6

FOR SERVICE ASSISTANCE, CALL 800-433-0708 OR VISIT JOHNDOW.COM

HOW TO COMPLY WITH §178.604 AND §173.28

PRODUCTION TESTING AND REUSE

The fuel station user or third party should complete the inspection and leak-proof test prior to reuse.

Inspection for evidence of a reduction in structural integrity. This is determined by the person

doing the inspection. It is suggested the person inspect for ruptures, creases, cracks, corrosion, bent

llerneck,damagedcap,and/orbrokencapvalve.Fillcapsandcomponentsmaybereplaced.Do

not recondition or use if the tank has a reduction in structural integrity after inspection.

Leakproofness testing. Perform on an empty JDI-FST15 tank only. Apply a 3.0 psi air pressure and

using a test method per Appendix to Part 178 – Alternate Leakproofness Test Methods. Acceptable

methodsinclude:

1) Pressuredifferentialtestbyholdingforsufcienttimetodetermineifthereisachangein

pressure.

2) Solution over seams test by coating all seams and welds with a soapy water solution and

holdingforasufcientperiodoftimetodetermineifairisleaking.

Apackagepassestheleakprooftestifthereisnoleakageofairaftersufcienttimeafterestablishing

3.0psiinsidethetank.Typically,30-60secondsisasufcientamountoftime.

Marking to indicate successfully-passed inspection and leakproofness test. Mark the packaging

with the letter “L”, the name and address or symbol of the person conducting the test, and the last

two digits of the year the test was conducted. Symbols, if used, must be registered with the Associate

Administrator.

Equipment. A Leakproofness Test Kit, JDI-FST15-TK2, for model JDI-FST15 is available from

JohnDow Industries. The kit includes the necessary test equipment, instructions, and blank marking

labelstowriteonandafxtothetank.

Model JDI-FST15 is a DOT approved packaging for the transport of UN 1203, Gasoline, Packing

Group II. The marking plate on the product designates the packaging was tested including leakproof-

nesstestingper49CFR§178.604duringproductionbeforebeingrstusedintransportation.

However, in order to assure the integrity and performance of the packaging, 49 CFR §178.604 also

requires production testing prior to reuse per 49 CFR §173.28. §173.38 requires inspection for a re-

duction in integrity, leakproofness testing, and marking.

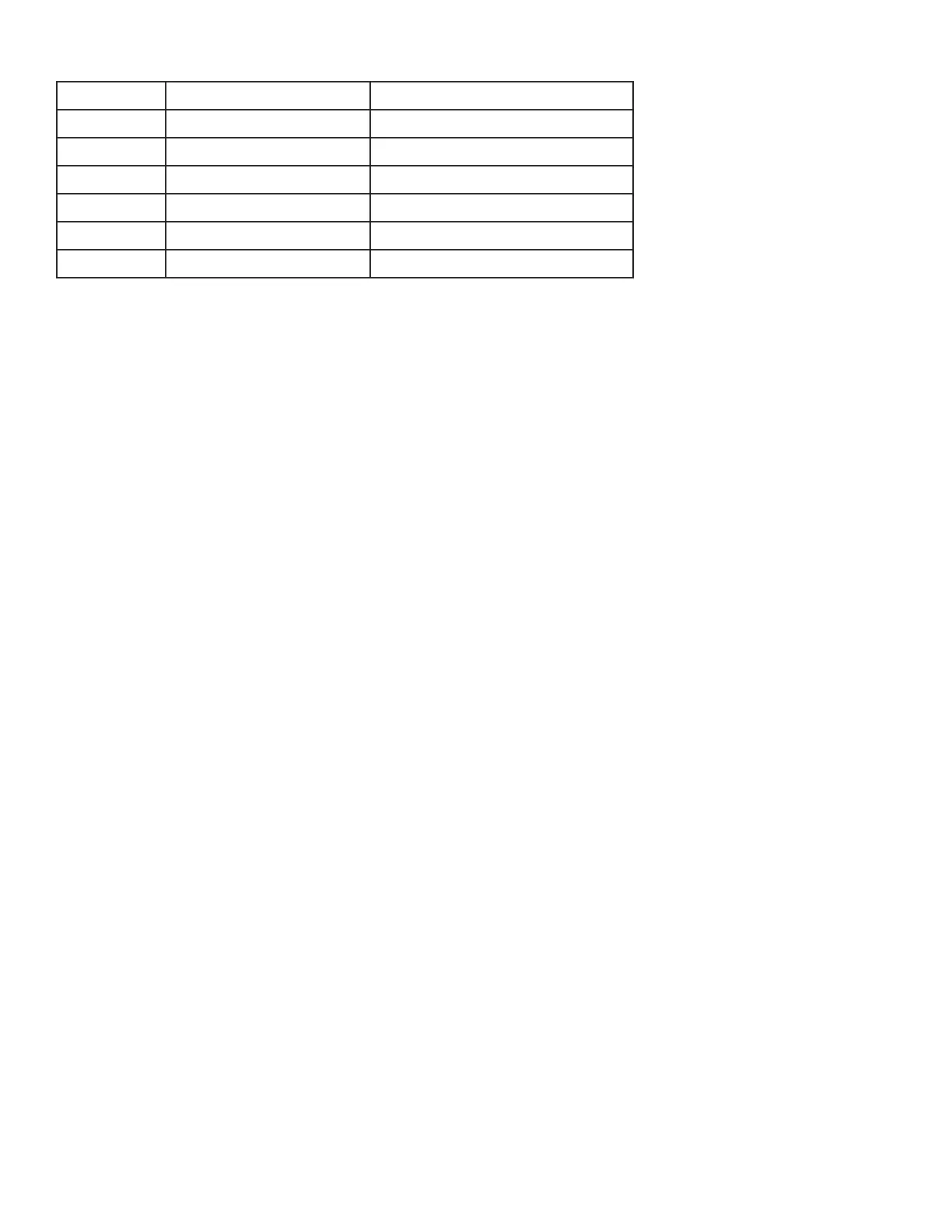

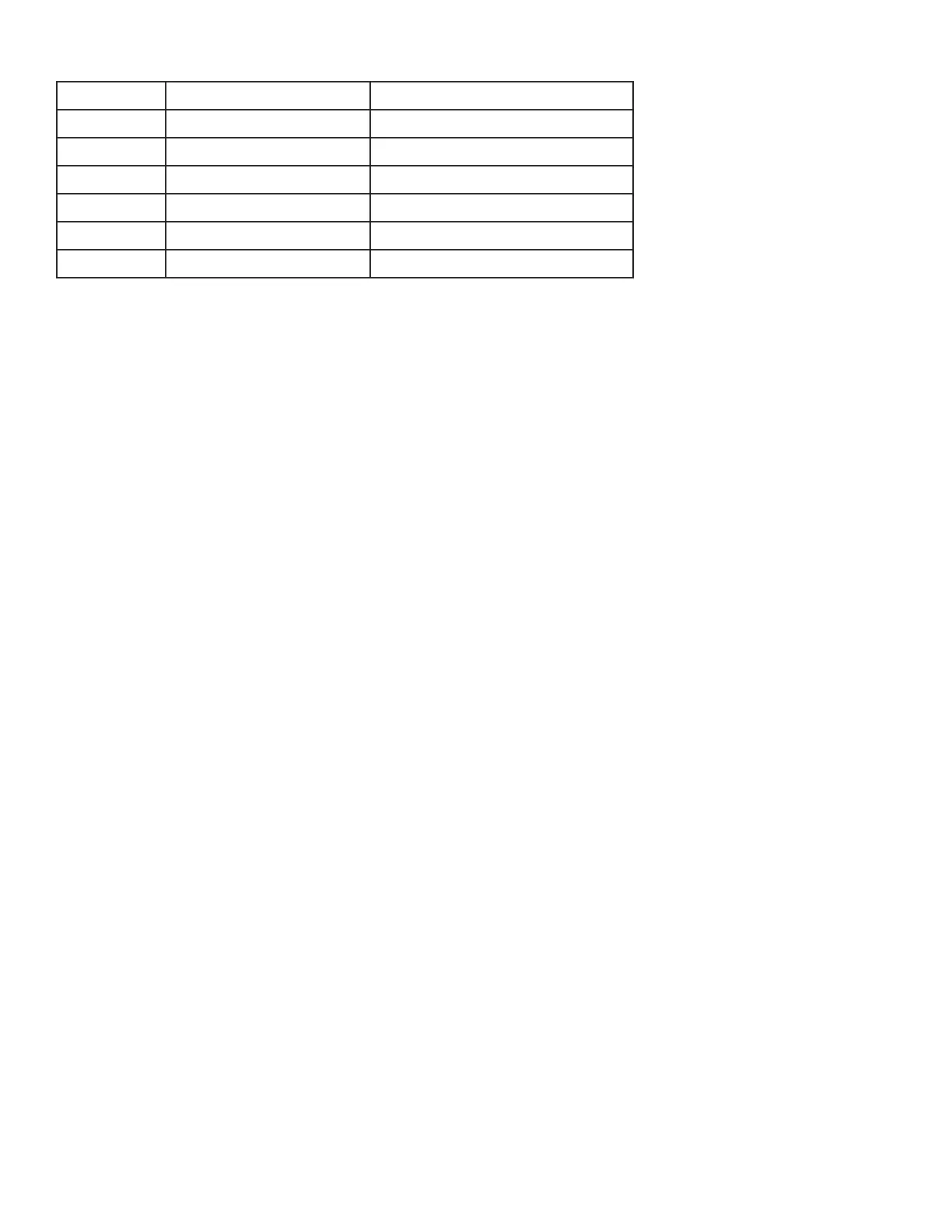

REPLACEMENT PARTS

Item No. Part No. Description

1 FST15-BV 1/2” F x F Ball Valve

2 201594 2-1/4” Fill Cap w/Rubber Gasket

3 FST15-EB 1/2” NPT M x M 90° Elbow

4 30GC-49-OM Ground Wire Assembly

5 FST15-HOSE 10' Hose, 1/2” NPT, 3/4” NPT

6 FST15-NOZZLE Dispensing Nozzle

Loading...

Loading...