P—P70, P72, and P170 Controls for Dual Pressure Applications Product/Technical Bulletin 7

IMPORTANT: Use the pressure control settings

recommended by the

manufacturer of the controlled

equipment. Do not exceed the

pressure ratings of the controlled

equipment or any of its

components when checking

pressure control operation or

operating the controlled

equipment.

IMPORTANT: After installing and adjusting

pressure control, and before

leaving installation, cycle the

controlled equipment several

times (at least three) at normal

operating conditions. Use reliable

pressure gauges to verify proper

control settings and equipment

operation.

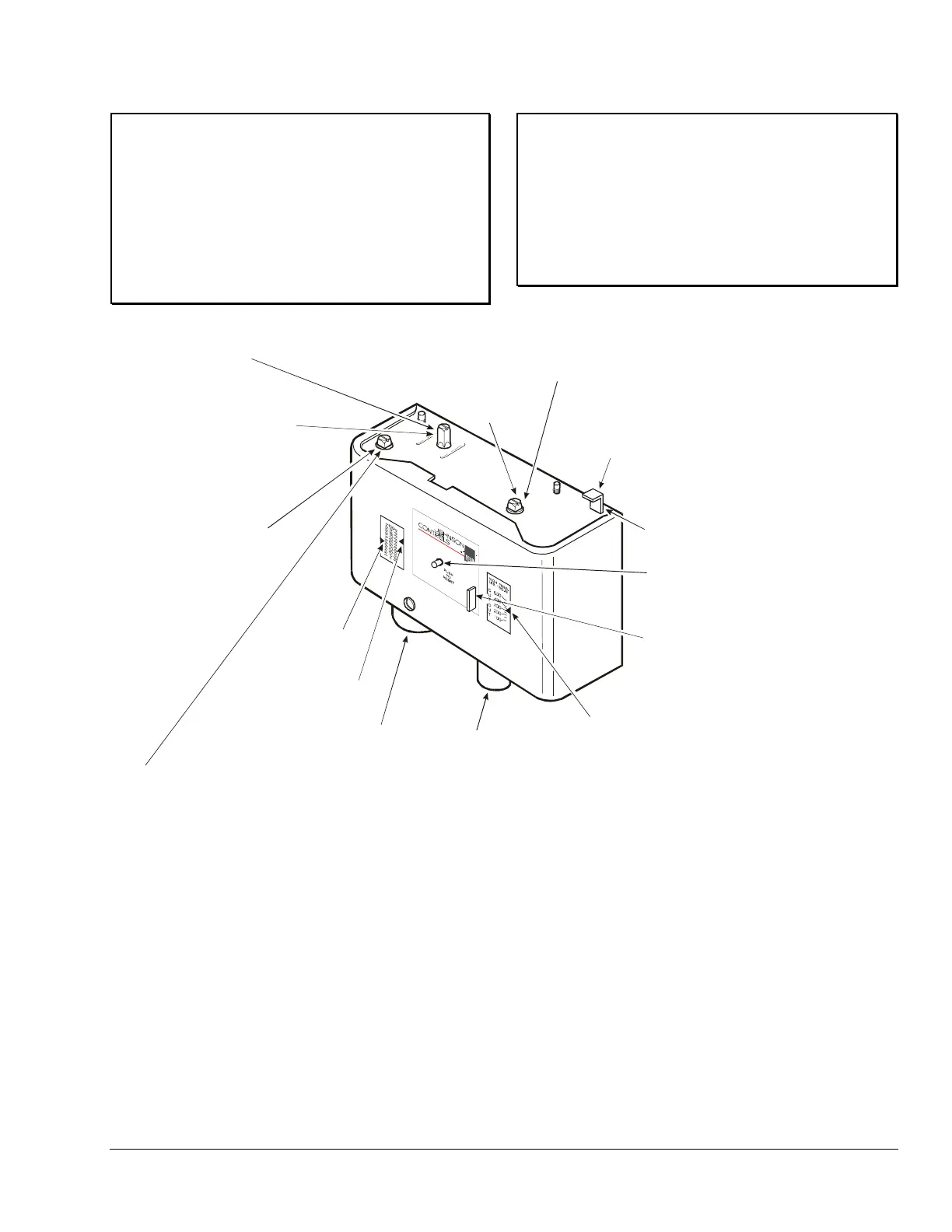

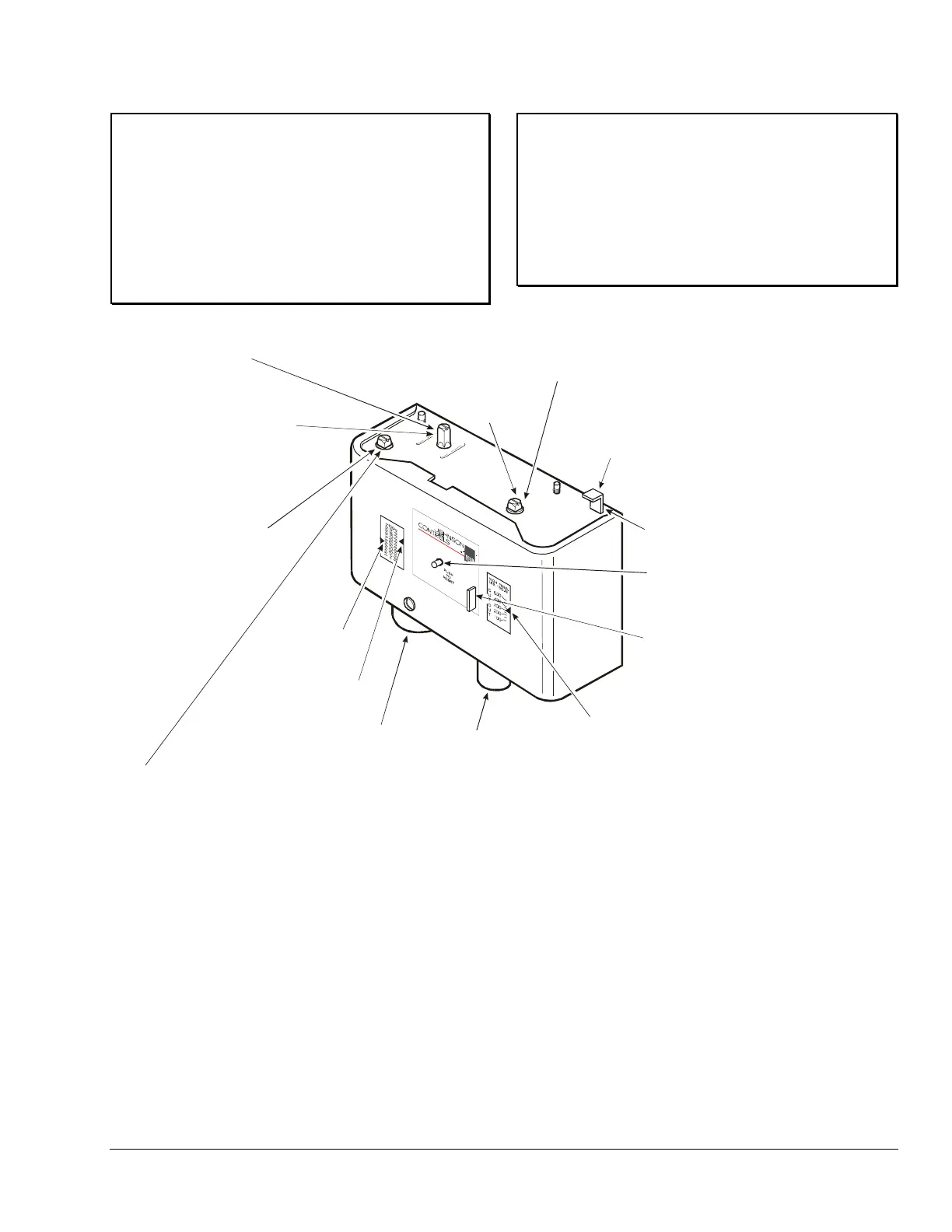

Step 1. Set low side CUT IN by adjusting low side range screw.

Turn screw clockwise to raise the CUT IN setpoint.

Turn screw clockwise to lower the CUT IN setpoint

All-Range Controls:

MICRO-SET Controls:

.

Step 2. Adjust the differential screw.

Turning the differential screw changes the

CUT OUT setpoint. Turn screw clockwise to raise CUT OUT setpoint.

Turning the differential screw changes the

differential setting. Turn screw clockwise to increase differential setting.

All-Range Controls:

MICRO-SET Controls:

Step 3. Set high side CUT OUT setpoint by

adjusting high side range screw.

Turn screw clockwise to raise the

CUT OUT setpoint. (High side

differential setting is fixed.)

Step 4. Set reset operation (on P70S

and P170S models only) for

high side automatic reset or

manual reset lockout.

(See Figure 11.)

Low Side

Range Screw

Differential Screw

(Low Side Only)

Low Side CUT OUT

or DIFFERENTIAL

Pointer

Low Side CUT IN

Pointer

High Side

Range Screw

High Side CUT OUT

Pointer

Low Side

Bellows

High Side

Bellows

Manual Reset Button for P70M, P170M,

P72M, P70Q, and P170Q Models

High Side Manual Reset Only)

(

Manual Reset Button for P70N, P170N,

P72N, P70R, and P170R Models

(Combination Low Side and High Side

Manual Reset)

Manual Reset Button for P70S and

P170S Models (Convertible High Side

Manual or Automatic Reset)

or

or

Figure 10: Adjusting the Dual Pressure Controls

Manual Reset Operation

Pressure controls with the Manual Reset option lock

out when they reach the CUT OUT pressure setpoint

and must be manually reset by the user to restart the

controlled equipment. The manual reset mechanism is

“trip-free” and cannot be overridden by blocking or

tying the reset button down.

On equipment with locked out controls, first determine

and remedy the cause of the lockout before

proceeding.

When lockout is caused by the control’s low side

CUT OUT, allow the sensed pressure to raise to the

CUT IN setpoint.

When lockout is caused by the control’s high side

CUT OUT, allow the sensed pressure to drop at least

70 psig below the CUT OUT setpoint.

After the sensed pressure has reached the desired

pressure (as described above), press and release the

Reset button on the front of the control to restore

operation of the controlled equipment.

Loading...

Loading...