F61 Series Standard Flow Switches Installation Instructions 5

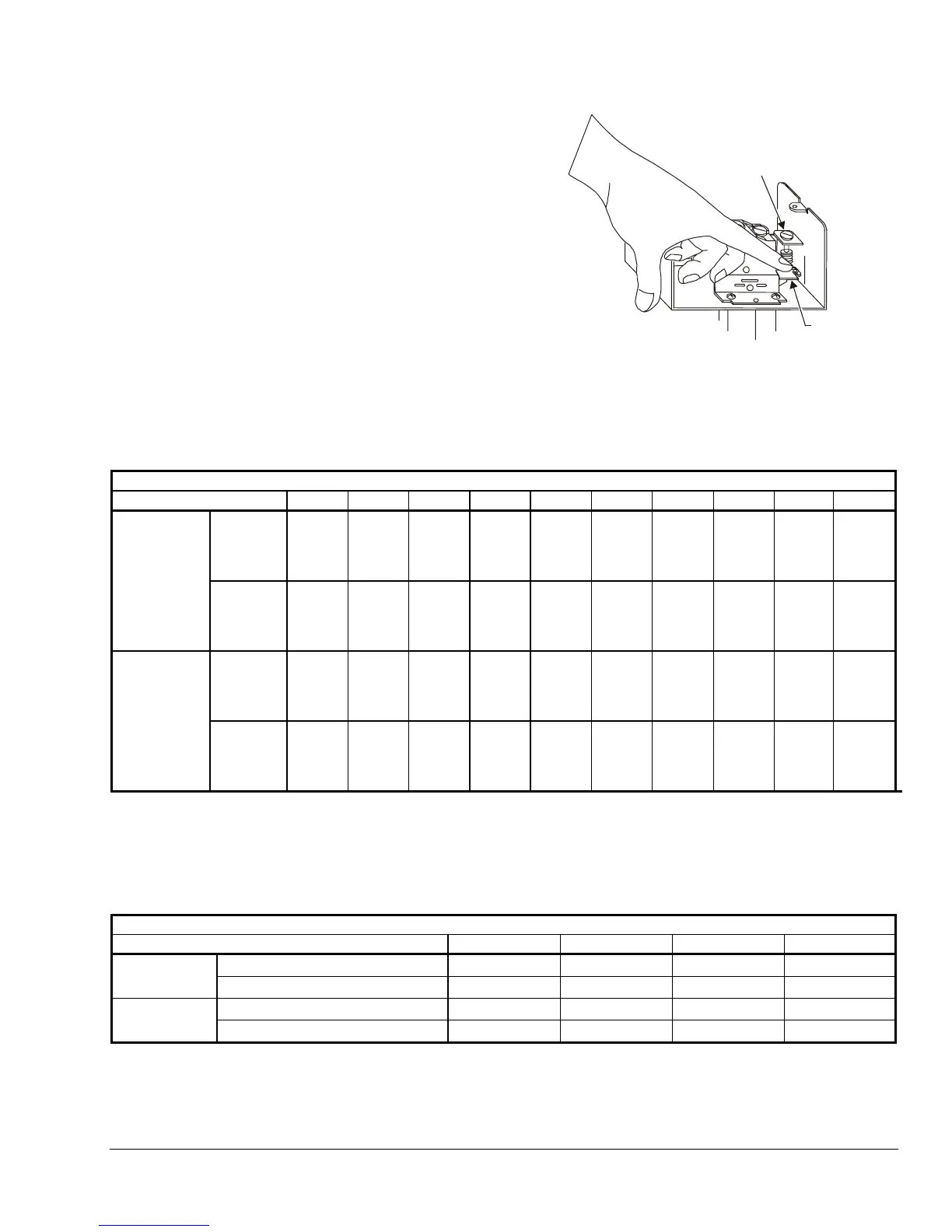

To verify that the flow rate is set above the factory

minimum (see Figure 9):

1. depress the main lever numerous times. If the

lever fails to click upon return at any time, the flow

rate is set below the factory-set minimum.

2. raise the flow rate to approximately the factory

minimum by turning the adjusting screw clockwise

until the lever clicks upon return every time.

Adjusting

Screw

Main

Lever

Figure 9: Minimum Adjustment

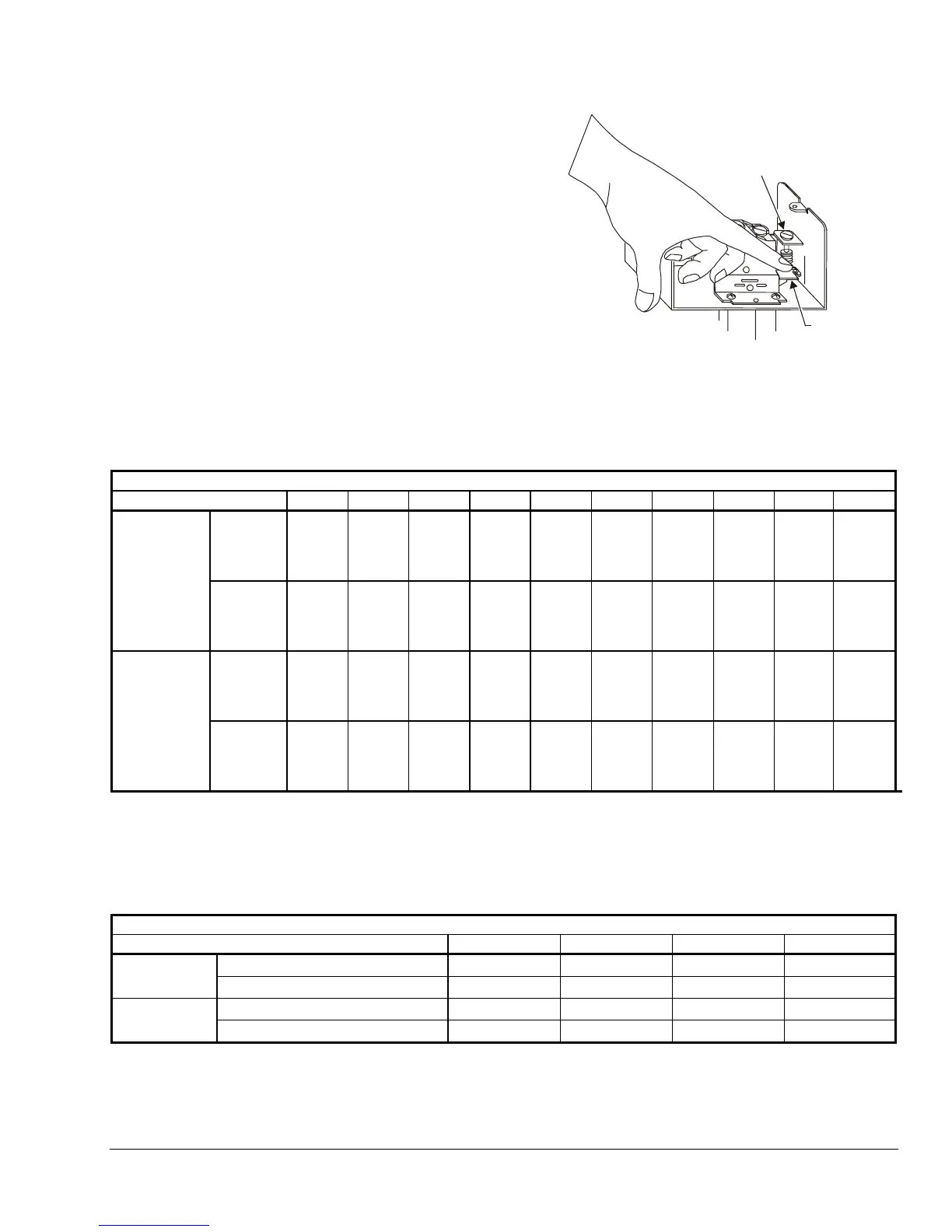

Typical Flow Rates for Standard F61 Flow Switches

Table 3: F61KB, F61LB, and F61MB Models, 1-3 in. Paddles

GPM (m

3

/hr) Required to Actuate Switch

Pipe Size (in.) 1 1-1/4

1

1-1/2

1

22-1/2

2

34

3

5

3

6

3

8

3

Flow

Increase

(R to Y

Closes)

4.20

(0.95)

5.80

(1.32)

7.50

(1.70)

13.7

(3.11)

18.0

(4.09)

27.5

(6.24)

65.0

(14.8)

125

(28.4)

190

(43.2)

375

(85.2)

Minimum

Adjustment

Flow

Decrease

(R to B

Closes)

2.50

(0.57)

3.70

(0.84)

5.00

(1.14)

9.50

(2.16)

12.5

(2.84)

19.0

(4.32)

50.0

(11.4)

101

(22.9)

158

(35.9)

320

(72.7)

Flow

Increase

(R to Y

Closes)

8.80

(2.0)

13.3

(3.02)

19.2

(4.36)

29.0

(6.59)

34.5

(7.84)

53.0

(12.0)

128

(29.1)

245

(55.6)

375

(85.2)

760

(173)

Maximum

Adjustment

Flow

Decrease

(R to B

Closes)

8.50

(1.93)

12.5

(2.84)

18.0

(4.09)

27.0

(6.13)

32.0

(7.27)

50.0

(11.4)

122

(27.7)

235

(53.4)

360

(81.8)

730

(166)

1. Values for 2 in. paddle trimmed to fit pipe.

2. Values for 3 in. paddle trimmed to fit pipe.

3. Values calculated for factory-installed set of 1, 2, and 3 in. paddles.

Table 4: F61KB, F61LB, and F61MB Models, 6 in. Paddles*

GPM (m

3

/hr) Required to Actuate Switch

Pipe Size (in.) 4568

Flow Increase (R to Y Closes) 37.0 (8.40) 57.0 (12.9) 74.0 (16.8) 205 (46.6)

Minimum

Adjustment

Flow Decrease (R to B Closes) 27.0 (6.13) 41.0 (9.31) 54.0 (12.3) 170 (38.6)

Flow Increase (R to Y Closes) 81.0 (18.4) 118 (26.8) 144 (32.7) 415 (94.3)

Maximum

Adjustment

Flow Decrease (R to B Closes) 76.0 (17.3) 111 (25.2) 135 (30.7) 400 (90.8)

* Where paddle size is larger than pipe size, values are for 6 in. paddle trimmed to fit pipe.

Loading...

Loading...