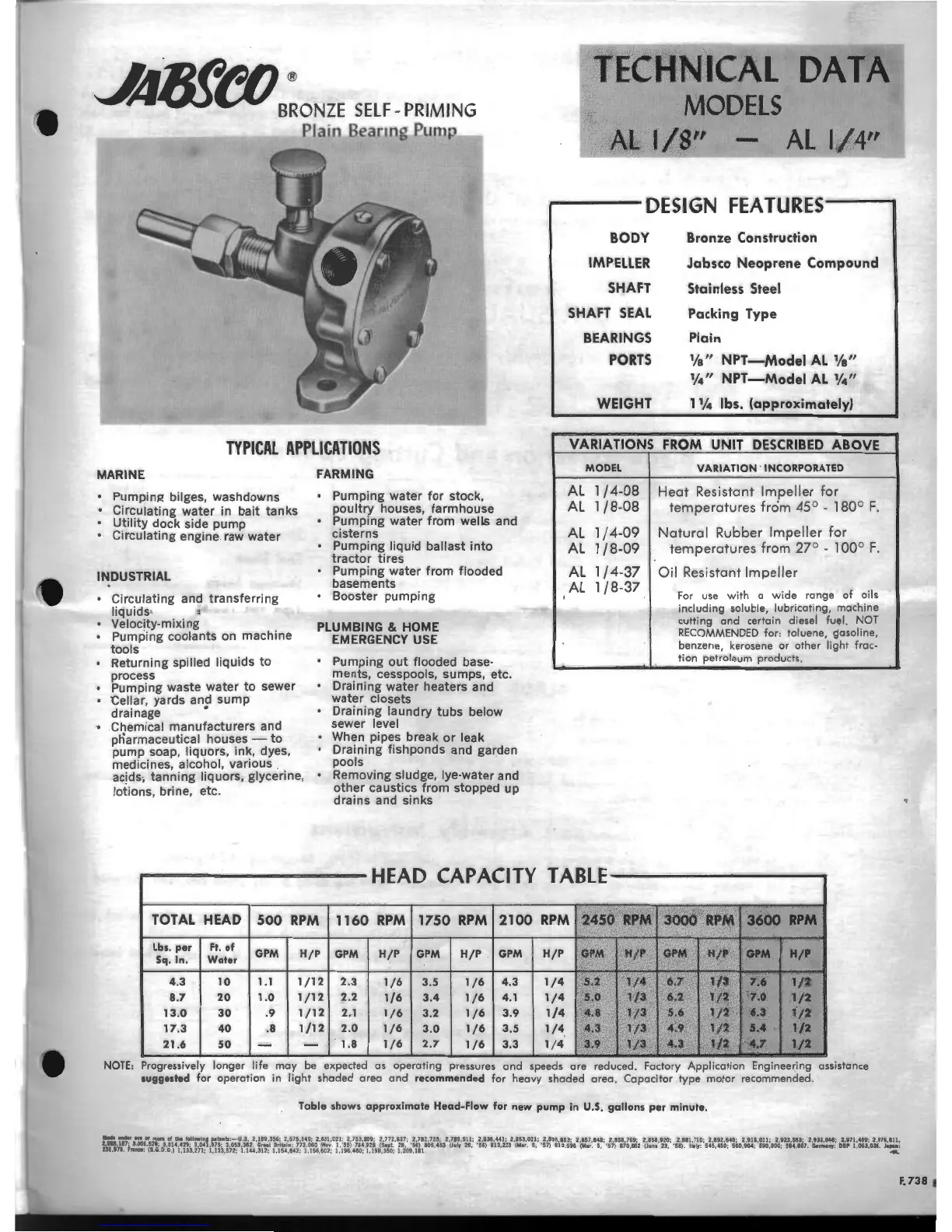

AMCO

B:ONZE

SELF-

PRIMING

Plain Bearmg

Pump

TYPICAL

APPLICATIONS

MARINE

• Pumping

bilges, washdowns

•

Circulating

water

in

bait

tanks

•

Utility

dock

side

pump

Circulating engine raw

water

INDUSTRIAL

•

Circulating

and

transfe

rring

liquids.

Velocity-

mixing

• Pumping coolants on machine

tools

• Returni

ng

spilled

liquids

to

process

• Pumping waste

water

to

sewer

Cellar, yards and

sump

drainage •

• Chemical

manufacturers

and

ptiarmaceutical houses -

to

pump

soap, liquors,

ink

, dyes,

medicines, alcohol, various .

acjds,

tanning

liquors, glycerine,

lotions, brine, etc.

FARMING

•

Pumping

water

for

stock,

poultry

houses,

farmhouse

•

Pumping

water

from

welLs

and

cisterns

Pumping

liquid

ballast

into

tractor

tires

Pumping

water

from

flooded

basements

Booster

pumping

PLUMBING & HOME

EMERGENCY USE

•

Pumping

out

flooded base-

ments, cesspools, sumps, etc.

Draining

water

heaters and

water

closets

• Draining

laundry

tubs

below

sewer level

When pipes break

or

leak

Draining fishponds and garden

pools

• Removing sludge, lye-water and

other

caustics

from

stopped up

drains

and sinks

TECHNICAL

DATA

MODELS

Al 1/4"

----DESIGN

FEATURES-____,

BODY

Bronze

Construction

IMPELLER

Jabsco

Neoprene

Compound

SHAFT

Stainless

Steel

SHAFT

SEAL

Packing

Type

BEARINGS

Plain

PORTS

%"

NPT-Model

AL

%"

1f4"

NPT-Model

AL

%"

WEIGHT

1

%

lbs.

(approximately)

VARIATIONS FROM UNIT

DESCRIBED

ABOVE

MODEL

AL

1/4-08

AL

1/8-08

AL

1 I

4-09

AL

l

/8-09

AL

1/4-37

AL

1

/8

-

37

VARIATION

INCORPORATED

Heat

Res ista

nt

Impeller

for

temperatures

from

45

° -

180

° F.

Natural

Rubber

Impeller

for

temperatures

from

27

° - l

00

° F.

Oil

Resi s

tant

Impeller

For

use

w ith a wide

rang

e of oils

including

soluble,

lubricating

, m

ac

hine

cutting

and

certain

diesel

fuel_ NOT

RECOMMENDED for, tolue

ne

,

ga

so

li

ne

,

benzene

,

keros

e

ne

or

ather

light

fra

c-

tion

pe

troleum

products

.

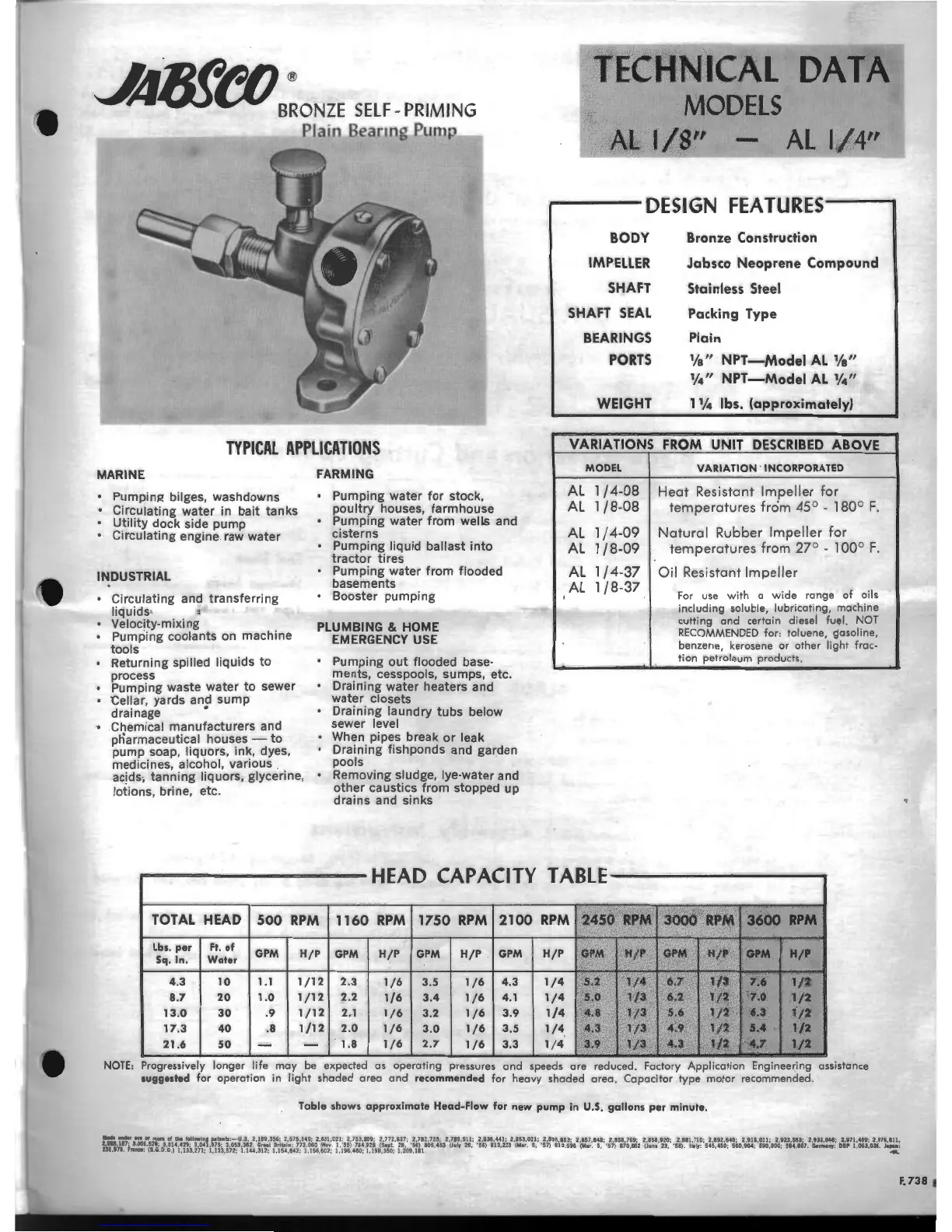

HEAD

CAPAC

TY

T B I

A

LE

TOTAL

HEAD

500

RPM

1160

RPM

1750

RPM

2100

RPM

2450

RPM

3000

RPM

3600

RPM

Lbs

.

per

Ft

.

of

GPM

H/P

GPM

H/P

GPM

H/P

GPM

H/P

GPM

H/P

GPM

H/P

GPM

H/P

Sq. ln.

Water

4.3

10

1.1

1/12

2.3

1/6

3.5

1/6

4.3

1/4

5.2

1/4

6,1

1/3

1.6

1/2

8.7

20

1.0

1/12

2.2

1/6

3.4

1/6

4.1

1/4

5.0

1/3

6.2

1/2

7.0

1/2

13.0

30

.9

1/12

2.1

1/6

3.2

1/6

3.9

1/4

4.8

1/3

5.6

1/2

6.3

t'/2

17

.3

40

.8

1/12

2.0

1/6

3.0

1/6

3.5

1/4

4.3

1/3

4.9

1/2

5.4

1/2

21.6

so

-

-

1.8

1/6

2.7

1/6

3.3

1/4

3.9

1/3

4.3

1/2

4.1

1/2

NOTE

, Progressrvely

longer

lrfe

may

be

expected a s

operatrng

pressures

and

speeds

are

reduced.

Factory

Applrcatron

Engineering

assistance

suggested

for

operat

i

on

in

light

shaded

area

a

nd

recommended

for

hea

vy

shaded

area

.

Cap

a citor

type

motor

recommended

.

Table

·S

hows

approximate

Head-Flow

for

new

pump

in U.S.

gallons

per

minute.

F,738

Loading...

Loading...