Selecting the right Template for your Project

Set up your CLINCHER and fence or CabinetMaker's System as described

earlier. All of the instructions for making joints with the CLINCHER use the

true-center zero

method which means that all fence settings are referenced

from the center of the router bit. Therefore, all cut lines on all CLINCHER

templates represent the exact center of the router bit.

Use high quality router bits for your joinery. The better bits will normally be

made to tighter tolerances and will cut cleaner. Diameter tolerance is VERY

critical when making box joints.

Getting Started

Templates slide into one of the auxiliary slots on CLINCHER carriage.

Carefully insert the selected template into slot at right end of CLINCHER.

Keep fingers close to machine end as you slide in template to prevent

bending or kinking. If you initially have difficulty inserting the template into a

slot, gently bow it between your fingers along its length. Once in the slot you

can move the template with finger pressure on its top. Its exact position will

be determined during the centering operation for symmetry.

Installing Clincher Templates

Using Clincher Templates

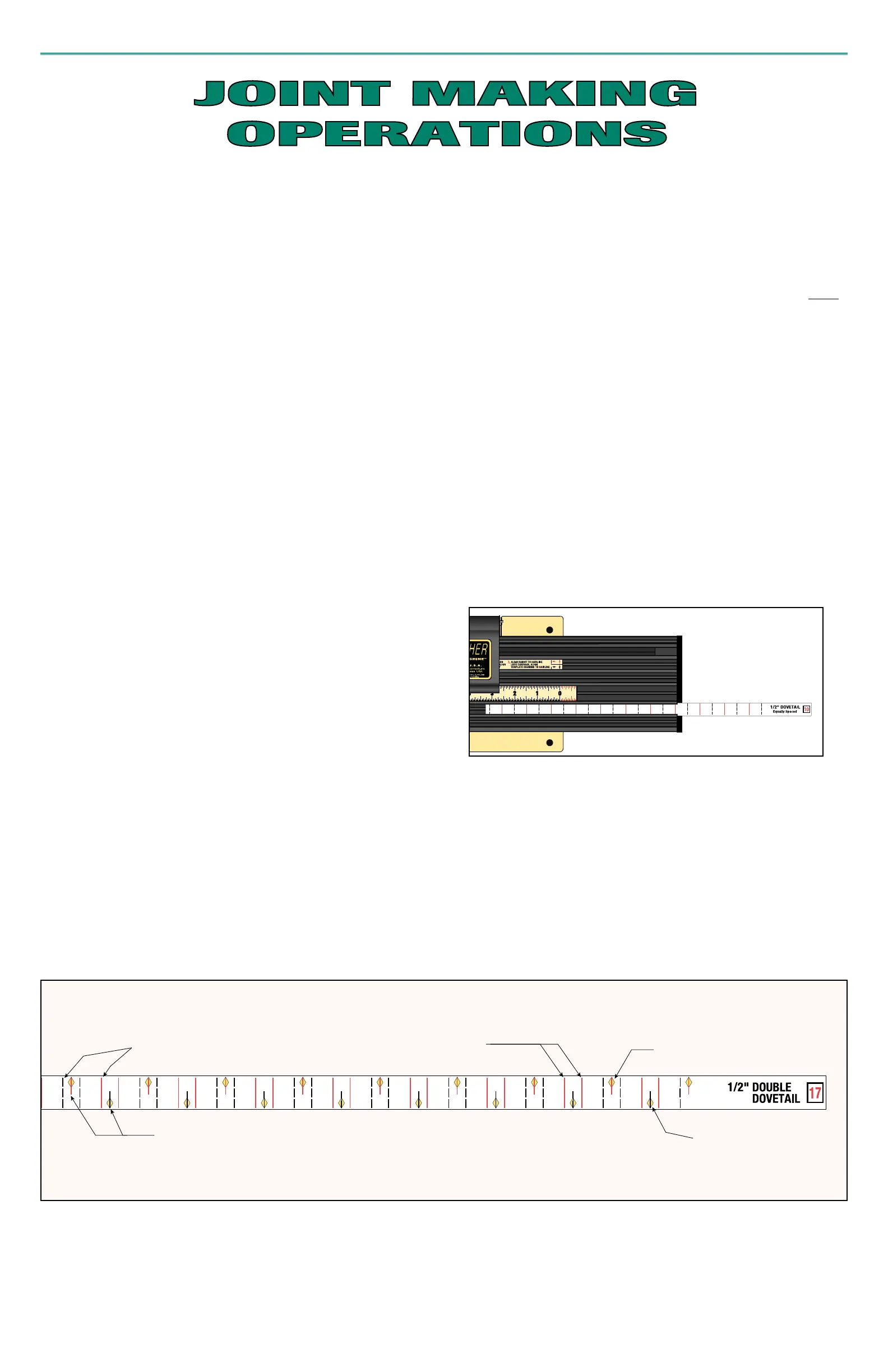

Once installed, making any joint is simply a matter of setting CLINCHER to

the pre-marked templates lines and making the cut. Templates for conven-

tional (non-inlay) dovetail and box joints use two series of pre-marked lines

for cuts; RED solid lines and BLACK dashed lines. The double-dovetail

patterns have four series of pre-marked lines while the double box joint and

the Boxtail™ patterns have six series of lines on one template. Except for

the

3

/

8"

Boxtail which requires two templates to complete its series of cuts,

Half Lines

(RED and BLACK, upper and lower) represent settings for making

the center (or inlay) sections in these decorative joints. The series of RED

or BLACK cut lines to use for the Pins and Tails can only be determined

by following the procedure in the next section

“Determine Pin and Tail

Cuts”

, on page 12.

The variably spaced and double inlay patterns which require cuts wider than

the router bit are accomplished by making successive passes with the cutter.

This is accomplished using side-by-side cut lines on these templates

Yellow diamonds on some templates are alignment marks which are used to

center your workpiece to achieve symmetry.

MAKING THE PERFECT JOINT

Once you have selected your project and the stock thickness has been

determined, select the type of joint that you want. Usually the design and

scale of your project, including the stock thickness and board widths to be

joined, will dictate the appropriate size router bit and type of joint to use.

For example, a small jewelry box would look better with small joints, perhaps

decorative, while a blanket chest made with much larger joints would have a

better appearance. Narrow workpieces would usually call for an equally

spaced pattern while with wide boards, variably spaced patterns might make

a better appearing joint. Each template in this book has a corresponding set

of full size plans for the joint which it produces to help you make your

selection. Each plan will show a diagram of the template, the joint that it will

make, plus other information such as pattern spacing, router bit diameter,

approximate settings for depth of cut, wall thickness of double-inlay patterns

and other notes to successfully complete the joint. Also listed is the metric

equivalent for all bit diameters which are available internationally. It is

suggested that you refer to the plan page before making final selection

because not all board widths may work well with your desired pattern. You

may have to revise your board width or change your template selection.

The decorative nature of double-inlay joints requires that certain board widths

be used in order to produce a finished joint that is both visually pleasing and

structurally sound. Unlike conventional joint patterns, the assignment of

template cut lines for all cuts have been predetermined for these board

widths. Charts on their respective plan pages will aid in selecting the board

width and corresponding symmetry mark for template alignment.

Full length cut lines used

for Pin and Tail cuts.

Side-by-side cut lines create

a cut wider than router bit.

Half lines used for making

center section cuts for

double inlay joints.

Upper symmetry diamond

(alignment mark).

Lower symmetry diamond

(alignment mark).

10

Loading...

Loading...