900590-UIM-B-0613

2

INSPECTION

As soon as a coil is received, it should be inspected for possible dam-

age during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s delivery receipt. A separate request for

inspection by the carrier’s agent should be made in writing. See Local

Distributor for more information. Check drain pan for cracks or break-

age.

CLEARANCES

During Installation

Clearance must be provided for:

1. Refrigerant piping and connections

2. Maintenance and servicing access - including cleaning the coil

3. Condensate drain line

4. Filter removal / change

5. Removal of coil assembly

LIMITATIONS

These coils should be installed in accordance with all national and local

safety codes. Check Tables 2, 3, and 4 for operating limitations.

SECTION III: COIL METERING DEVICES

The coil will require a TXV to be installed in the field. Refer to installa-

tion manual with TXV kit. It is recommended to install the TXV kit prior

to installation of coil and brazing line sets.

TXV METERING DEVICE

Please refer to Tables 1 and 2 to verify proper and recommended line

set sizes and that this is a valid system match for the AC or HP unit

installed.

The temperature sensing bulb should be attached to the suction line

set. Refer to Figure 3.

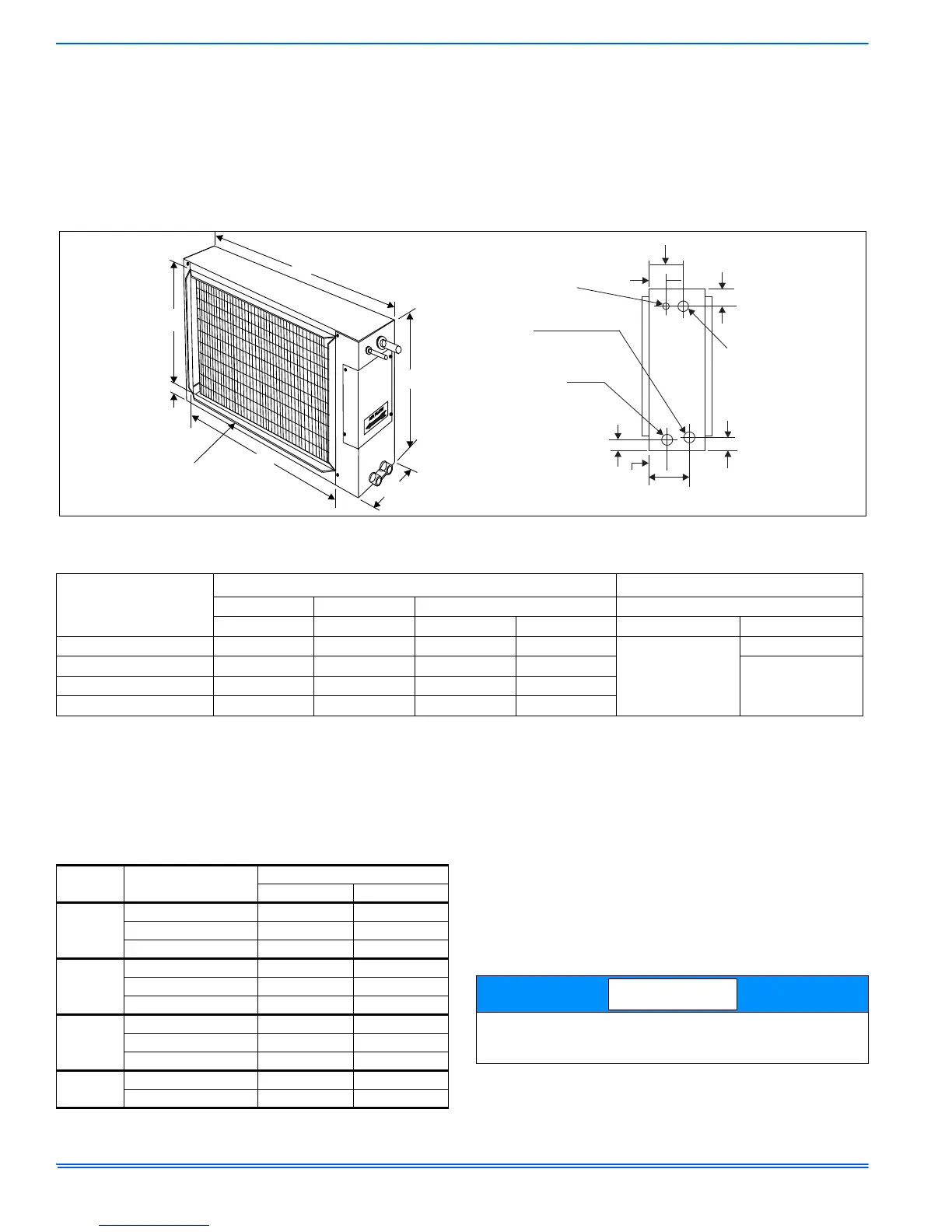

FIGURE 2: Coil - HD

1-3/4

D

5-5/8

A

B

C

3-3/4

2-5/8

1-3/8

OPENING

FOR

VAPOR

CONN.

OPENING

FOR

LIQUID

CONN.

OPENING

FOR

3/4 NPT

SECONDARY

DRAIN CONN.

OPENING

FOR

3/4 NPT

PRIMARY

DRAIN CONN.

7/8

1-7/8

4-1/8

1-3/8

OUTLET SAME

SIZE AS INLET

(3/4” FLANGE)

TABLE 1:

Dimensions

Models

Dimensions

1

Refrigerant Connections

2

Height Width Opening Widths Line Size

ABCDLiquidVapor

HD24S 24 28-3/4 21-5/8 23-3/4

3/8

3/4

HD36S 28 28-3/4 25-5/8 23-3/4

7/8HD48S 28 34-3/4 25-5/8 29-3/4

HD60S 30 34-3/4 27-5/8 29-3/4

1. All dimensions are in inches.

2. Refrigerant line sizes may require larger lines for extended line lengths. See Application Data part number 247077.

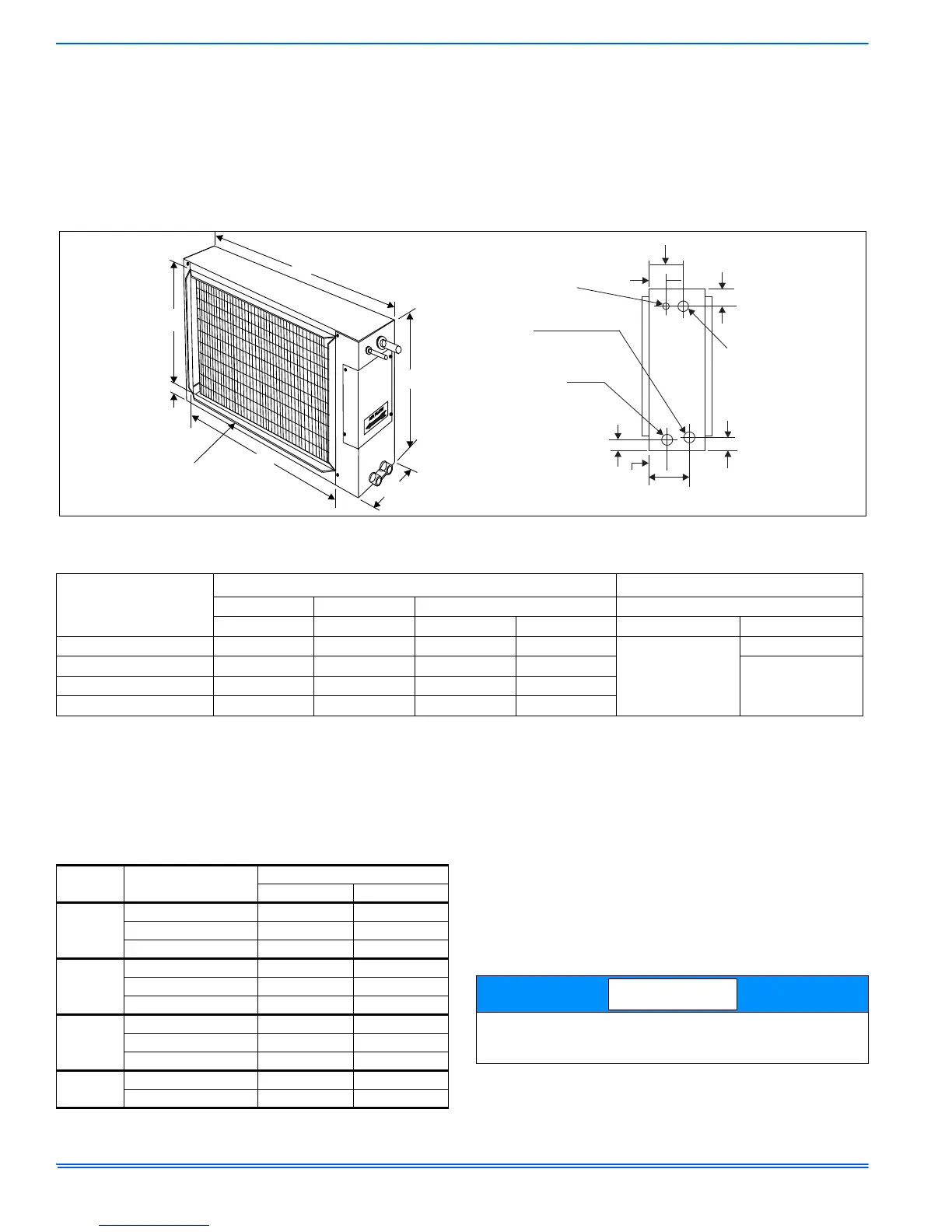

TABLE 2:

Coil Air Flow Limits

Coil

Size

Outdoor Unit

Tons

CFM Limits

Minimum Maximum

24

1 350 450

1-1/2 525 675

2 700 900

36

2 700 900

2-1/2 875 1125

3 1050 1250

48

3 1050 1250

3-1/2 1225 1575

4 1400 1750

60

4 1400 1750

5 1750 2200

For models that have factory installed TXV’s, take caution not to apply

high temperatures to the TXV assembly or equalizer line while braz-

ing.

Loading...

Loading...