Basic Controls—P352PN Electronic Proportional Plus Integral Pressure Controls for PSI Applications

9

3. Check pressure transducer for proper output

signal voltage.

a. Measure and record the voltage between the

SEN

and the

COM

terminals on the control

terminal block.

V

o

= _______

b. At the same time observe and record the

pressure reading.

psi

T

= _______

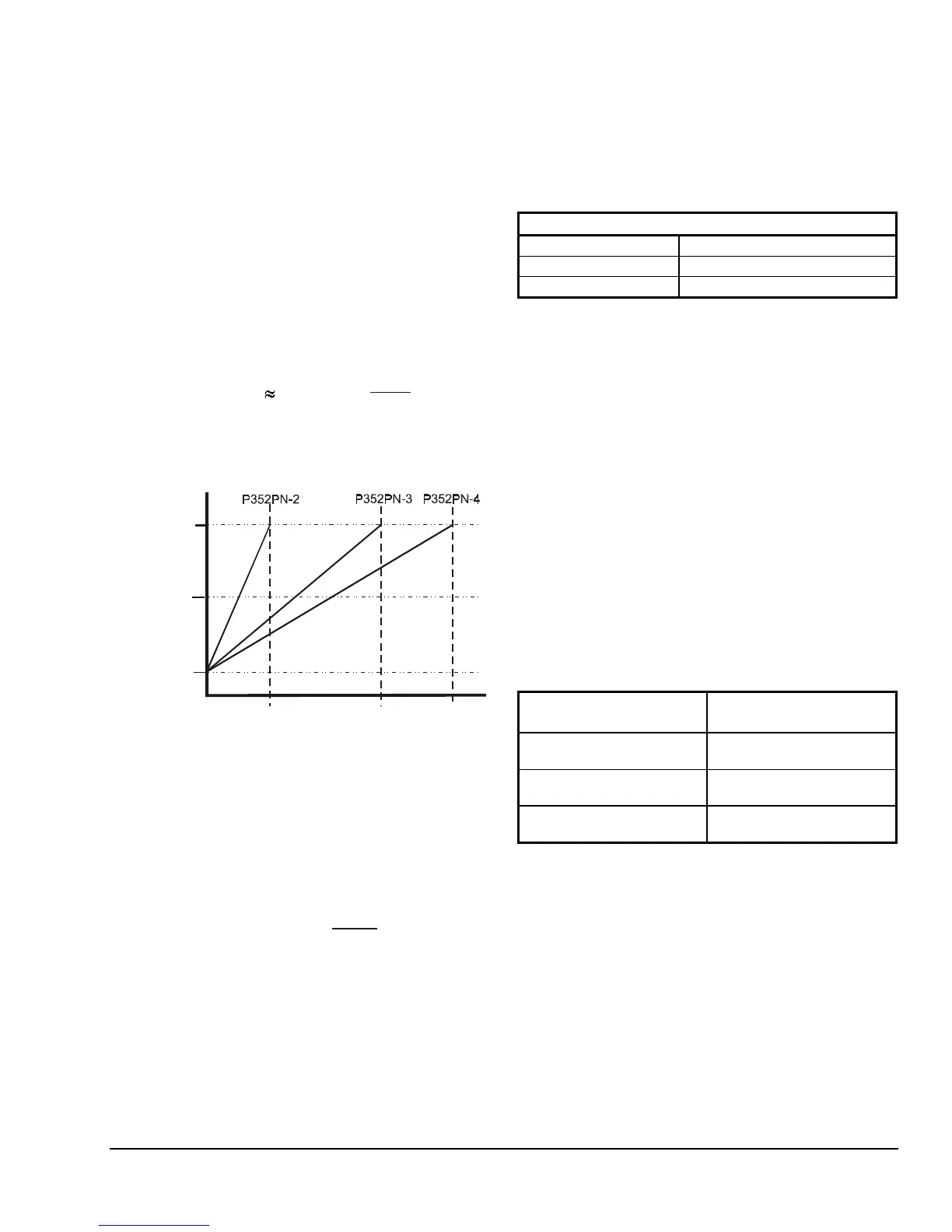

c. The transducer output signal voltage (

V

o

)

increases proportionally to an increase in the

pressure at the transducer (

psi

T

). Use the

graph in Figure 8 to compare the measured

signal voltage to the measured pressure. Or

use the formula below to compare the voltage

and pressure values.

psi

T

(V - 0.5V) x

4V

P

max

o

psi

T

= Pressure measured at transducer

V

o

= Transducer output signal voltage (VDC)

P

max

= Transducer pressure range maximum

100 psi

500 psi

750 psi

(10%)

(90%)

(50%)

Pressure Range

Signal Output Voltage

(% of Supply VDC)

4.5 VDC

2.5 VDC

0.5 VDC

Control Model Number

Figure 8: Transducer Pressure vs.

Output Signal Voltage

Example:

The measured pressure at the gauge is

approximately 245 psi, the measured voltage

is 2.5 VDC (

V

o

), and the transducer’s rated

range is 0 to 500 psi (

P

max

). Use the formula

above to calculate the pressure you would

expect from the measured voltage.

(2.5V - 0.5V) x

4V

500

psi

= 250

psi

Since the measured pressure of 245 psi is

close to the pressure calculated from the

measured voltage (250 psi), the transducer

output voltage should be considered within the

desired range.

4. Check the P352PN control for proper operation.

Perform Steps 1-3 first.

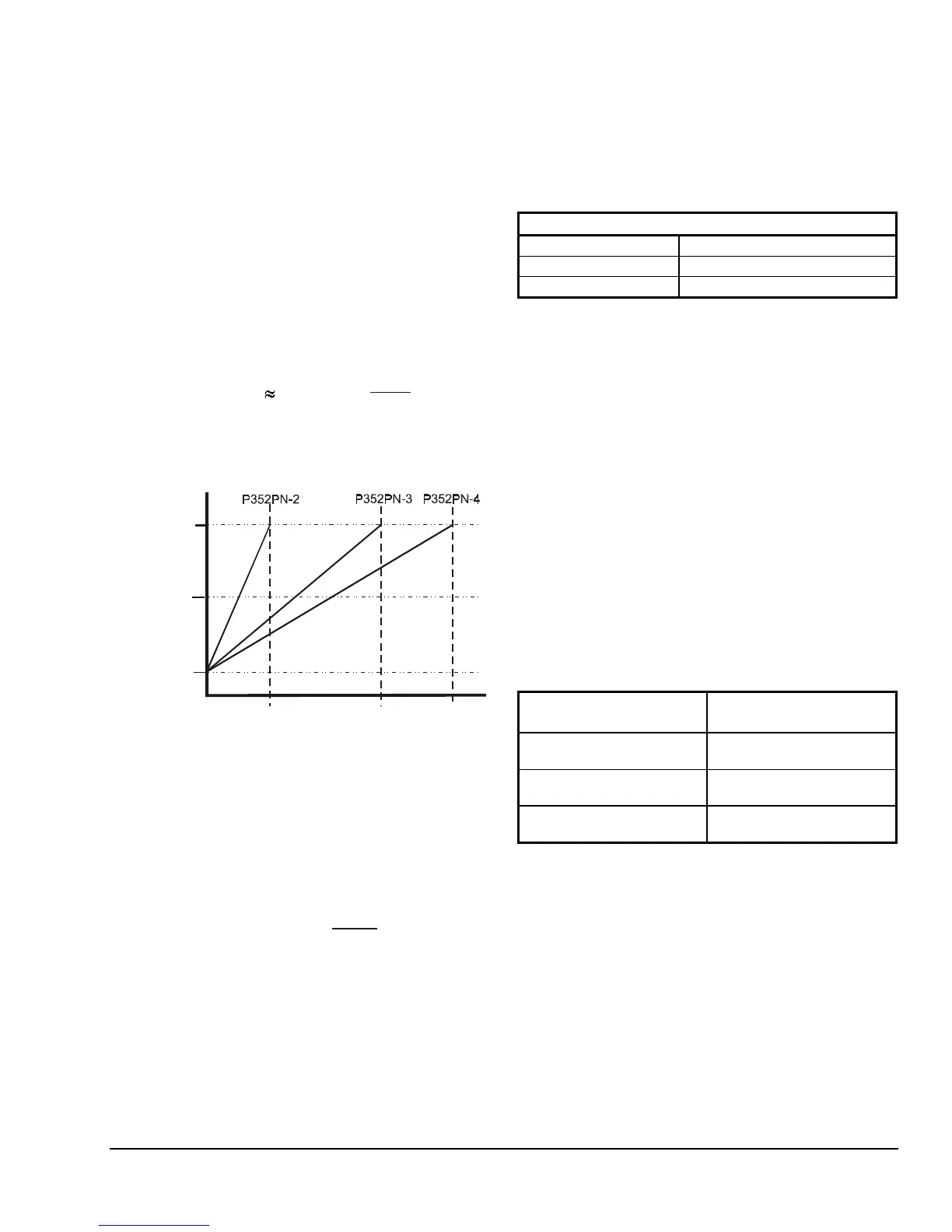

a. Record the current setpoint, integration

constant, and throttling range in Table 4 below.

Table 4: Record of Current Settings

Current P352PN Control Settings

Setpoint

Integration Constant

Throttling Range

b. Set integration constant to OFF (proportional

only). See

Integration Constant

section.

c. Disconnect all power to the system and

control.

d. Disconnect the equipment from the control.

e. Reconnect power to the control.

f. Verify that the power supply and transducer

are connected properly.

g. Use an accurate gauge to take an independent

pressure reading at the transducer. (This

procedure requires a minimum of 30 psi static

pressure at the transducer.)

h. Set the P352PN control to Direct Acting mode.

Refer to Figure 2.

i. Adjust the throttling range potentiometer to

approximately 25 psi.

j. Observe the LED display while adjusting the

setpoint for each of the settings listed in

Table 5. If the display varies substantially from

these values, replace the control.

Table 5: Output at Select Setpoint Settings

Setpoint Setting

Approximate Output

Expected

At or Above Transducer

Reading

No LED bars lit

12 to 13 psi Below

Transducer Reading

4 or 5 LED bars lit

25 psi Below Transducer

Reading

All LED bars lit

k. Reconnect the equipment to the control. Reset

the control to the original settings (Table 4),

and reconnect power to the system.

l. Observe the system for a minimum of three

operating cycles. If the system still does not

perform properly, check application settings,

and replace the control if it does not operate

as expected for those settings.

Loading...

Loading...