900590-UIM-B-0613

3

COIL INSTALLATION

These horizontal coils are designed for installation with a horizontal

(gas or oil fired) furnace or modular blower. A minimum 45° transition

must be field fabricated to allow proper air distribution through the coil.

Airflow direction must be as shown in Figure 4.

Connect ductwork/transition only to coil duct flanges. DO NOT drill

holes in coil cabinet.

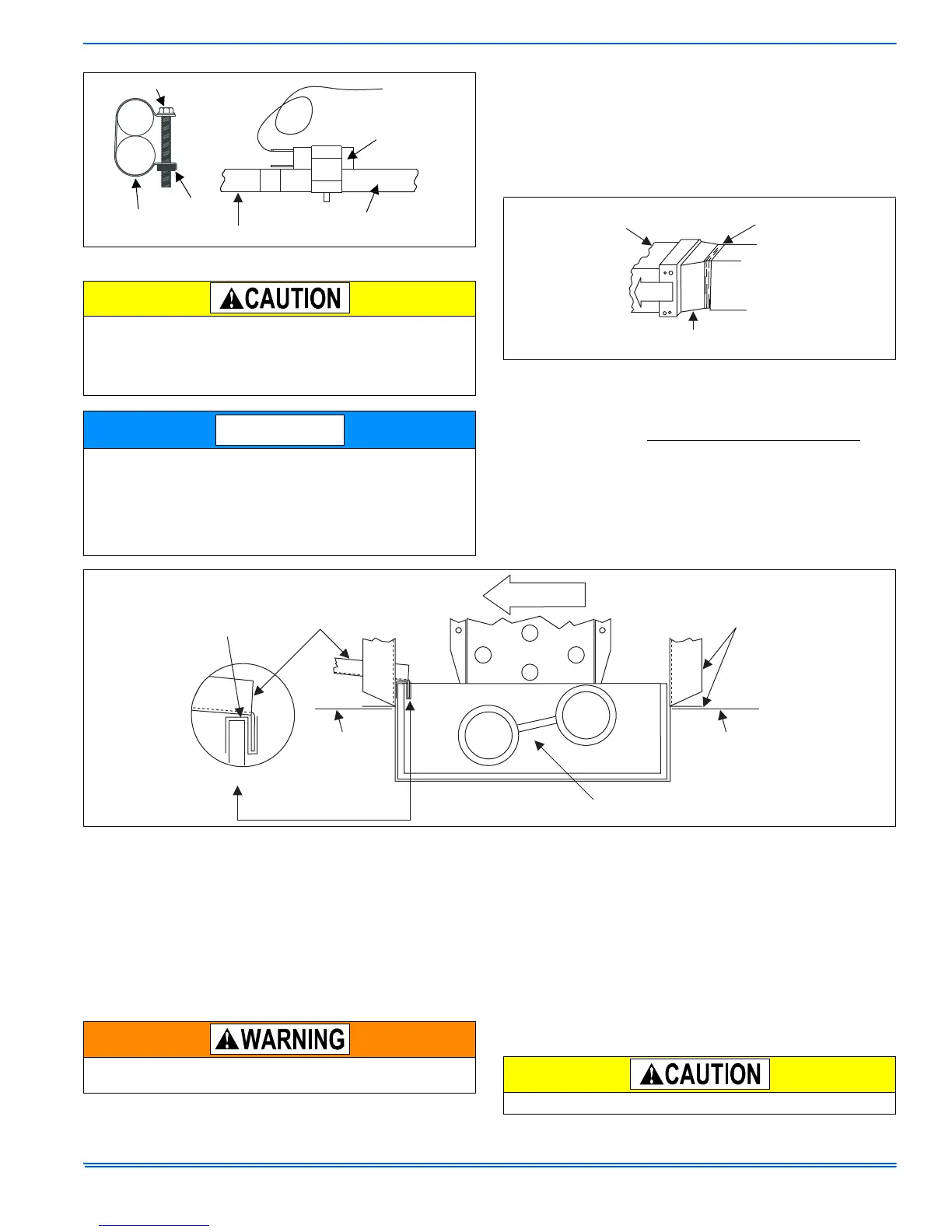

DRAIN PAN EXTENSION INSTALLATION

These coils are shipped with a drain pan extension fastened to the air

leaving side duct flanges. Drain pan extension must be removed.

Install

coil and refasten the extension to the air leaving side of the coil drain

pan as shown in Figure 5, before completing ductwork. The extension

will extend into the duct work as shown.

SECTION IV: DUCT CONNECTIONS

This coil is suited for horizontal applications only.

The vast majority of problems encountered with combination heating

and cooling systems can be linked to improperly designed or installed

duct systems. It is therefore highly important to the success of an instal-

lation that the duct system be properly designed and installed.

Use flexible duct collars to minimize the transmission of vibration/noise

into the conditioned space.

Where return air duct is short, or where sound may to be a problem,

sound absorbing glass fiber should be used inside the duct. Insulation

of duct work is a must where it runs through an unheated space during

the heating season or through an uncooled space during the cooling

season. The use of a vapor barrier is recommended to prevent absorp-

tion of moisture from the surrounding air into the insulation. The supply

air duct should be properly sized by use of a transition to match unit

opening. All ducts should be suspended using flexible hangers and

never fastened directly to the structure. Duct work should be fabricated

and installed in accordance with local and/or national codes. This

includes the standards of the National Fire Protection Association for

Installation of Air Conditioning and Ventilating Systems, NFPA No. 90B.

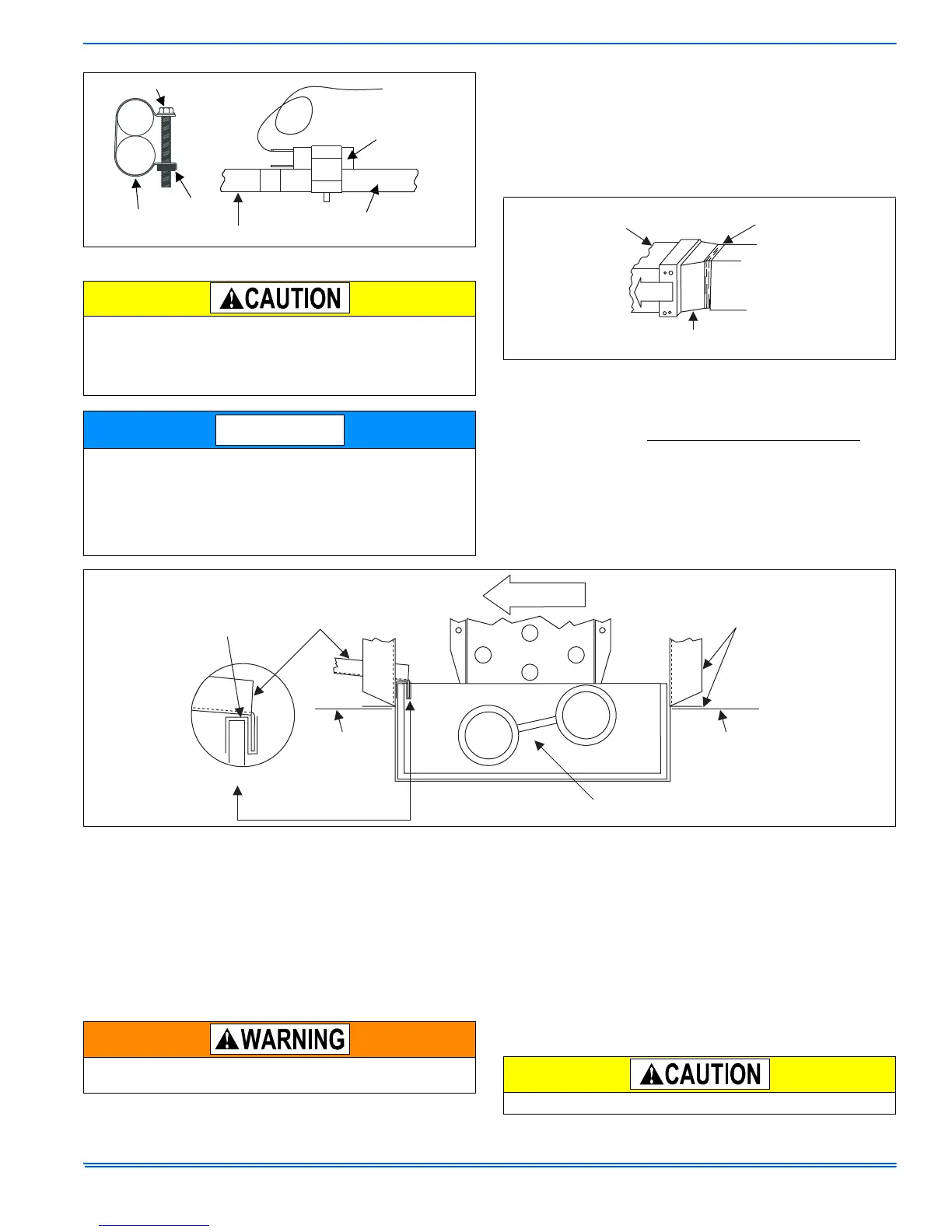

FIGURE 3: Proper Bulb Location

COIL UNDER PRESSURE.

Relieve pressure by depressing schrader core. Coil may have factory

installed TXV or may require TXV to be added. See outdoor unit doc-

umentation for correct TXV to be used. Refer to coil nameplate for

TXV identification for this unit.

The coil should be open to the air for no more than 2 minutes to keep

moisture and contaminates from entering the system. If the coil can-

not be brazed into the refrigeration system in that time, the ends

should be temporarily closed or plugged. For a short term delay, use

masking tape over the ends of the copper tubing to close the tube to

the air. For a longer term delay, use plugs or caps. There is no need

to purge the coil if this procedure is followed.

TXV BULB

(Cover completely

with insulation)

SCREW

CLAMP

NUT

SUCTION HEADER

SUCTION LINE

(FIELD INSTALLED)

FIGURE 4: Horizontal Coil Installation

AIR

FLOW

SUPPLY

DUCTWORK

FLEXIBLE

CONNECTIONS

MINIMUM 45°

TRANSITION

FIGURE 5: Drain Pan Extension Installation

AIR FLOW

COIL

DUCTWORK

DETAIL “A”

DUCTWORK

DRAIN PAN

EXTENSION

“S” CLIP

FASTENERS

(3)

COIL FLANGES

FOR DUCTWORK

FASTENING

DRAIN PAN

Use 1/2" screws to connect ductwork to unit. If pilot holes are drilled,

drill only through field duct and unit flange.

Equipment should never be operated without filters.

Loading...

Loading...