Basic Controls—P352PN Electronic Proportional Plus Integral Pressure Controls for PSI Applications

7

A

dd-on System 350 Modules

The D352 Digital Pressure Display Module, S352AA-2

Stage Module, and Y350R Power Module are designed

to connect together and plug into the P352PN control.

The power module connects to the control via a

connector on the control’s right side. The display

module and stage module connects to the right side of

the power module.

D352 Pressure Display Module

The D352 display module receives its power, pressure,

and setpoint information from the P352PN control. A

3-digit Liquid Crystal Display (LCD) gives continuous

read-out of the sensed pressure. Pushing the PRESS

FOR SETPOINT button on the display module displays

the P352PN control setpoint. Refer to

System 350

D350 Display Modules Product/Technical Bulletin,

LIT-930070

for more information.

Y350R Power Module

The Y350R power module provides a convenient

method of powering System 350 Modules from a

120 or 240 VAC power source. The power module

supplies power to all of the modules. Refer to

System 350 Y350R Power Module Product/Technical

Bulletin, LIT-930090

, for more information.

S352AA-2 ON/OFF Stage Module

The S352AA-2 stage module provides ON/OFF

pressure control based on the P5352PN control

setpoint and the stage module offset. Refer to

System 350 S350A Temperature, S351A Humidity,

and S352A Pressure Stage Modules

Product/Technical Bulletin, LIT-930080

, for more

information.

A

djustments

Use the following procedure to set up and adjust the

P352PN pressure control.

1. Remove its cover by loosening the four captive

cover screws.

2. Set the RA/DA jumper blocks to the desired mode.

Position the jumper blocks vertically for RA or

horizontally for DA mode. See

Reverse or Direct

Acting Mode

section and Figure 2.

3. Adjust the throttling range potentiometer to desired

setting. Rotate clockwise to increase the throttling

range. Refer to

Throttling Range (Proportional

Band)

section and Figure 2.

Note: If the P352PN control is to be used in

proportional plus integral mode, the initial

throttling range adjustment should not be set

below 30 psi for the P352PN-2 model or 60 psi

for the P352PN-3 and P352PN-4 models. A

narrow proportional band used in conjunction

with the integration may result in unstable

control.

4. If minimum output is required, set the minimum

output potentiometer to the desired position. The

10-segment LED bar graph or a voltmeter can be

used to read the minimum output. See

Minimum

Output Adjustment

section and Figure 2.

Note: Before setting the minimum output, verify

that the minimum output potentiometer is

set to zero (turned fully counterclockwise),

and that no LEDs are lit on the LED bar

graph.

For each 10% increase in output, the LED bar

graph will advance one LED segment

(only one bar is lit at anytime). In a milliampere

application, each bar equals 2 mA. In a voltage

application, each bar equals 1 VDC.

Example: To set the control for a minimum output

of 4 mA, slowly turn the minimum output

potentiometer clockwise until the second LED

segment just lights.

5. Adjust the P352PN control to the desired setpoint,

replace cover, and place the system in operation.

Table 3 gives the tolerances for setpoint readings

at mid scale and scale-end.

Note: The D352 Display Module is unaffected by

these tolerance shifts. Use the display module

to achieve the most accurate setpoint

selection.

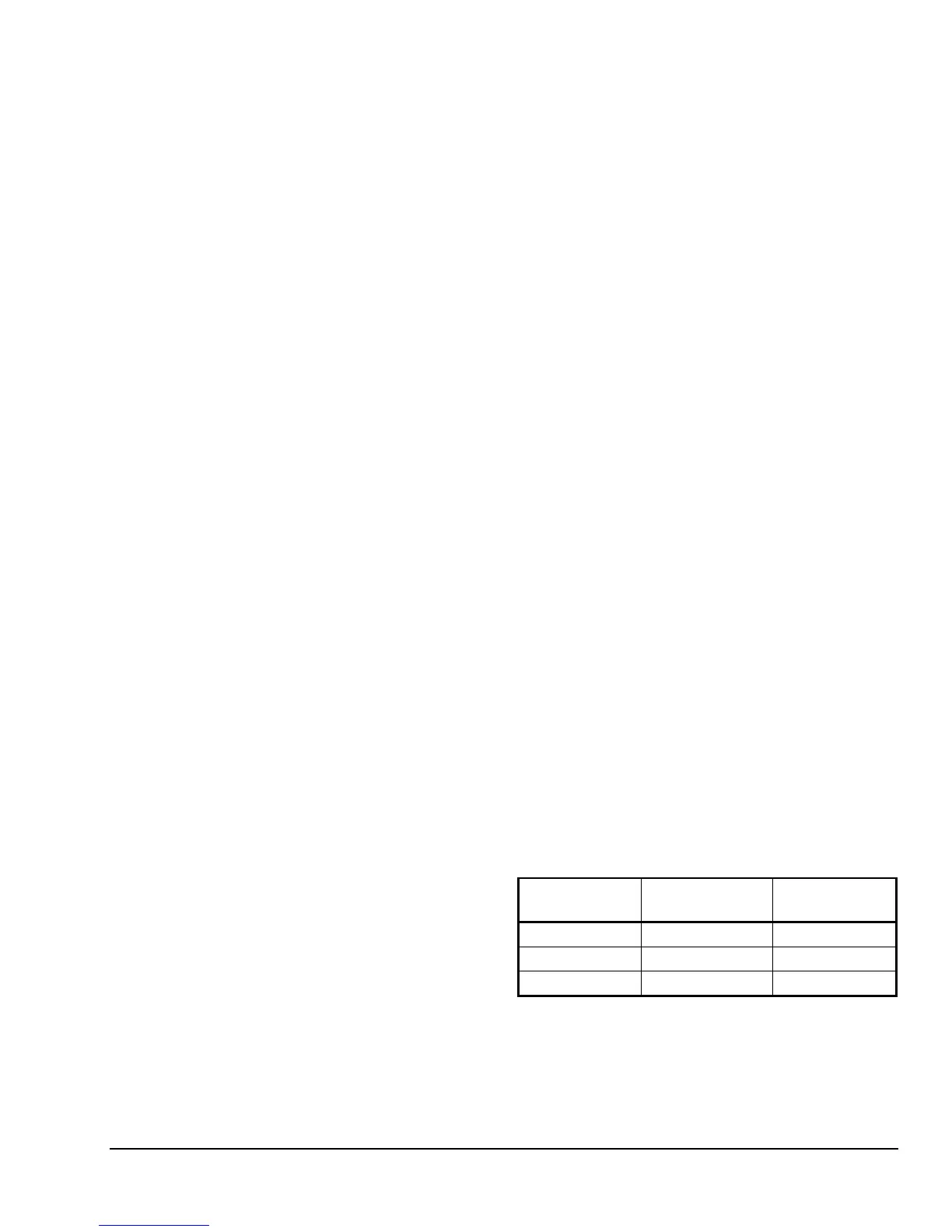

Table 3: Setpoint Mid-scale and Scale-end

Tolerance Values

Control

Model

Mid-scale

Tolerance

Scale-end

Tolerance

P352PN-2

±1.5 psi ±2.5 psi

P352PN-3

±1.5 psi ±3.5 psi

P352PN-4

±3.5 psi ±8 psi

6. Make sure the operating system is stable before

setting the integration constant (if necessary).

Refer to the

Checkout Procedure

section and

Integration Constant DIP Switch Settings

when

setting the integration constant.

Loading...

Loading...