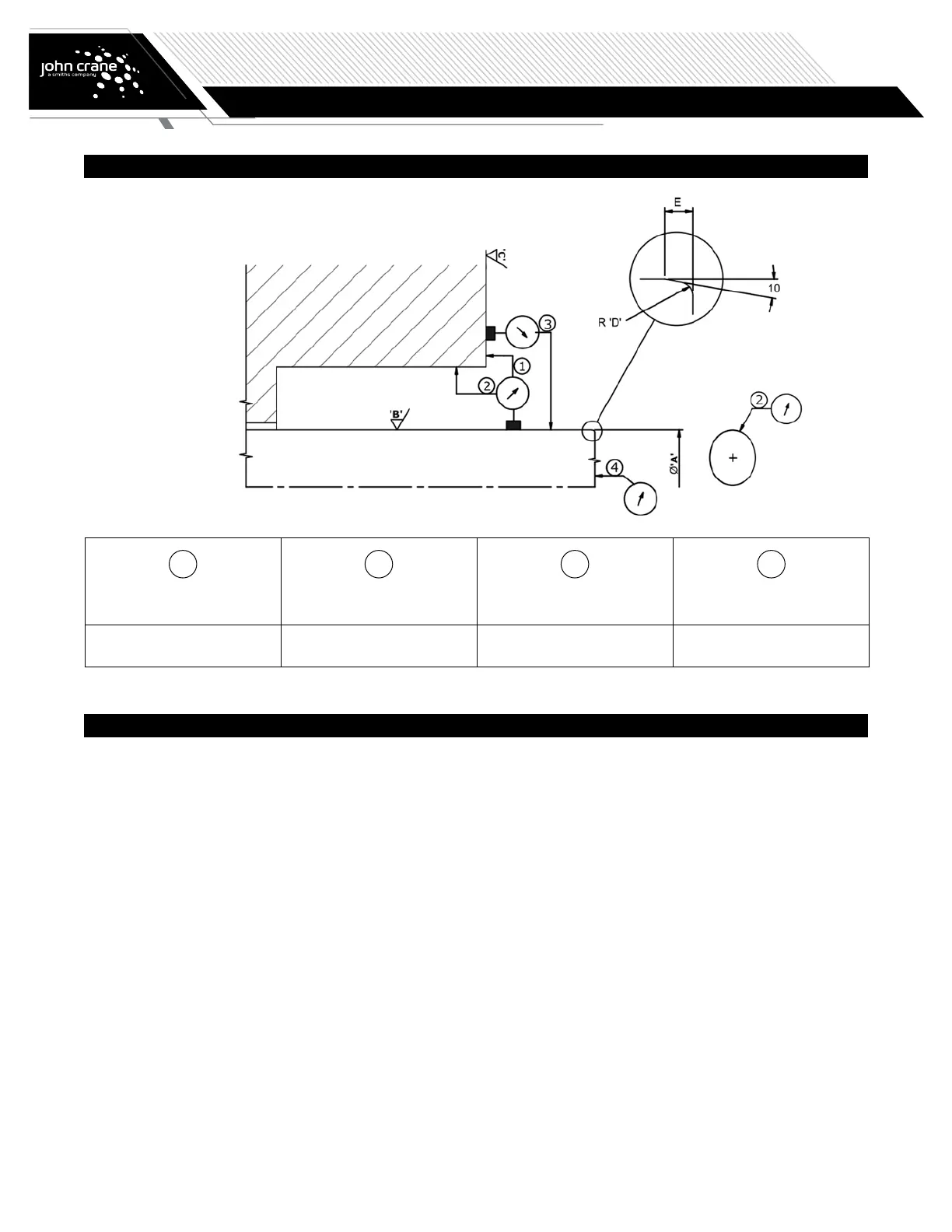

1. Check that the machine is clean and meets the fitting tolerances shown

in the figure above. (Misalignment can lead to excessive friction on the

PTFE centering device on 4610, 4620, EZ-1 and 4615 range).

2. Unpack cartridge, inspect for damage, wipe clean.

3. Lubricate the machine shaft or sleeve with a recommended lubricant.

See Recommended Properties of Barrier Liquids for Dual Seals, page 9.

4. Slide the cartridge on to the machine shaft or sleeve and rotate until the

barrier inlet port ports are in a suitable position for flush piping.

5. Ensure that gland plate sealing ring is in position then slide the cartridge

against the seal chamber.

6. Fit the gland plate fasteners and evenly tighten to the torque

recommended by the machine manufacturer.

7. Ensure the machine shaft is locked axially in its final correct position and

evenly tighten the cartridge drive collar socket set screws. See Table 1 or

Table 2 depending on cartridge type for torque values.

8. Remove any setting clips or spacers and store for future use in cartridge

removal. For EZ-1, 4610, 4615 and most 4620P seals there are no setting

clips to remove.

9. Turn the machine shaft by hand if possible to ensure free rotation with no

shaft binding.

10. Complete the required piping to the seal. See pages 6 and 7. Take care

not to use excessive thread sealant when making circulation pipe work

connections. Unused tapped connections must be safely plugged before

seal operation.

11. Ensure machine seal chamber and seal are safely vented before starting

the machine. This should be achieved through self-venting pipework.

When manual vents are necessary they must be installed and used

safely.

12. For liquid lubricated dual seals ensure that the seal lubrication system

is correctly filled with suitable liquid. See Recommended Properties of

Barrier Liquids for Dual Seals on page 9 for guidance on liquid selection.

13. For a dual pressurized arrangement ensure that the seal is pressurized to

a minimum of 1bar above the maximum machine seal chamber pressure

before the machine is pressurized. The seal pressure must be within the

seal and seal lubrication system operating pressure.

Once fitted, no adjustment is possible during the life of the mechanical

seal. When the mechanical seal requires replacement, John Crane can

supply a new or reconditioned seal to the original specification.

A – Seal size

B – 0.2-0.5 μm Ra

8-20 μinch Ra

C – 1.6-3.2 μm Ra

63-125 μinch Ra

D – 1.0 mm/0.040 inch

E – 1.5 mm/0.060 inch

1

Squareness of shaft

to seal chamber face

2

Concentricity seal

chamber bore to shaft

3

Shaft runout

4

Shaft end play

0.001 mm/mm diameter

0.001 inch/inch diameter

<0.13 mm FIM

<0.005 inch/FIM

<0.05 mm FM

<0.002 inch/FIM

<0.13 mm FIM

<0.005 inch/FIM

Installation Instructions

Checking the Machine

Loading...

Loading...