10

Basic Controls—P352PN Electronic Proportional Plus Integral Pressure Controls for PSI Applications

5. Check the stage modules for proper operation.

If stage modules are not used, skip this step.

Perform Steps 1-4 first.

a. Determine and record if the control is

in the DA or RA mode of operation.

b. Determine the differential setting.

c. Observe and record the offset setting.

d. Observe and record the system

pressure at the gauge.

e.

If the stage module is in the DA mode

,

adjust the setpoint setting to a value lower than

the observed gauge pressure. If the stage

module LED is not lit, turn the control setpoint

adjustment knob counterclockwise until the

LED lights.

f. With the stage module LED lit, slowly turn the

control setpoint adjustment knob clockwise

(to increase the setpoint setting) until the LED

goes off. Observe the control setpoint, which

should be the same as the gauge pressure

minus the offset setting when the stage

module LED goes off.

g. Next turn the setpoint adjustment slowly

counterclockwise until the stage module LED

lights again. Observe the control setpoint,

which should be equal to the gauge pressure

minus the differential setting and offset setting

when the LED is lit.

h.

If the control is in the RA mode

, adjust the

setpoint setting to a value higher than the

observed gauge pressure. If the stage module

LED is not lit, turn the setpoint adjustment

knob clockwise until the LED lights.

i. With the stage module LED lit, slowly turn the

setpoint adjustment knob counterclockwise

(to decrease the setpoint setting) until the LED

goes off. Observe the control setpoint, which

should be equal to the gauge pressure plus

the offset setting when the LED went off.

j. Next turn the setpoint adjustment slowly

clockwise until the stage module LED lights

again. Observe the control setpoint, which

should be equal to the gauge pressure plus

the offset and differential settings.

6. Check the display module for proper operation.

If a display module is not used, skip this step.

Perform Steps 1-5 first.

a. Check the gauge pressure at the transducer

(psi).

b. If the display module does

not

display the

(approximate) pressure measured at the

gauge, replace the display module.

c. Pressing the button on the display module

should display the current setpoint setting.

d. If the displayed setpoint is out of the control’s

setpoint pressure range (check scale-plate at

the setpoint knob for control’s pressure range)

replace the control.

e. If pressing the SETPOINT button results in a

reading other than the expected setpoint

value, check the setpoint setting and correct if

necessary. If the display continues to read an

incorrect value, replace the display module.

Note: If the control and add-on modules all appear to

be operating properly, but the field device still

does not turn on and off as expected, check

the wiring from the control or stage module to

the field device.

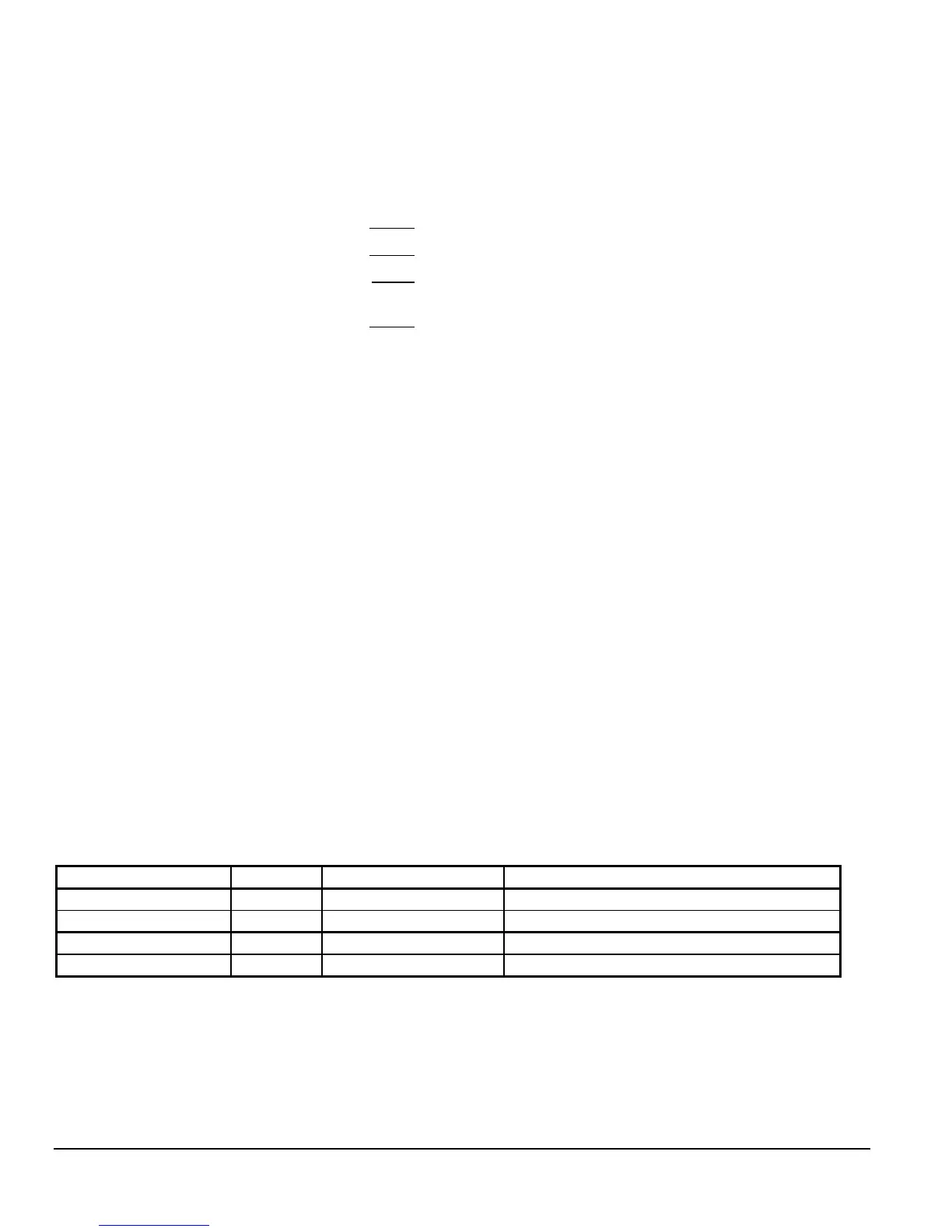

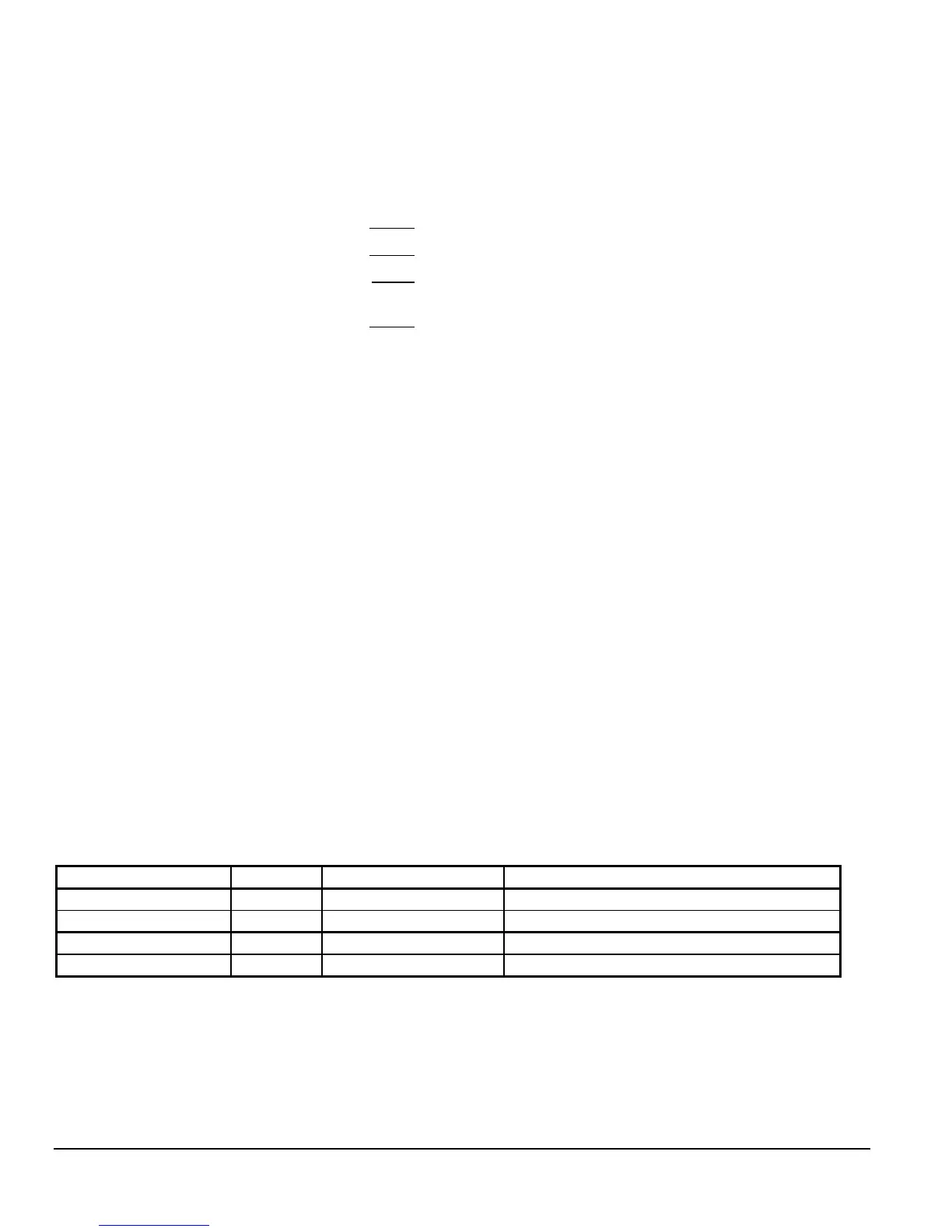

Table 6: S352AA-2 Stage Module Output Relay Troubleshooting

Operating Mode LED N.O. Contact Position Setpoint Setting equals approximately…

Reverse Acting (RA)

ON Closed (gauge pressure)

+

offset

+

differential

Reverse Acting (RA)

OFF Open (gauge pressure)

+

offset

Direct Acting (DA)

ON Closed (gauge pressure)

-

offset

-

differential

Direct Acting (DA)

OFF Open (gauge pressure)

-

offset

R

epairs and Replacement

Do not make field repairs or perform calibration. The

P352PN Pressure Controls and the P399 Transducer

are available through local Johnson Controls

representatives.

Loading...

Loading...